Method for efficiently decomposing and recycling valuable metal in copper slag

A valuable metal and copper recovery technology is applied in the treatment of copper slag, efficiently decomposes and recovers valuable metals in copper slag, and can solve the problems of lack of environmental friendliness, separation effect, and ineffective recycling of iron resources in slag, etc. Achieve the effect of improving decomposition efficiency, improving secondary resource utilization, and improving oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

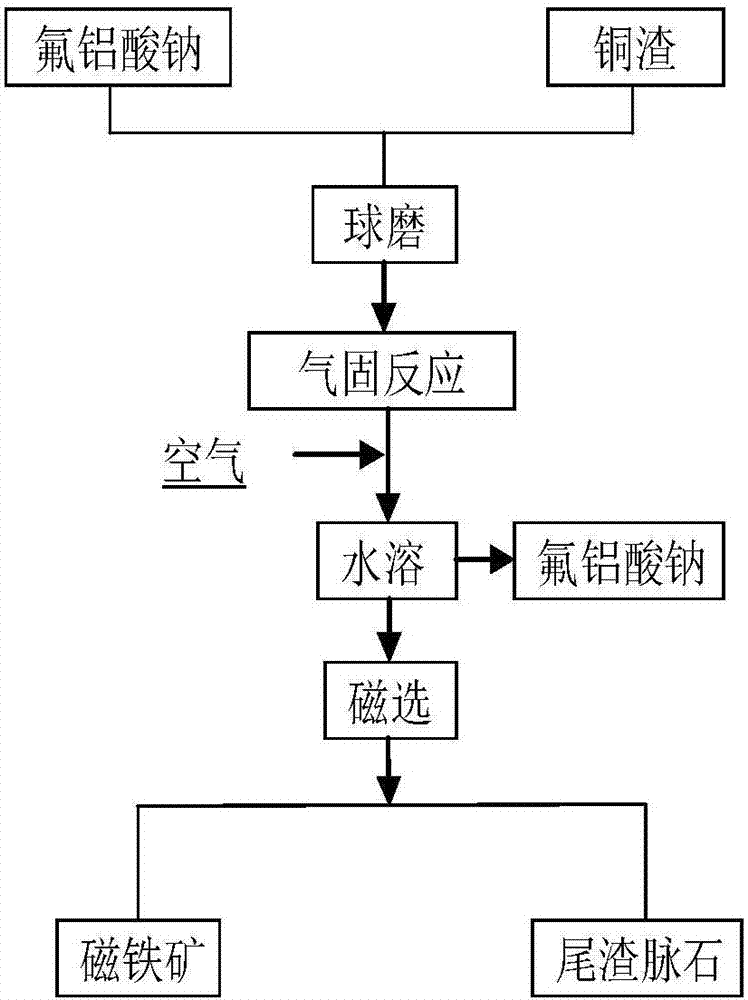

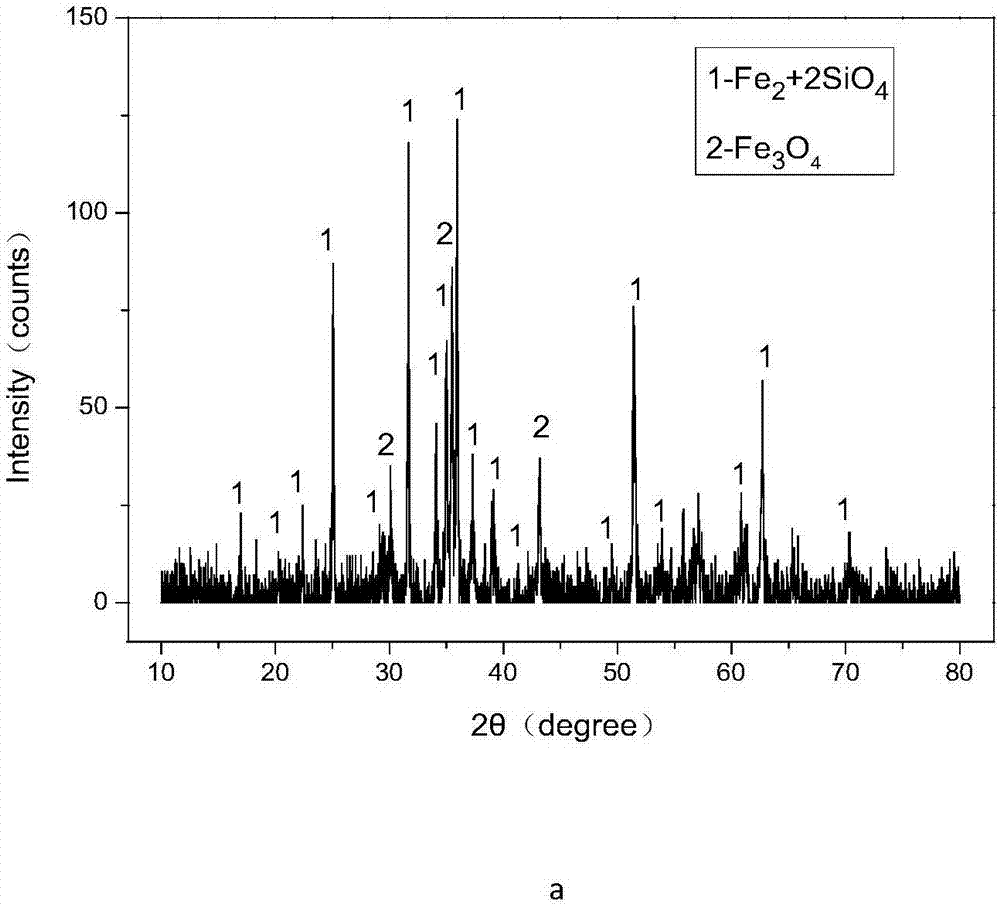

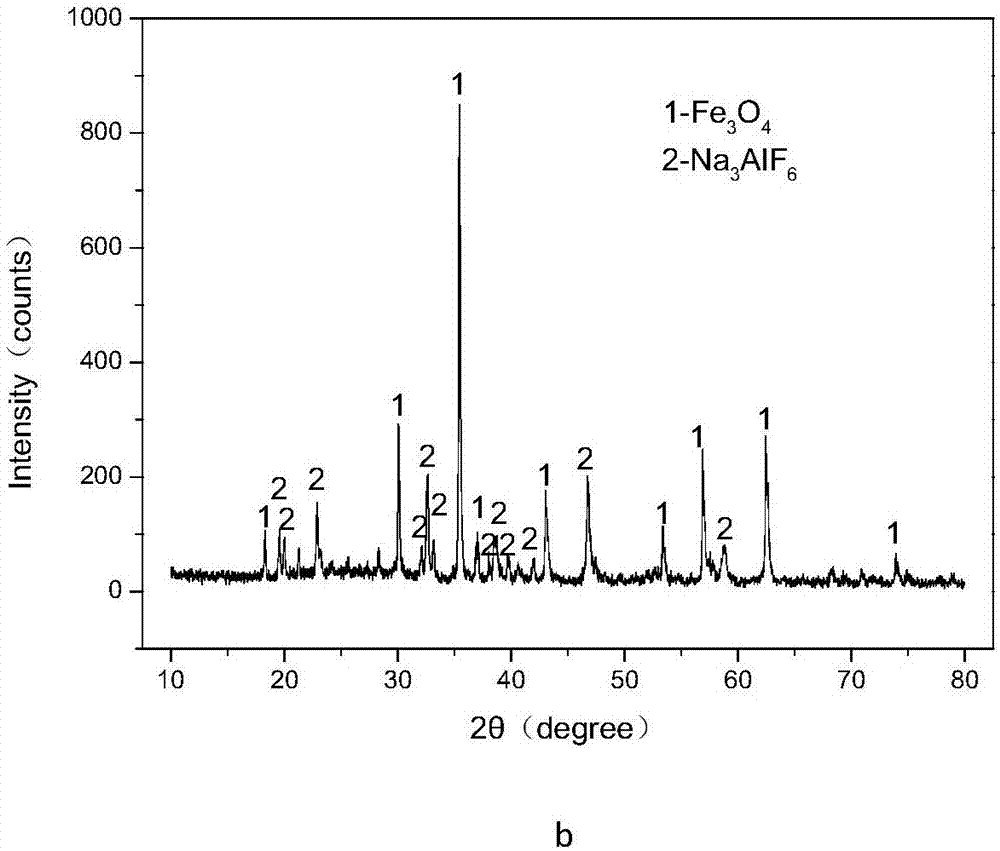

[0023] Sodium fluoroaluminate and copper slag are weighed according to the mass ratio of 1:1, and put into a star-shaped ball mill. The ball milling time is 2 hours, and the speed is 400r / min. The ball mill mixture is loaded into the atmosphere tube furnace. Air is blown in by a blower, high-temperature solid-state reaction is carried out at 1050°C for 60 minutes, and vibration milling is carried out after cooling, stirred and dissolved in hot water at 60°C for 100 minutes, and then separated by magnetic separation. The obtained product is magnetite and copper slag magnetic separation The rate is 90%, and the recovery rate of iron in slag is 96%.

Embodiment 2

[0025] The sodium fluoroaluminate and copper slag are weighed according to the mass ratio of 4:1, and put into a star ball mill. The ball milling time is 2h, and the speed is 400r / min. The ball mill mixture is put into the atmosphere tube furnace. Air is blown in by a blower, high-temperature solid-state reaction is carried out at 1010°C for 10 minutes, and vibration milling is carried out after cooling, stirred and dissolved in hot water at 60°C for 100 minutes, and then separated by magnetic separation. The obtained product is magnetite and copper slag magnetic separation The rate is 86%, and the recovery rate of iron in slag is 89.3%.

Embodiment 3

[0027] The sodium fluoroaluminate and copper slag are weighed according to the mass ratio of 3:1, and put into a star ball mill. The ball milling time is 2 hours, and the speed is 400r / min. The ball mill mixture is put into the atmosphere tube furnace. Air is blown in by the blower, high-temperature solid-state reaction is carried out at 1020°C for 40 minutes, and vibration milling is carried out after cooling, stirred and dissolved in hot water at 60°C for 100 minutes, and then separated by magnetic separation. The obtained product is magnetite and copper slag magnetic separation The rate is 89%, and the recovery rate of iron in slag is 93.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com