Method of producing original-color paper pulp through low-alkali cooking

An alkaline cooking and natural color technology, applied in the direction of digester, pulping with inorganic alkali, papermaking, etc., can solve the problems of increased acid addition adjustment cost, difficult treatment of polluted white mud, high cost of sewage treatment, and reduced recovery costs and Processing difficulty, saving pulp cost, and reducing the effect of alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is illustrated with examples below, and it should be understood that the examples are used to illustrate the present invention rather than limit the present invention. The scope and essential content of the present invention are defined by the claims.

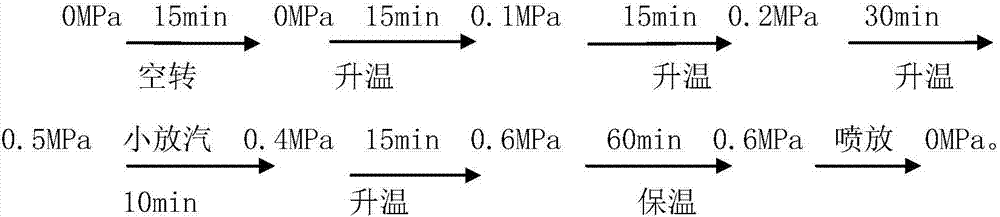

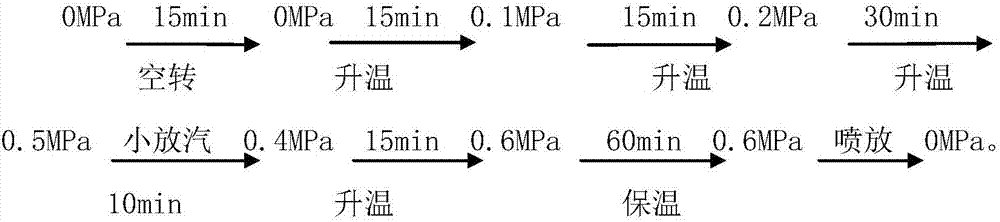

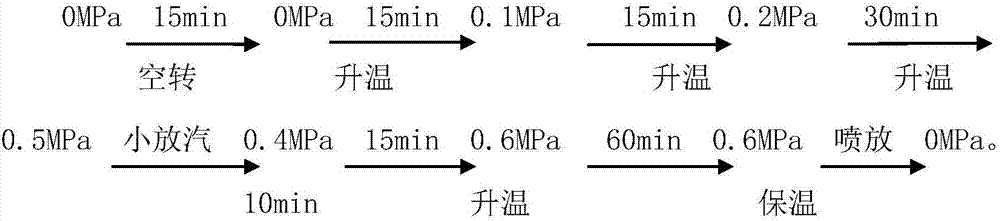

[0032] Process flow of the present invention:

[0033] Wheat straw—roller mower—dust collector—drum washer—hydraulic grass washer—oblique spiral grass squeezer—belt conveyor—presoaker—steamer ball—spray bin—single screw squeezer—underground storage Pulp tank - pulp tank before washing - 2m 2 Skip sieve - deflagging machine - 4 sets of series planar valve drum type vacuum pulp washing unit - outflow pressure screen - pulp washing machine - secondary purification system - oxygen delignification - pulp washing machine - pulp storage tank (for use in papermaking workshop ).

[0034] The specific process includes the following:

[0035] 1. Wet preparation

[0036] Stack the purchased wheat straw int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| beating degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com