Method for producing organic grape fruit wine without sulfur dioxide

A technology of grape fruit wine and production methods, applied in the direction of wine preparation, microbiological-based methods, biochemical equipment and methods, etc., which can solve the problems that wine cannot satisfy contemporary young people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

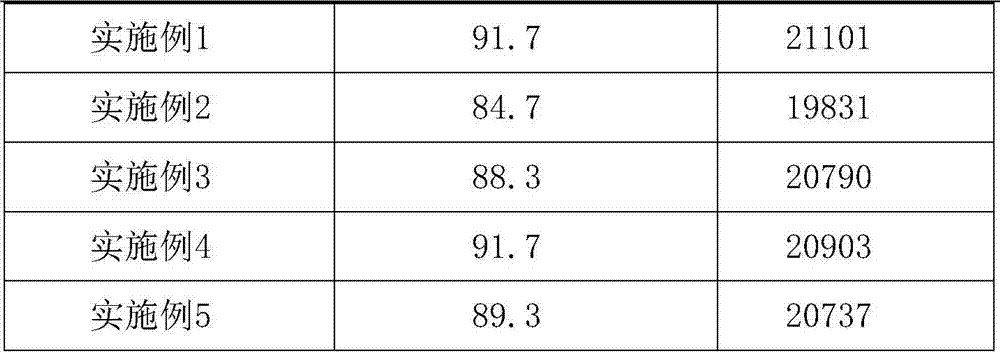

Embodiment 1

[0080] Interplant the geraniums in the orchard, manage the orchard in accordance with the organic planting requirements, pick the ripe fruits in the orchard to prepare juice, pick the mature grapes in the orchard to make wine, and mix the juice and wine according to the mass ratio of 5:95 to obtain organic grape wine;

[0081] The juice preparation is carried out according to the following steps:

[0082] 1) Harvesting: Fresh, healthy, disease-free fruits are harvested from organic orchards;

[0083] 2) Cooling: Reduce the temperature of the harvested fruits to 3°C;

[0084] 3) Fruit pulp enzyme inactivation: the fruit is de-stemmed and crushed to obtain fruit pulp. The fruit pulp is heated to 60°C for 30 minutes to inactivate the oxidase in the pulp, and the temperature is lowered to 18°C and transported to the fermentation tank;

[0085] 4) Clarification: Add enzyme in the fermenter, the enzyme dosage is 20-50mg / L, the temperature is 5-8℃, add clarifying agent, stand for precipitati...

Embodiment 2

[0131] Interplant the geraniums in the orchard, manage the orchard in accordance with the organic planting requirements, pick the ripe fruits in the orchard to prepare juice, pick the ripe grapes in the orchard to make wine, and mix the juice and wine according to the mass ratio of 10:90 to obtain organic grape wine;

[0132] The juice preparation is carried out according to the following steps:

[0133] 1) Harvesting: Fresh, healthy, disease-free fruits are harvested from organic orchards;

[0134] 2) Cooling: reduce the temperature of the harvested grapes to 3°C;

[0135] 3) Enzyme inactivation of fruit pulp: the fruit is de-stemmed and broken to obtain fruit pulp. The fruit pulp is heated to 60°C and kept for 30 minutes to inactivate the oxidase in the pulp, and the temperature is reduced to 18°C and transported to the fermentation tank;

[0136] 4) Clarification: Add enzyme in the fermenter, the amount of enzyme is 20-50mg / L, the temperature is 5-8℃, add clarifying agent, stand fo...

Embodiment 3

[0182] Interplant the geraniums in the orchard, manage the orchard in accordance with the organic planting requirements, pick the mature fruit in the orchard to prepare juice, pick the mature grapes in the orchard to make wine, and mix the juice and wine according to the quality ratio of 15:85 to obtain organic grape wine;

[0183] The juice preparation is carried out according to the following steps:

[0184] 1) Harvesting: Fresh, healthy, disease-free fruits are harvested from organic orchards;

[0185] 2) Cooling down: reduce the temperature of the harvested grapes to 3°C;

[0186] 3) Fruit pulp enzyme inactivation: the fruit is de-stemmed and crushed to obtain fruit pulp. The fruit pulp is heated to 60°C for 30 minutes to inactivate the oxidase in the pulp, and the temperature is lowered to 18°C and transported to the fermentation tank;

[0187] 4) Clarification: Add enzyme in the fermenter, the enzyme dosage is 20-50mg / L, the temperature is 5-8℃, add clarifying agent, stand for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com