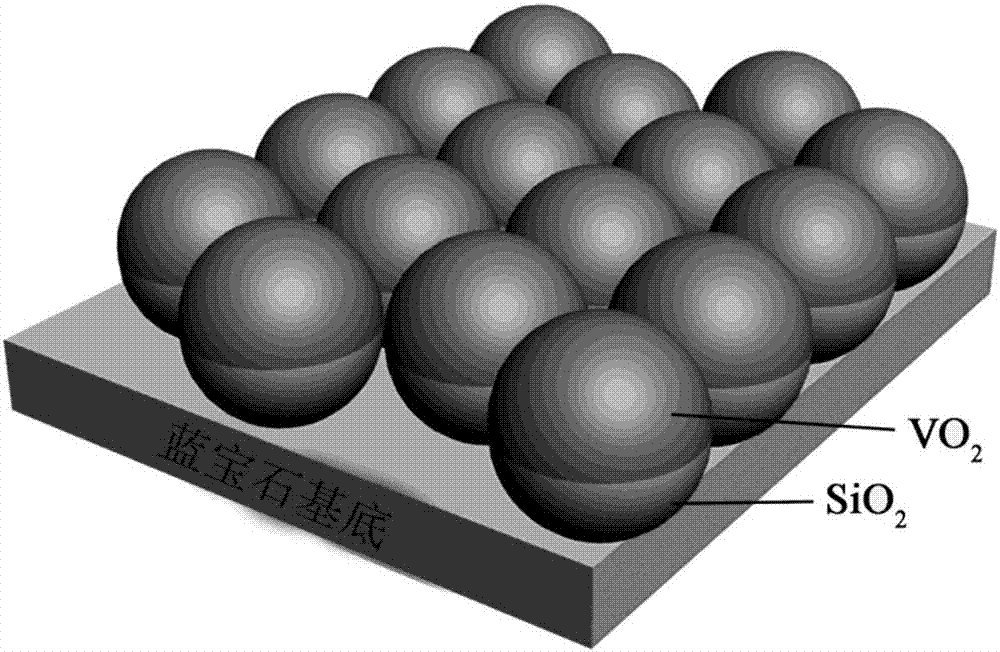

Preparation method of silicon dioxide nanosphere array-VO2 thin film composite structure

A silicon dioxide, -VO2 technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., to achieve large-area production, simple preparation process, and achieve the effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Substrate cleaning: The substrate used is a double-polished sapphire substrate with (001) crystal plane, 1×1cm 2 , with a thickness of 0.45mm; put the substrate into deionized water, acetone and absolute ethanol in order to ultrasonically clean it for 20 minutes respectively to remove organic impurities on the surface; after cleaning, put the substrate into absolute ethanol for later use.

