Nano-porous copper oxide/copper oxide nanowire composite structure and preparation method thereof

A technology of copper oxide nanowires and nanoporous copper, which is applied in the field of semiconductor nano-metal oxide preparation, can solve the problems of complex preparation process and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Pre-set the heating temperature on the heating platform to 250°C, and after the heating platform rises from room temperature to 250°C in the air, immediately place nanoporous copper (specific surface area 3.0㎡ / g) on the heating platform for 1 hour and then naturally Cool to room temperature to make copper oxide nanowires grow in the pore wall of nanoporous copper oxide, that is, nanoporous copper oxide / copper oxide nanowire composite structure, the specific surface area is 4.8㎡ / g, the diameter of the nanowire is 5-15nm, the length 20-200nm.

Embodiment 2

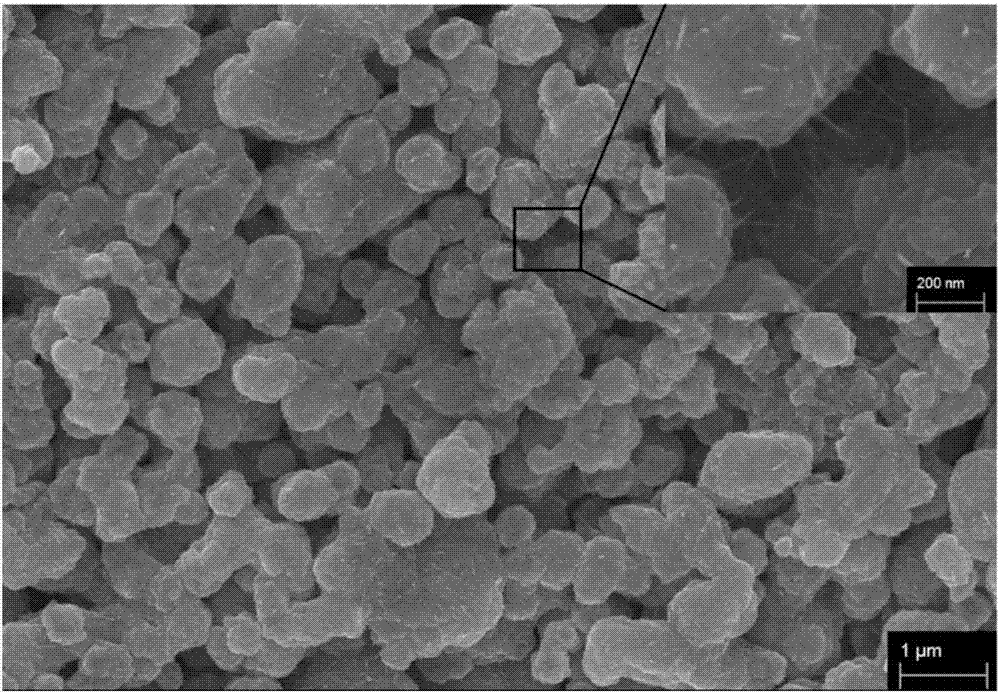

[0025] Pre-set the heating temperature on the heating platform as 260°C. After the heating platform rises from room temperature to 260°C in the air, immediately place nanoporous copper (specific surface area 3.0㎡ / g) on the heating platform for 1 hour and then naturally Cool to room temperature, make copper oxide nanowire grow in the pore wall of nanoporous copper oxide, obtain nanoporous copper oxide / copper oxide nanowire composite structure, see figure 1 , the specific surface area is 5.0㎡ / g, the nanowire diameter is 8-18nm, and the length is 70-250nm.

Embodiment 3

[0027] Preset the heating temperature on the heating platform to 270°C. After the heating platform rises from room temperature to 270°C in the air, immediately place nanoporous copper (specific surface area 3.0㎡ / g) on the heating platform for 1 hour and then naturally Cool to room temperature to make copper oxide nanowires grow in the pore wall of nanoporous copper oxide, and obtain nanoporous copper oxide / copper oxide nanowire composite structure, with a specific surface area of 4.9㎡ / g, a nanowire diameter of 8-18nm, and a length of 30-300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com