Waste heat recovery for power generation and engine warming-up

A waste heat recovery and engine technology, applied in the direction of engine starting, engine components, combustion engines, etc., can solve problems such as increasing system cost and packaging space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

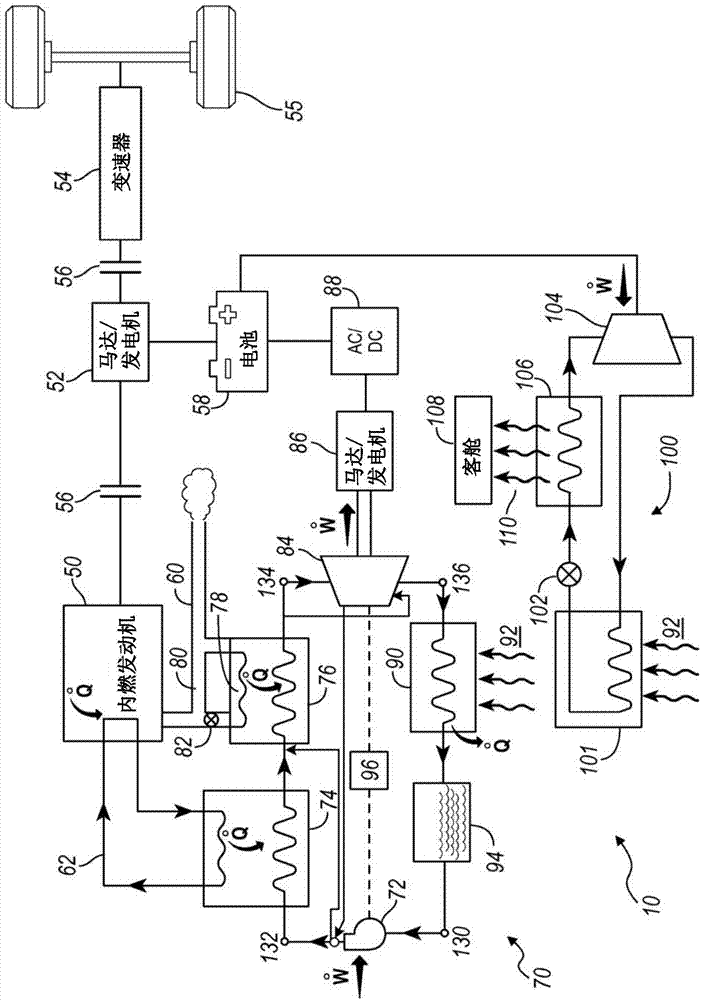

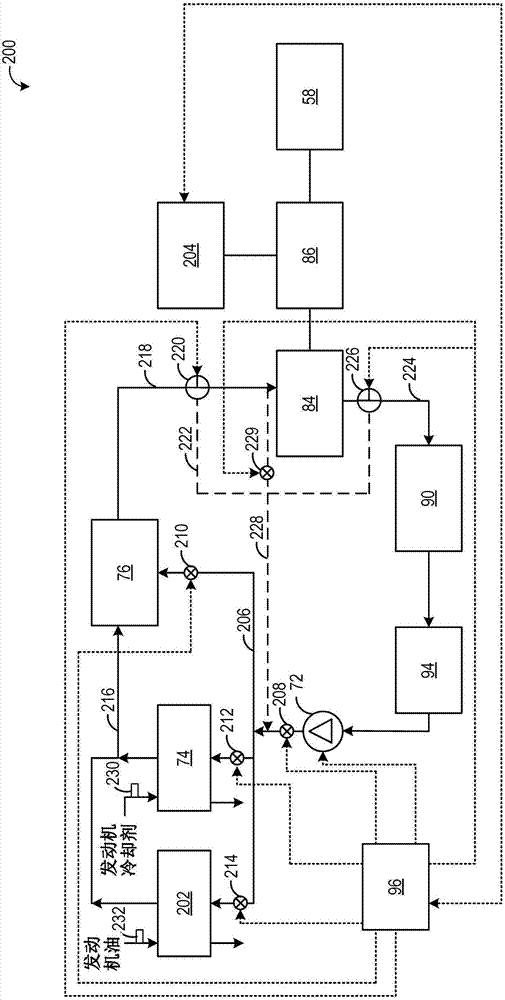

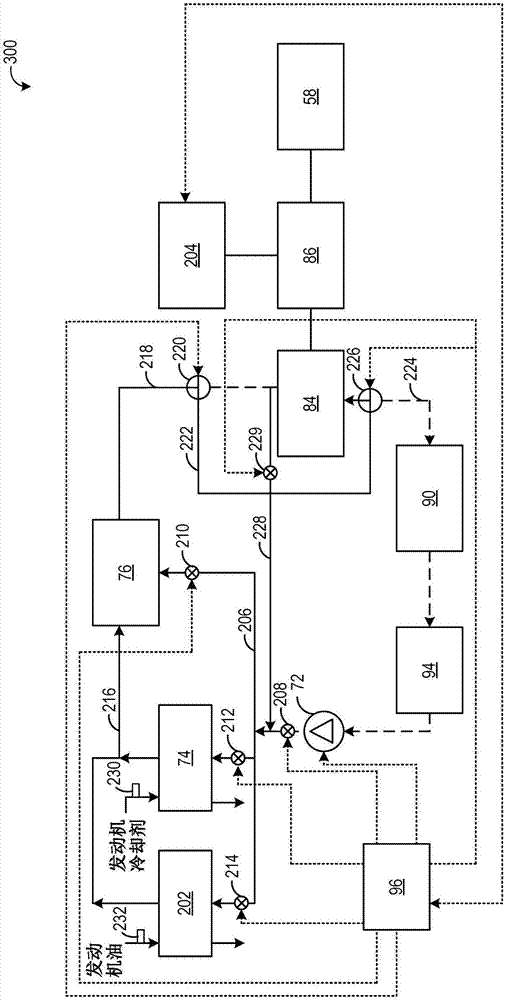

[0013] The Rankine cycle can be used to convert thermal energy into mechanical power or electricity. Efforts have been made to harvest thermal energy more efficiently or from more than one system that exhausts heat from the vehicle (such as engine coolant, engine or transmission oil, exhaust gas recirculation (EGR) gases, exhaust, etc.) waste heat. The present disclosure provides a waste heat recovery system for a Rankine cycle that is configured to operate in a warm-up mode or an engine cooling mode in addition to operating in a power generation mode. This is accomplished by including an additional working fluid flow path in the system and comprising a first flow path coupling the outlet of the evaporator to the outlet of the expander, and a second flow path A path couples the inlet of the expander to the outlet of the pump. During standard power generation mode, the expander operates in the forward direction to expand and extract mechanical energy from the working fluid, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com