A kind of composite nanofiber and preparation method thereof

A composite nanofiber and solution technology, applied in the field of nanomaterials, can solve the problems of high preparation and storage costs, complicated storage process, poor dispersion, etc., and achieve the effect of simple preparation process, low preparation cost and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

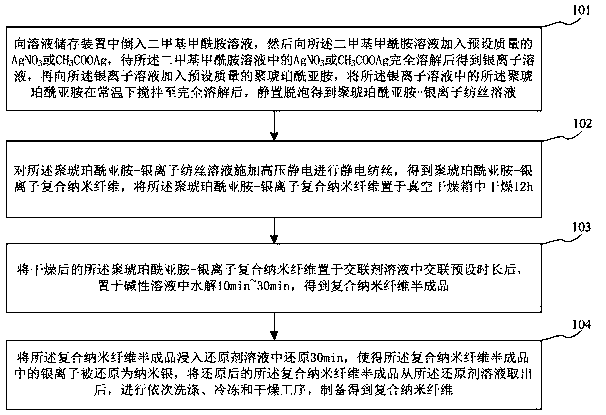

[0024] figure 1 It is a method flowchart of a method for preparing a composite nanofiber shown according to an exemplary embodiment, such as figure 1 As shown, the method includes:

[0025] Step 101, pour the dimethylformamide solution into the solution storage device, and then add a preset quality of AgNO to the dimethylformamide solution 3 or CH 3 COOAg, to be AgNO in the dimethylformamide solution 3 or CH 3 COOAg is completely dissolved to obtain a silver ion solution, then add polysuccinimide of a preset quality to the silver ion solution, and stir the polysuccinimide in the silver ion solution until completely dissolved at room temperature , standing for defoaming to obtain polysuccinimide-silver ion spinning solution.

[0026] Polysuccinimide is an intermediate of polyaspartic acid, and the molecular weight of polysuccinimide is 31500.

[0027] It should be noted that the solution storage device may be a beaker or a flask.

[0028] Step 102, applying high-voltage ...

Embodiment 2

[0039] (1) Pour dimethylformamide solution into the solution storage device, and then add CH to the dimethylformamide solution 3 COOAg, to be CH in the dimethylformamide solution 3 COOAg is completely dissolved to obtain a silver ion solution, and then polysuccinimide is added to the silver ion solution, and the polysuccinimide in the silver ion solution is stirred at normal temperature until it is completely dissolved, and then left standing to remove Bubble obtains polysuccinimide-silver ion spinning solution, in polysuccinimide-silver ion spinning solution, the mass percentage concentration of described polysuccinimide is 30%, CH 3 The content of COOAg is 1% of the mass of polysuccinimide.

[0040] Polysuccinimide is an intermediate of polyaspartic acid, and the molecular weight of polysuccinimide is 31500.

[0041] It should be noted that the solution storage device may be a beaker or a flask.

[0042] (2) Apply high-voltage static electricity to the polysuccinimide-sil...

Embodiment 3

[0048] (1) Pour the dimethylformamide solution into the solution storage device, and then add AgNO to the dimethylformamide solution 3 , to be the AgNO in the dimethylformamide solution 3 After completely dissolving, silver ion solution is obtained, then polysuccinimide is added to the silver ion solution, and the polysuccinimide in the silver ion solution is stirred at normal temperature until completely dissolved, then left standing for defoaming Obtain polysuccinimide-silver ion spinning solution, in polysuccinimide-silver ion spinning solution, the mass percentage concentration of described polysuccinimide is 34%, AgNO 3 The content is 20% of the mass of polysuccinimide.

[0049] Polysuccinimide is an intermediate of polyaspartic acid, and the molecular weight of polysuccinimide is 31500.

[0050] It should be noted that the solution storage device may be a beaker or a flask.

[0051] (2) Apply high-voltage static electricity to the polysuccinimide-silver ion spinning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com