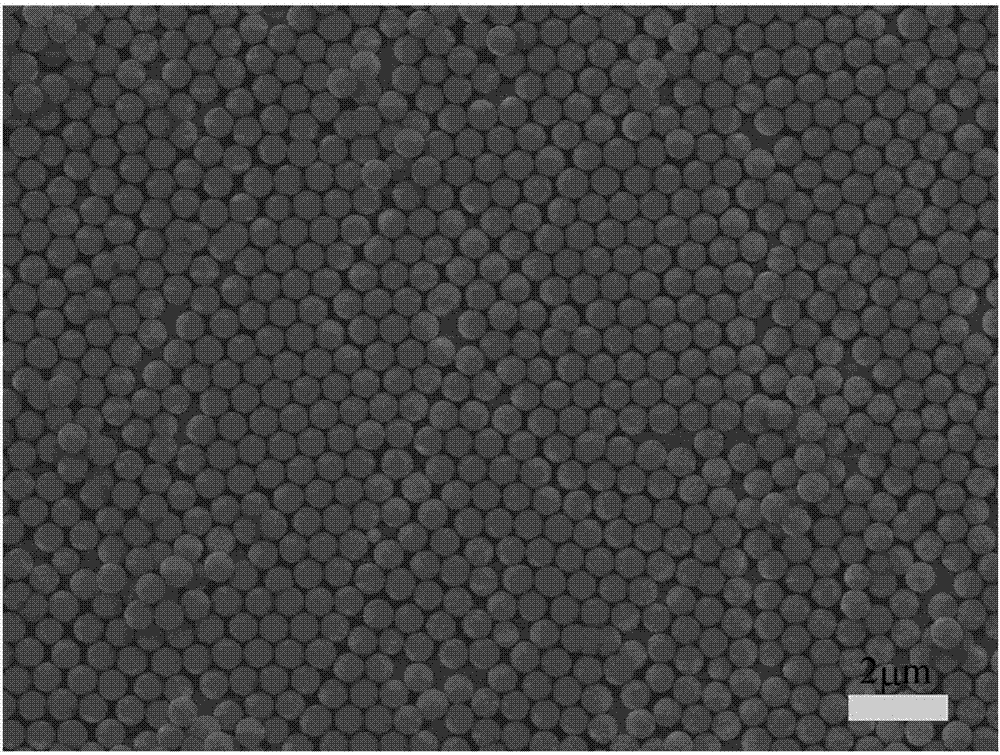

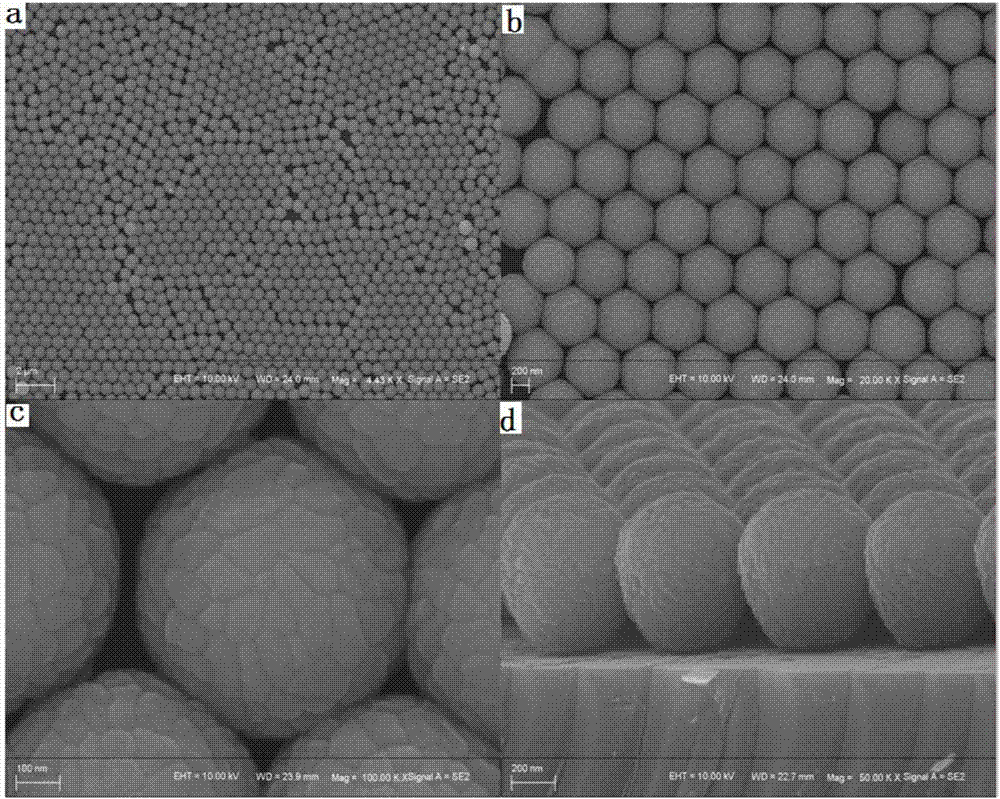

[0028] (2) Preparation of monodisperse SiO 2 mask layer:

[0029] First, insert the clean drainage sheet obliquely into a certain amount of deionized water, and then use a pipette gun to dissolve SiO with a particle size of 600nm 2 The ball solution is added dropwise to the drainage sheet, and it slowly flows to the water surface, and spreads evenly to form a high-density, large-area single-layer SiO 2 Array, thus formulated as a lifting solution. After standing still until the liquid level is stable, slowly fix the substrate with a coating puller and immerse it in the pulling...

Embodiment 2

[0038] (1) Substrate cleaning: The substrate used is a double-polished sapphire substrate with (001) crystal plane, 1×1cm 2 , with a thickness of 0.45mm; put the substrate into deionized water, acetone and absolute ethanol in order to ultrasonically clean it for 30 minutes, respectively, to remove organic impurities on the surface; after cleaning, put the substrate into absolute ethanol for later use.

[0039] (2) Preparation of monodisperse SiO 2 mask layer:

[0040] First, insert the clean drainage sheet obliquely into a certain amount of deionized water, and then use a pipette gun to dissolve SiO with a particle size of 600nm 2 The ball solution is added dropwise to the drainage sheet, and it slowly flows to the water surface, and spreads evenly to form a high-density, large-area single-layer SiO 2 Array, thus formulated as a lifting solution. After standing still until the liquid level is stable, slowly immerse the substrate in the pulling liquid with a coating pulling ma...

Embodiment 3

[0046] (1) Substrate cleaning: The substrate used is a double-polished sapphire substrate with (001) crystal plane, 1×1cm 2 , with a thickness of 0.4mm; put the substrate into deionized water, acetone and absolute ethanol in order to ultrasonically clean it for 30 minutes, respectively, to remove organic impurities on the surface; after cleaning, put the substrate into absolute ethanol for later use.

[0047] (2) Preparation of monodisperse SiO 2 mask layer:

[0048] First, insert the clean drainage sheet obliquely into a certain amount of deionized water, and then use a pipette gun to dissolve SiO with a particle size of 600nm 2 The ball solution is added dropwise to the drainage sheet, and it slowly flows to the water surface, and spreads evenly to form a high-density, large-area single-layer SiO 2 Array, thus formulated as a lifting solution. After standing still until the liquid level is stable, slowly immerse the substrate in the pulling liquid with a coating pulling m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com