Manual ultrasonic visual nondestructive detection device and method based on camera shooting positioning

A technology of non-destructive testing and detection devices, which is applied in the direction of measuring devices, processing detection response signals, and optical testing of flaws/defects. It can solve problems such as inability to detect on-site, large sensitivity loss, and inability to be portable, and achieve correction of color deviations in color codes. , Improve processing speed, and fast and accurate search effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

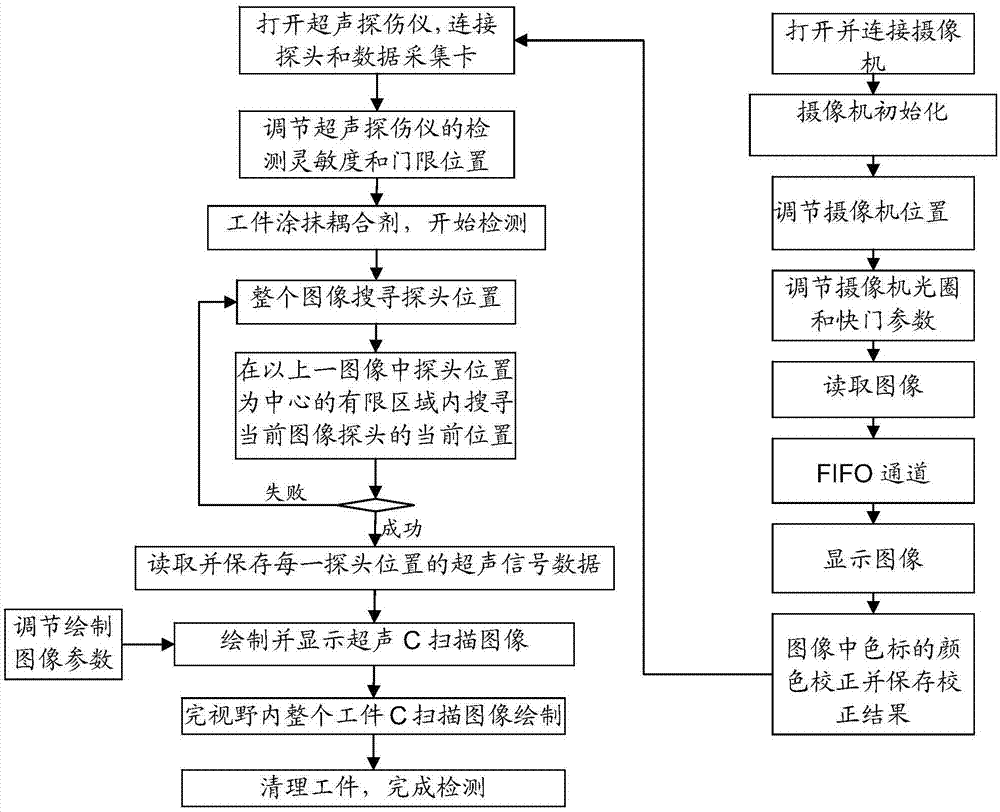

[0047] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

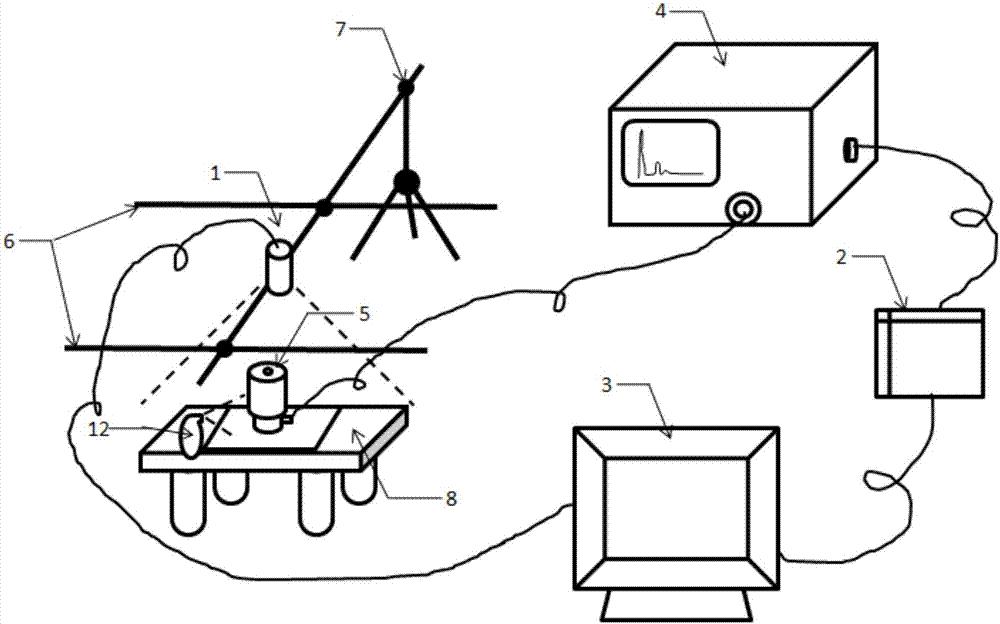

[0048] Such as figure 1 , 2 As shown, the present invention proposes an ultrasonic visualization nondestructive testing device based on camera positioning, including: camera 1, data acquisition card 2, industrial computer 3, ultrasonic flaw detector 4, detection device 5, stable light source 6, bracket 7 and working The stage 8 also includes a coupling device 12 for spraying a coupling agent on the surface of the object to be tested.

[0049] Camera 1: The full frame rate of the camera is required to be greater than 150 frames / s, the resolution greater than 1 million pixels, and the frame can be changed arbitrarily;

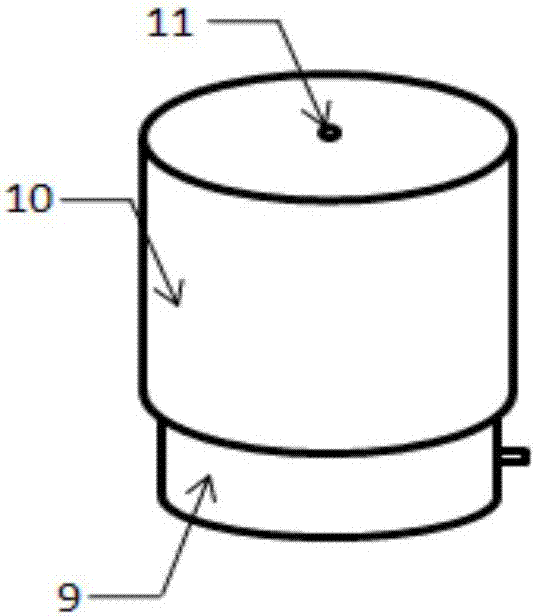

[0050] Ultrasonic flaw detector 4: generate electrical oscillation and apply it to the probe 9, excite the probe to generate ultrasonic waves, and after the ultrasonic waves propagate inside the inspected part, the probe receives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com