Pigment printing paste and protective agent for printing and hot stamping and printing and hot stamping process using it to prevent pigment printing from staining gold foil

A paint printing and protective agent technology, which is applied in the field of textile printing and dyeing, can solve the problems of unclear patterns on the surface of the fabric, staining, and the overall effect is disorderly, and achieve the effect of soft and full hand feeling and avoiding staining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

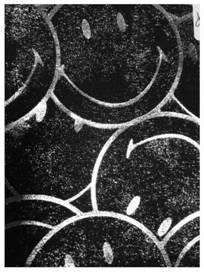

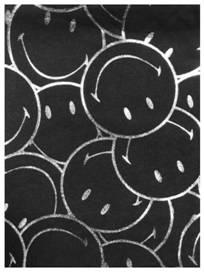

Image

Examples

Embodiment 1

[0059] Embodiment 1 (cotton / span weft knitted fabric)

[0060] A printing and hot stamping process for preventing pigment printed fabrics from being stained with gold foil during the hot stamping process, the steps are as follows:

[0061] (1) Deploying anti-staining pigment printing paste

[0062] The formula of anti-sticking pigment printing paste is as follows (by weight percentage):

[0063]

[0064] The parameters of anti-staining pigment printing paste are as follows:

[0065] Viscosity: 20000cps

[0066] pH value: 6-7

[0067] (2) Printing

[0068] Add the required paint color (0-6% by weight), use the printing screen made of 1350# and 800# mesh, and the scraper with 65H hardness. After scraping, carry out flat screen printing to make anti-stick Pigment printing paste and bronzing paste form a colored film pattern on the surface of the fabric.

[0069] (3) Baking

[0070] Use a width setting machine, add a protective agent, and bake at 150 degrees Celsius for ...

Embodiment 2

[0074] Embodiment 2 (cotton / span weft knitted fabric)

[0075] A printing and hot stamping process for preventing pigment printed fabrics from being stained with gold foil during the hot stamping process, the steps are as follows:

[0076] (1) Allocate anti-staining pigment printing paste (weight percentage meter)

[0077] The formula of anti-staining pigment printing paste is as follows:

[0078]

[0079] The parameters of anti-staining pigment printing paste are as follows:

[0080] Viscosity: 20000cps

[0081] pH value: 6-7

[0082] (2) Printing

[0083] Add the required paint color (0-6% by weight), use the printing screen made of 1350# and 800# mesh, and the scraper with 65H hardness. After scraping, carry out flat screen printing to make anti-stick Pigment printing paste and bronzing paste form a colored film pattern on the surface of the fabric.

[0084] (3) Baking

[0085] Use a width setting machine, add a protective agent, and bake at 150 degrees Celsius fo...

Embodiment 3

[0089] Embodiment 3 (cotton / span weft knitted fabric)

[0090] A printing and hot stamping process for preventing pigment printed fabrics from being stained with gold foil during the hot stamping process, the steps are as follows:

[0091] (1) Allocate anti-staining pigment printing paste (weight percentage meter)

[0092] The formula of anti-staining pigment printing paste is as follows:

[0093]

[0094]

[0095] The parameters of anti-staining pigment printing paste are as follows:

[0096] Viscosity: 20000cps

[0097] pH value: 6-7

[0098] (2) Printing

[0099] Add the required paint color (0-6% by weight), use the printing screen made of 1350# and 800# mesh, and the scraper with 65H hardness. After scraping, carry out flat screen printing to make anti-stick Pigment printing paste and bronzing paste form a colored film pattern on the surface of the fabric.

[0100] (3) Baking

[0101] Use a width setting machine, add protective agent, and bake at 150 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com