A prefabricated eps module wall and its construction method

A prefabricated, wall technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of slow construction, poor thermal insulation effect, heavy weight of prefabricated components, etc., and achieves low labor intensity, light weight, and fast construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

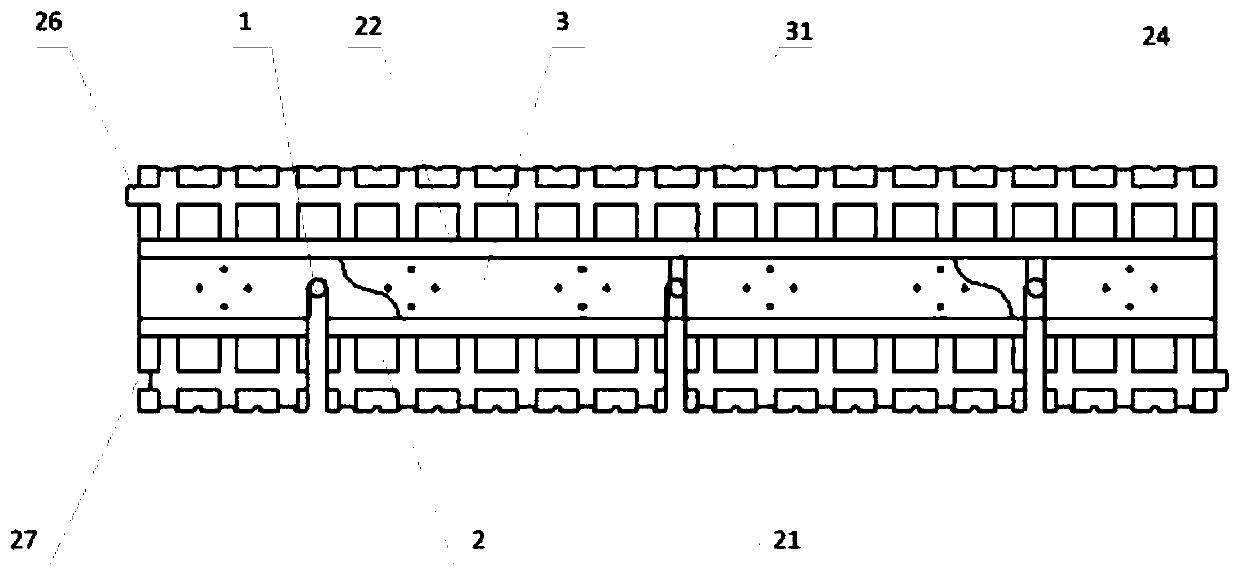

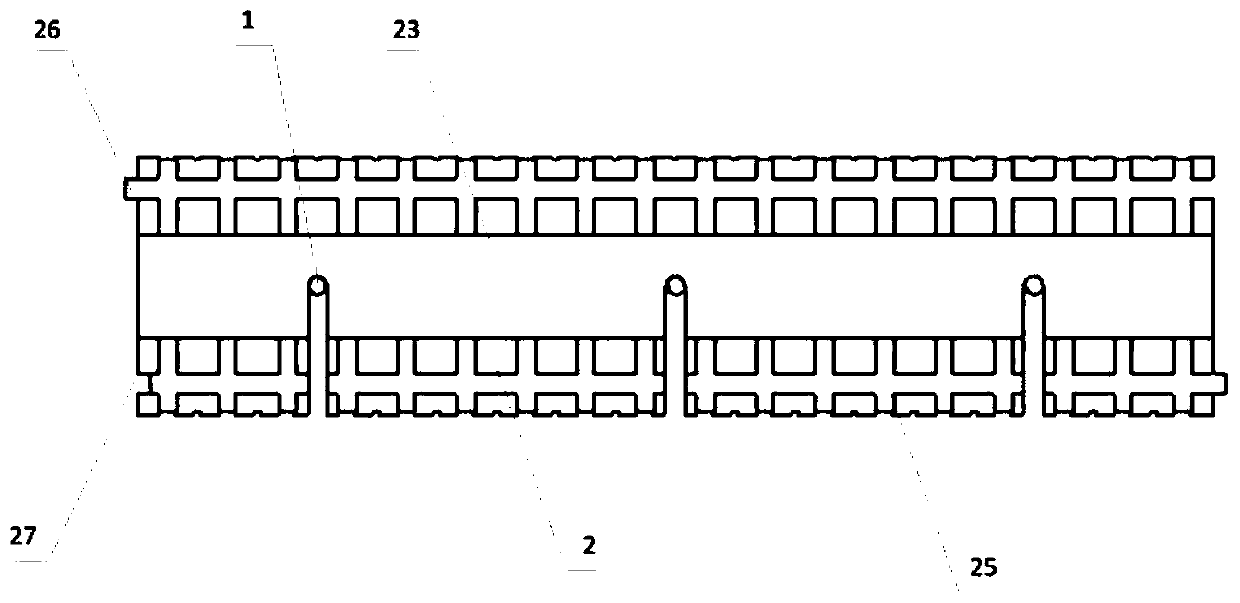

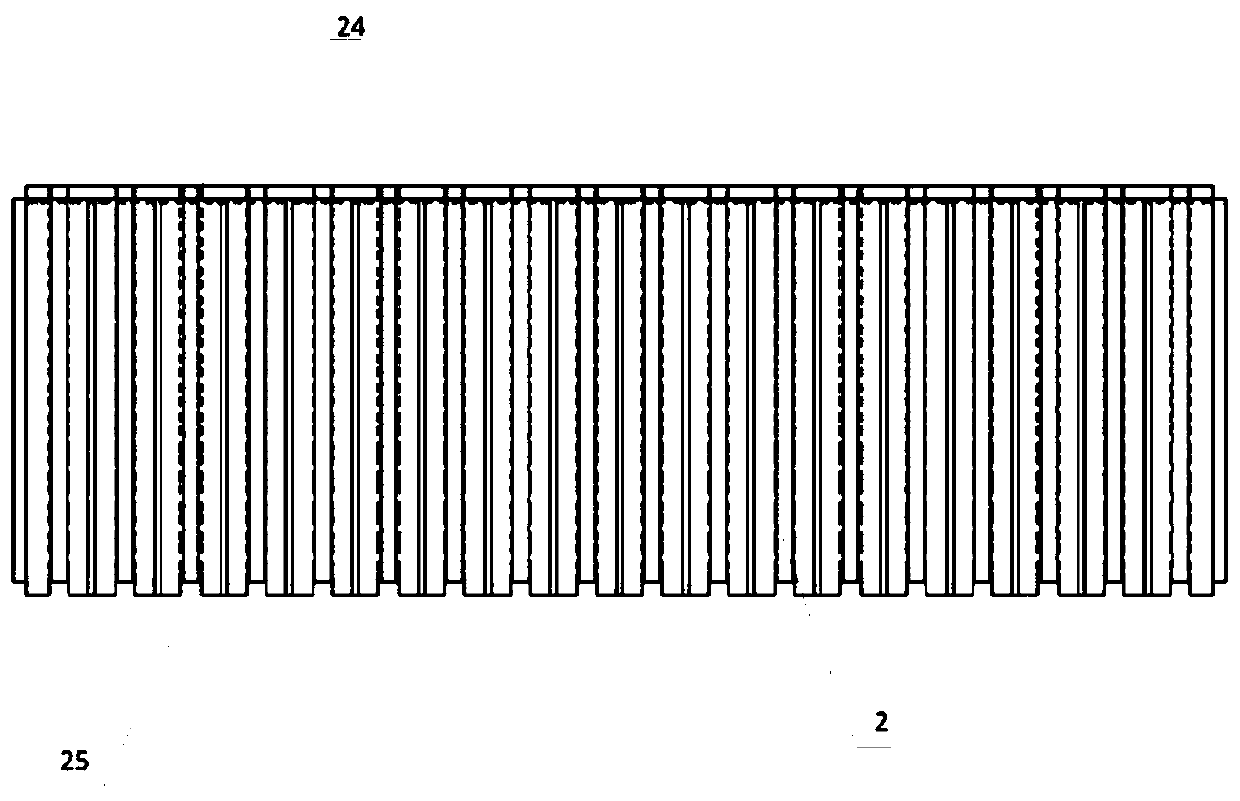

[0048] Such as Figure 1-4 As shown, the prefabricated EPS module wall provided in the first embodiment includes a fixed vertical bar 1 and an EPS module 2, wherein the fixed vertical bar 1 is perpendicular to the ground, and the bottom is fixed in the concrete foundation; the EPS module 2 is provided with There is a U-shaped groove 21 penetrating up and down, and the EPS module 2 is sleeved on the fixed vertical rib 1 through the U-shaped groove 21, and the U-shaped groove 21 matches the fixed vertical rib 1; the two sets of EPS modules 2 assembled up and down The opening direction of the U-shaped groove 21 is opposite; a positioning groove 22 is provided in the middle of the top of the EPS module 2 , and a positioning protrusion 23 is provided at the bottom.

[0049] The fixed vertical rib 1 can be a steel bar to securely fix the EPS module 2 . This embodiment one is suitable for relatively low-height self-built houses or villas, only relying on the engagement of the positi...

Embodiment 2

[0061] Another prefabricated EPS module wall provided in the second embodiment, in addition to the components provided in the first embodiment, also includes a sheet clamp 3, such as Figure 5 As shown, the sheet fixture 3 is provided with a U-shaped slot 31 that penetrates up and down, and the sheet fixture 3 is located between the positioning groove 22 of the EPS module 2 below it and the positioning protrusion 23 of the EPS module 2 above. , the U-shaped slot 31 is matched with the fixed rib 1, and the sheet clamp 3 is matched with the positioning groove 22 and the positioning protrusion 23.

[0062] The sheet fixture 3 can be a steel sheet fixture. The sheet fixture 3 and the above-mentioned fixed vertical rib 1 form a steel network that criss-crosses in the vertical direction, and the EPS module 2 is firmly fixed on the steel network. Among them, the mechanical strength of the final prefabricated EPS module wall is greatly improved, so that another prefabricated EPS modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com