Corn lamp made of SMD lamp beads and conductive lines bent

A technology of conductive lines and corn lamps, which is applied in the direction of circuit layout, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems that affect the popularization and use, and the cost of the whole lamp remains high, so as to reduce the production process and production Cost, precise assembly process, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

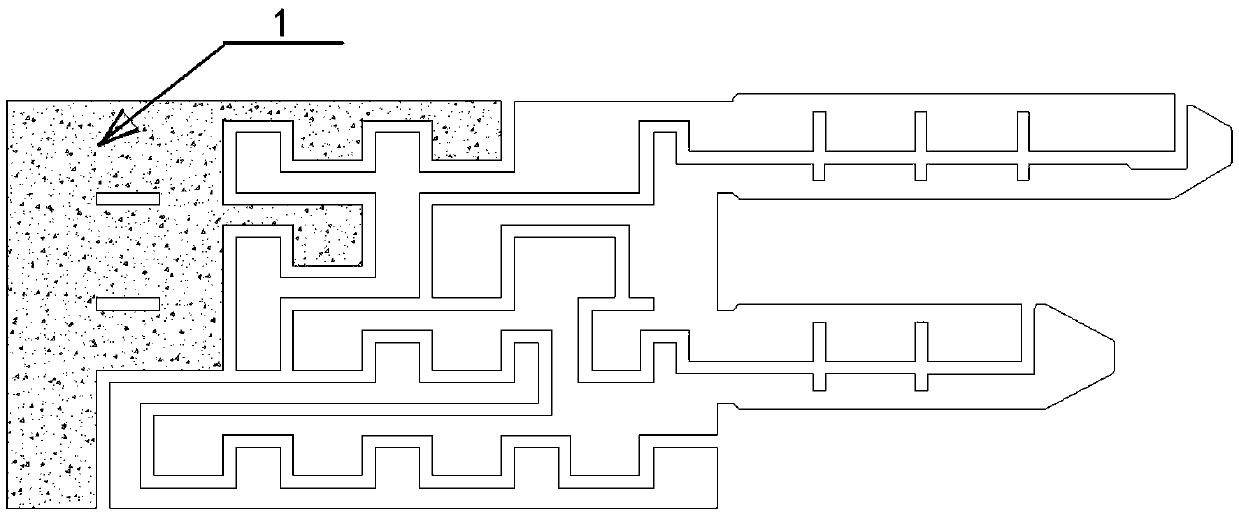

[0052] Choose a flat tinplate sheet with a thickness of 0.2, with a length and width of 170X85, and paint the solder mask oil 22 (solder mask screen) on the circuit diagram with white oil, such as Figure 16 , a circular pad 17 and a lamp bead pad 18 are arranged on it;

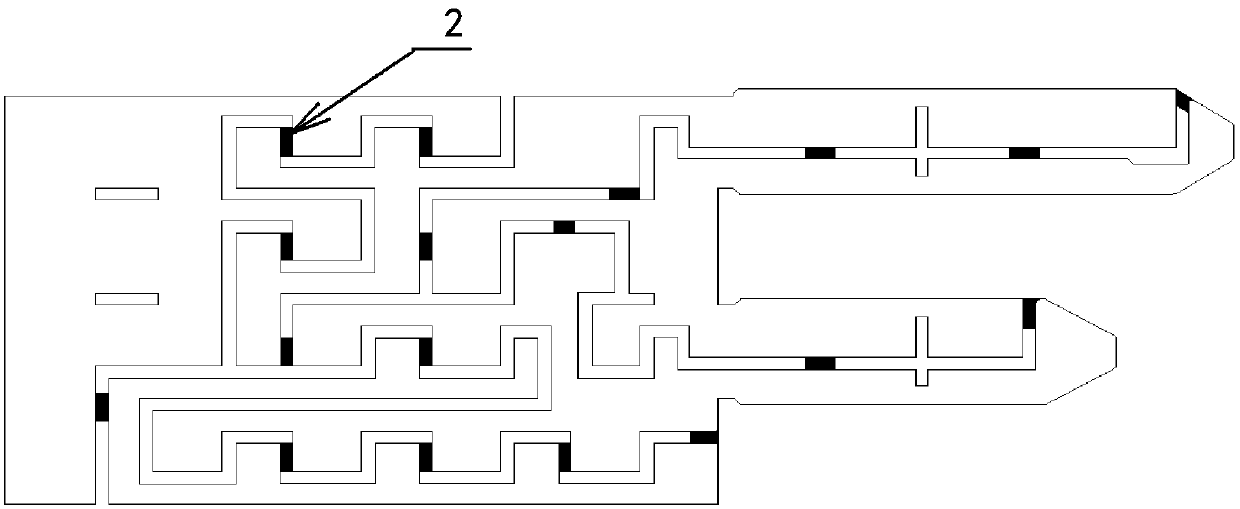

[0053] In the figure, the three circular pads in the lower left corner, lower right corner, and upper right corner are the positioning holes 19 of the punching machine. The positioning holes are drilled with a drill press, and the first punching is performed. After punching, the positioning ribs and bends are left on the board. Auxiliary tendons, such as Figure 17 ;

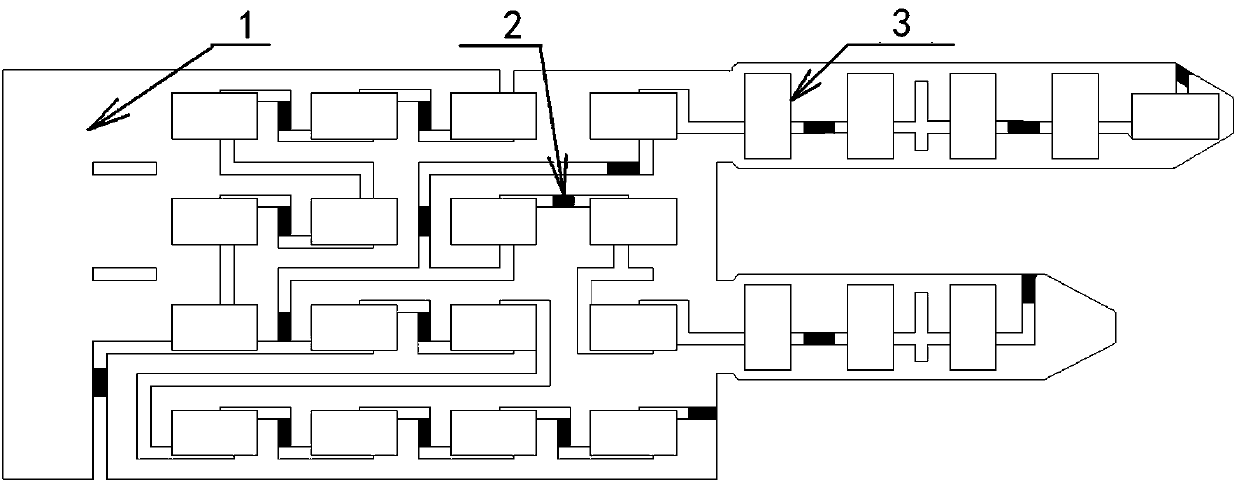

[0054] Brush the solder paste on the board that was punched out for the first time, paste the patch lamp beads (5630 lamp beads), go through reflow soldering, and then paste the insulating positioning block on the line isolator, such as Figure 18 ;

[0055] Perform the second punching, remove the positioning ribs, and retain the bending aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com