Propulsion type reaction device and culture method for culturing of aerobic granular sludge

An aerobic granular sludge and reaction device technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of complex structure, increased system operation cost and high construction cost, Achieve the effect of overcoming complex operation and operation, wide production adaptability and simple structure setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure and cultivation method of a propulsion reactor for cultivating aerobic granular sludge provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

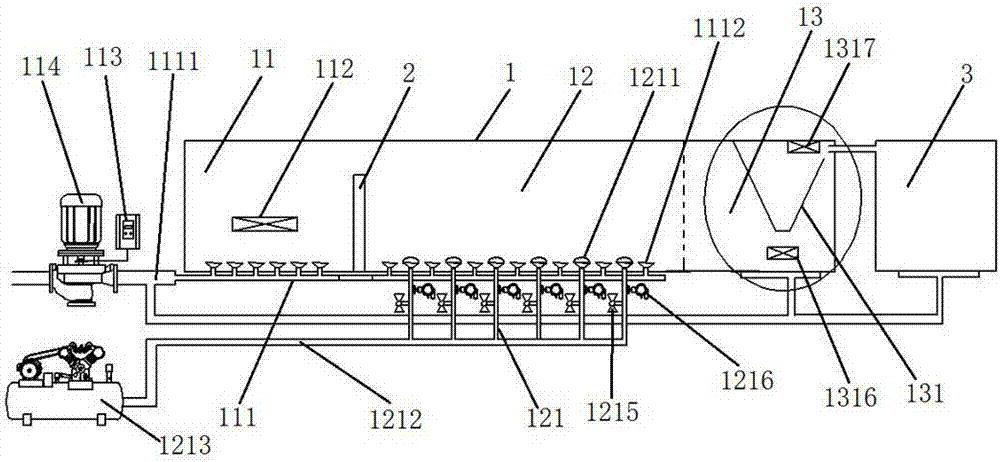

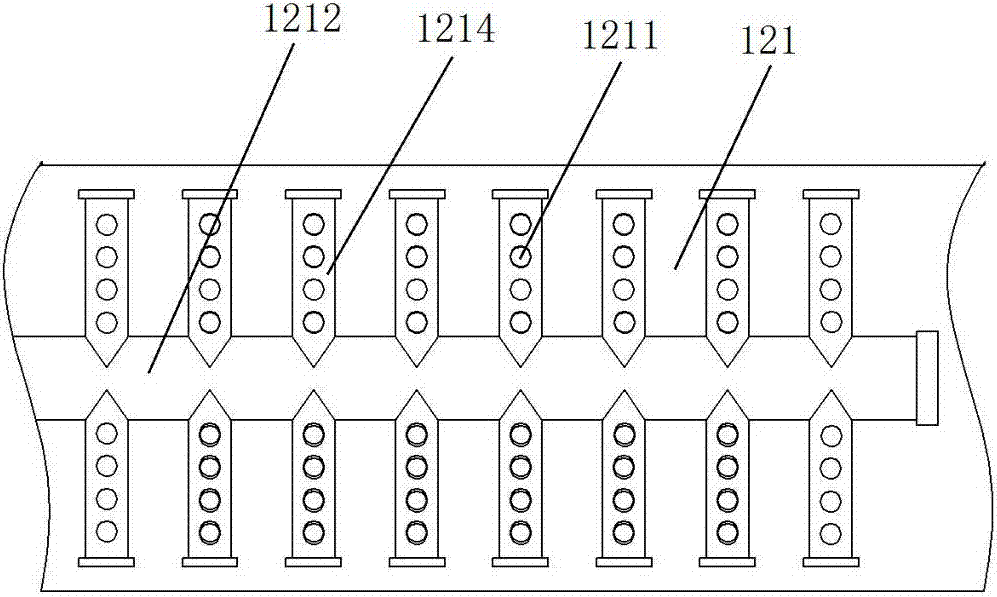

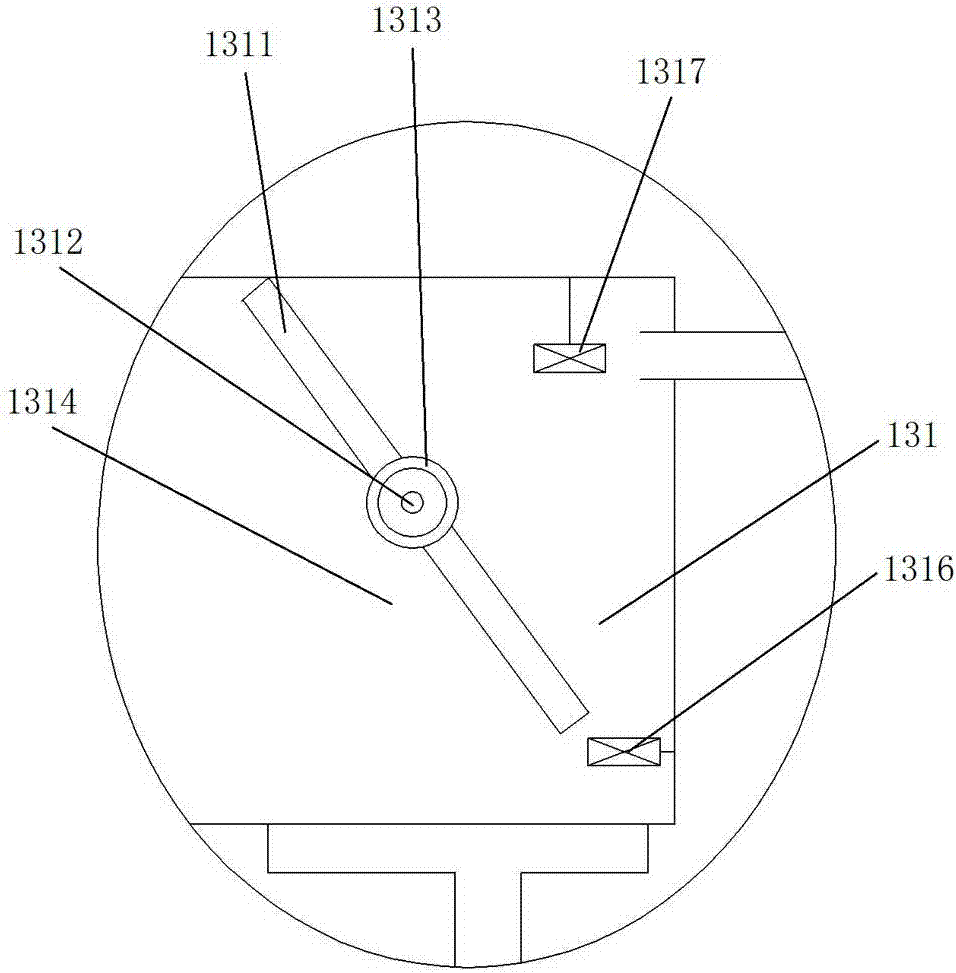

[0035] Such as figure 1Shown is a schematic structural diagram of a propulsion reaction device A for cultivating aerobic granular sludge provided by the present invention. The interior of the reaction vessel 1 constituting the propulsion reaction device is composed of a sedimentation zone 11, a progressive aeration zone 12 and an aerobic granular sludge separation zone 13 in sequence according to the direction of reaction propulsion, wherein the bottom of the sedimentation zone 11 is provided with a The water distribution system 111, the progressive aeration zone 12 and the sedimentation zone 11 have a partition baffle 2, and the sludge formed in the sedimentation zone 11 crosses the partition baffle 2 along with the water flow; a progressive aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com