Copper rotor

A technology of rotor and copper casting, which is applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of large starting current, small starting torque, and exceeding the tolerance range, so as to achieve the reduction of rotor resistance, Reduced heat loss and low inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

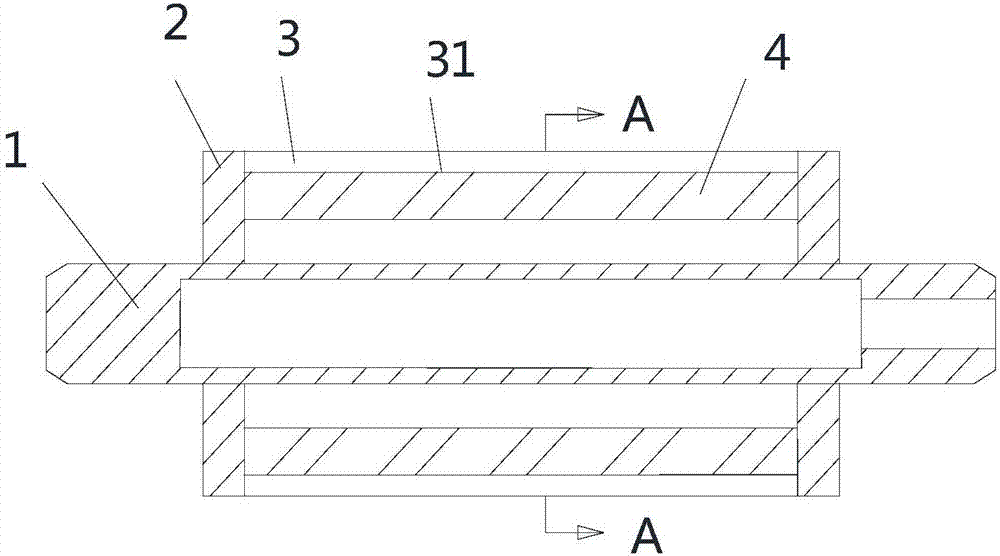

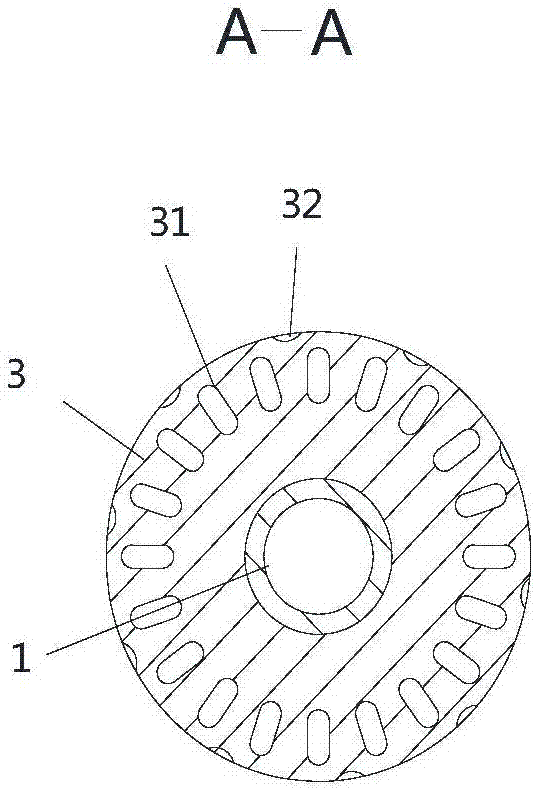

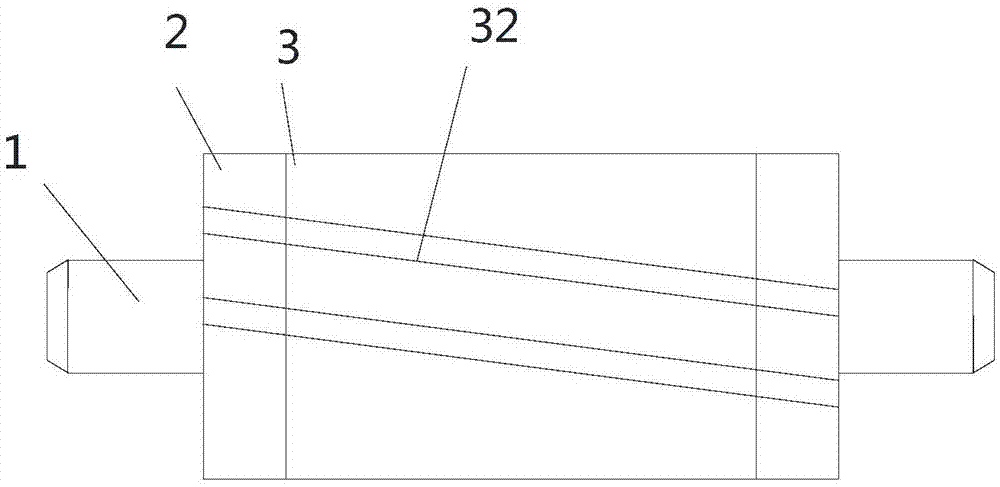

[0020] Such as Figure 1 to Figure 3 As shown, the cast copper rotor includes a silicon steel sheet body 3 obtained by stacking silicon steel sheets, and also includes a rotating shaft 1 embedded in the hole 3 of the silicon steel sheet body for carrying the silicon steel sheet body. Several pouring holes 31 are evenly distributed along the circumferential direction, copper end caps 2 are poured and formed at both ends of the silicon steel sheet body 3, and copper conductors 4 connected to the copper end caps are formed in the pouring holes 31. The rotating shaft 1 is Hollow shaft.

[0021] The present invention designs a cast copper rotor processed by die-casting, which uses the excellent electrical conductivity of copper to reduce rotor loss, improve point activation efficiency, and reduce rotor resistance, which means that under the same to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com