Arc self-bearing gutter

A self-supporting, arc-shaped technology, applied in roofing, roof drainage, construction, etc., can solve the problems of conventional gutters that do not take into account applicability, energy saving and environmental protection, economy and beauty, low comprehensive energy efficiency, gutter deformation, etc., to achieve a wide range Market application prospects, significant economic benefits, simple and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

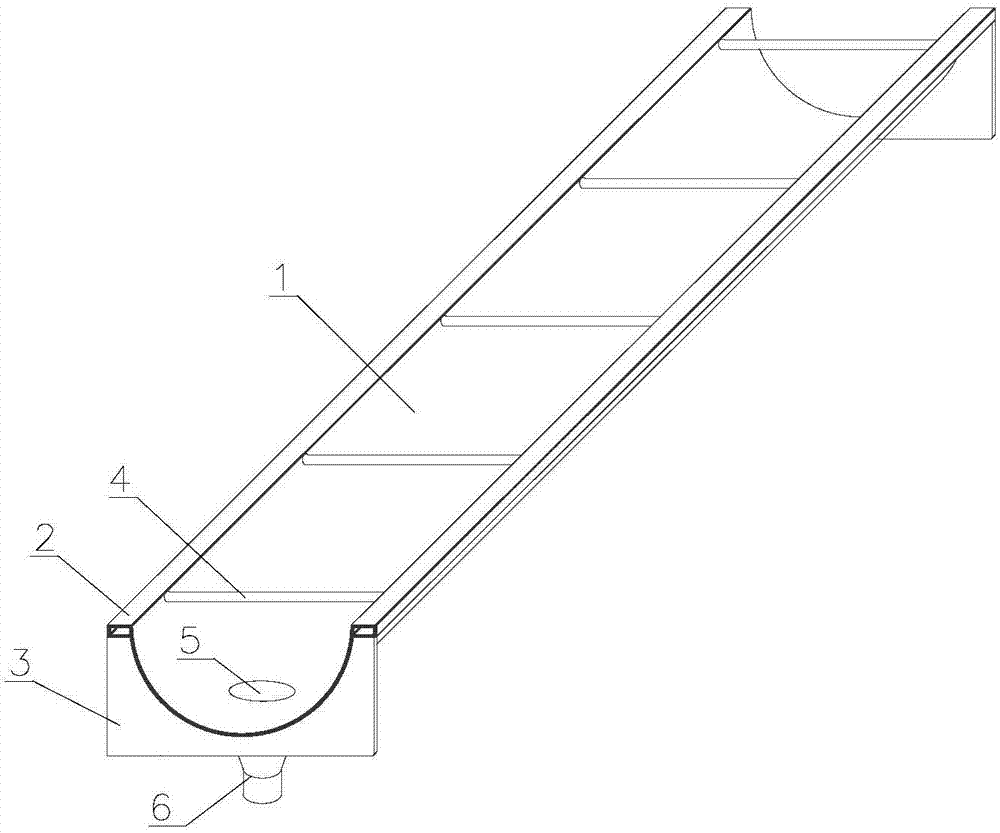

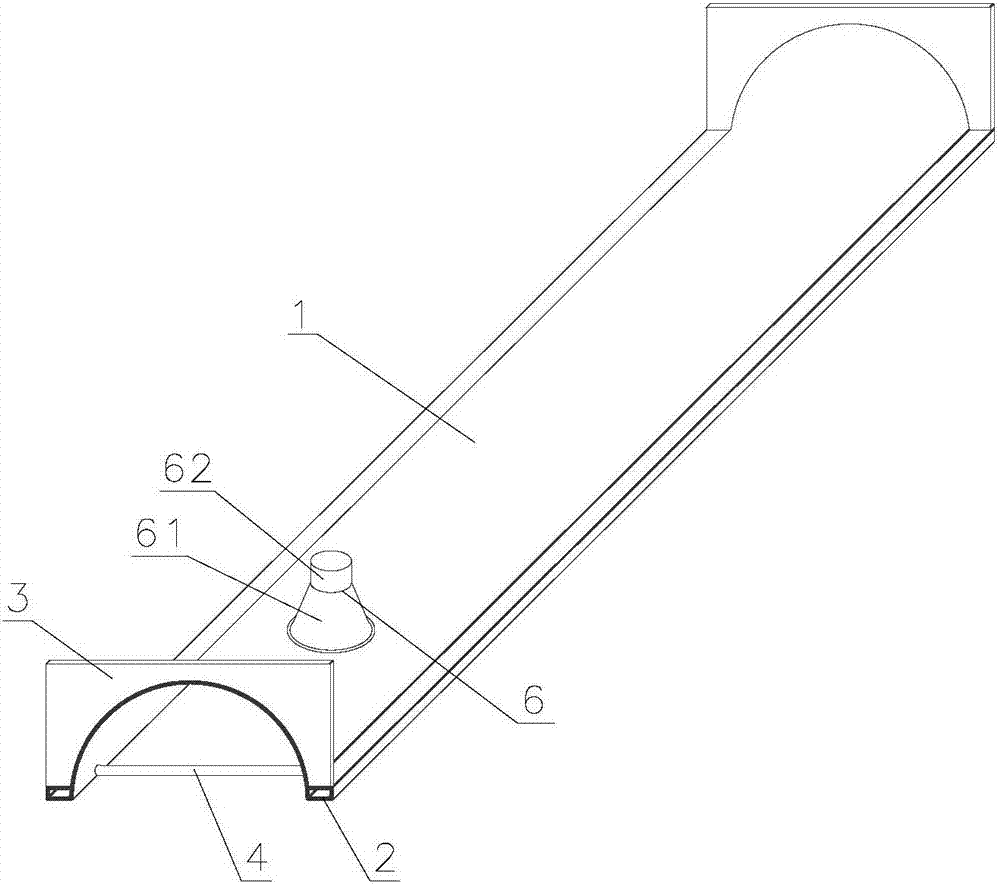

[0028] Such as figure 1 and figure 2 As shown, this embodiment provides an arc-shaped self-supporting gutter, which includes an arc-shaped wall plate 1 and flange curling 2 integrally formed by cold-bending thin-walled steel plates.

[0029] The flange curling 2 is mirror-imaged on the outer upper end of the arc-shaped wall plate 1 , the two ends of the arc-shaped wall plate 1 are provided with supports 3 , and the supports 3 are placed at the bottom of the arc-shaped wall plate 1 and the flange curling 2 . The inner side of the arc-shaped wall plate 1 is provided with a horizontal support rod 4, the support rod 4 is located on the upper part of the arc-shaped wall plate 1, and the center of the bottom surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com