Method and apparatus for testing fracture toughness of pipeline steel in hydrogen-containing synthetic natural gas environment

A coal-to-natural gas and fracture toughness technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to respond to service conditions, waste of pipeline steel performance, and fast hydrogen diffusion, and achieve accurate and accurate experimental results. Reliable, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

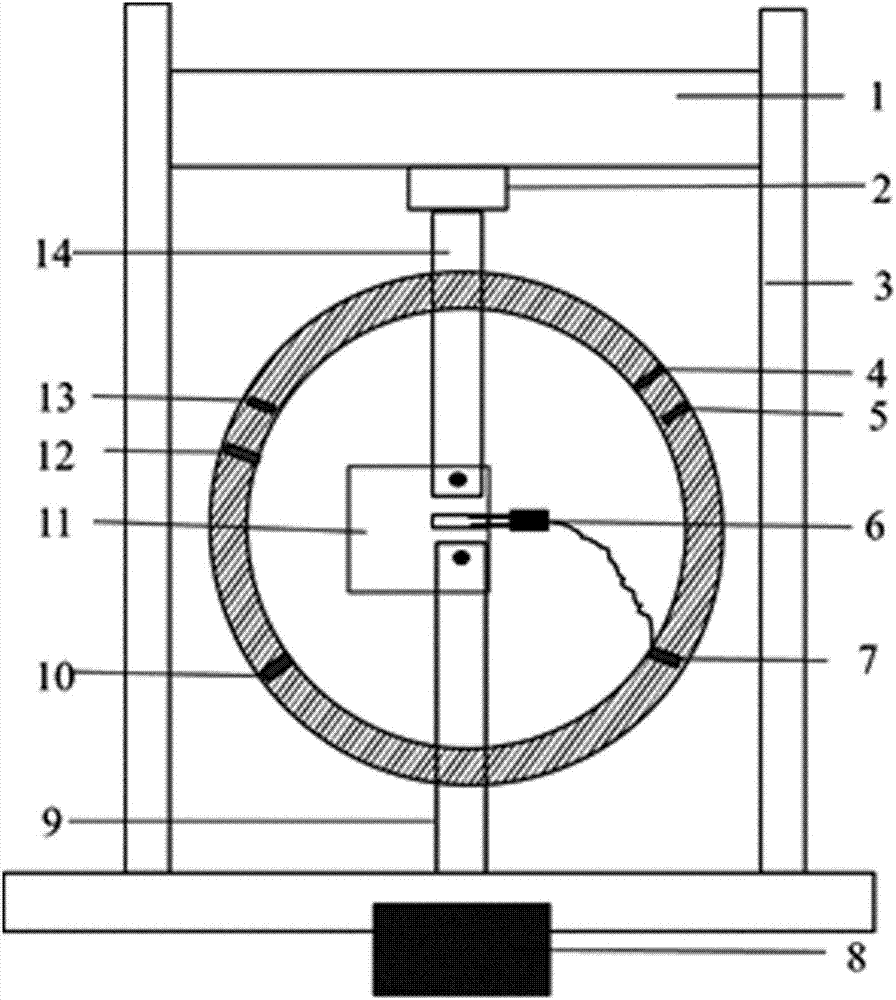

[0053] This embodiment provides a test device for the fracture toughness of pipeline steel in the hydrogen-containing coal-to-natural gas environment, and its structure is as follows figure 1 As shown, the test device includes: test equipment and environmental chamber;

[0054] Wherein, the test equipment includes a fatigue testing machine 1 and an extensometer test assembly;

[0055] The environmental box is provided with an air inlet connection port 4, a pressure gauge connection port 5, an extensometer connection port 7, a vacuum pump connection port 10, a first gas outlet 12 and a second gas outlet 13;

[0056] The main material of the environmental chamber of the environmental chamber is 316L, which is fixed in the fatigue testing machine 1, and the fatigue testing machine is fixed on the testing machine frame 3;

[0057] The crack opening displacement extensometer 6 is arranged inside the environmental box, and the signal of the crack opening displacement extensometer 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com