Multi-cold-source intelligent Baijiu brewing thermal environment control system

A control system and thermal environment technology, applied in the preparation of alcoholic beverages, industrial buildings, etc., can solve the problems of high system cost, high energy consumption in operation, and inability to accurately control the temperature of cellar pools, etc. Reduce and facilitate the effect of convection heat transfer and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

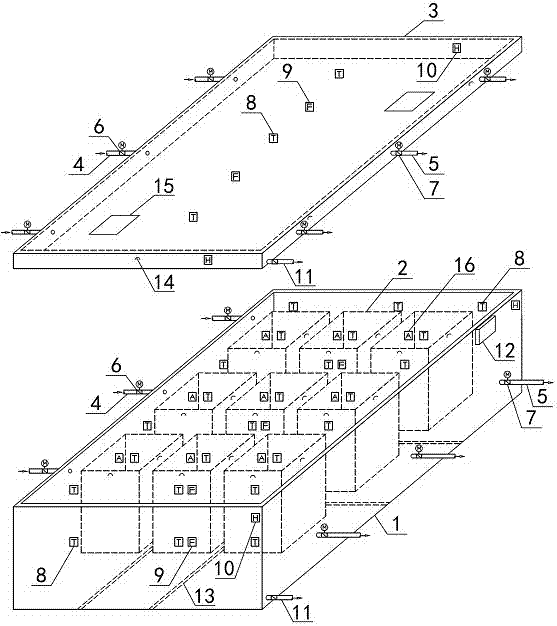

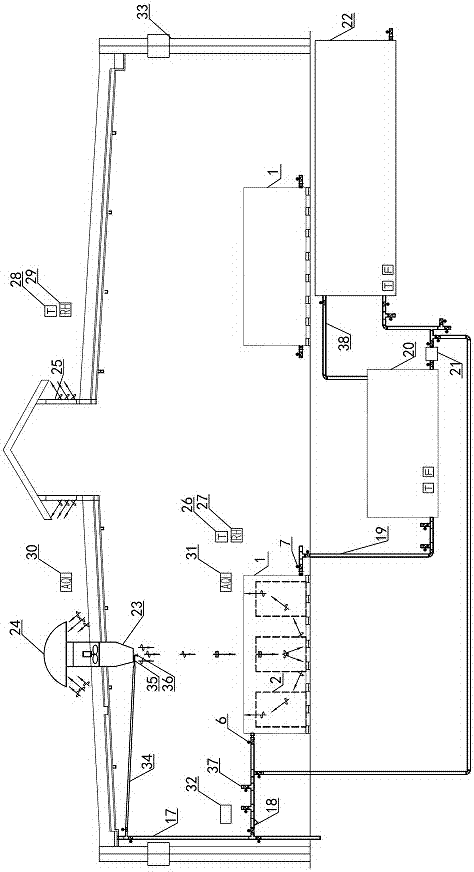

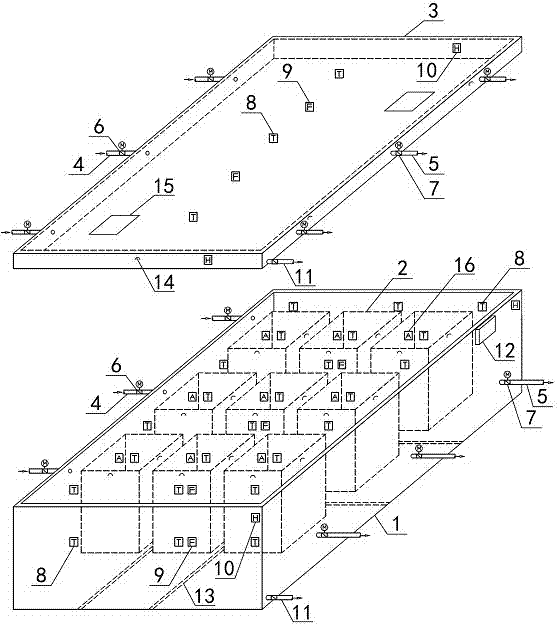

[0069] refer to figure 1 and figure 2 , a multi-cold source intelligent liquor brewing thermal environment control system, including a convection heat exchange cellar 1, a built-in fermentation tank 2, a convection heat exchange cover tank 3, a system controller I12, a rainwater collection pipe 17, and an underground turnover water tank 20 and Plant 33;

[0070] The convection heat exchange cellar 1 and the convection heat exchange cover plate groove 3 are provided with a water inlet pipe 4, an outlet pipe 5, an electric water inlet valve 6, and an electric water outlet valve 7, and the inner wall surface of the convection heat exchange cellar 1 , the inner wall of the built-in fermentation tank 2 and the convection heat exchange cover tank 3 are provided with temperature sensors 8, and the convection heat exchange pit tank 1 and the convection heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com