Precision analysis and test method for test platform of robot harmonic reducer

A harmonic reducer and test platform technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems affecting the accuracy of the reducer, the imperfect transmission theory of the harmonic reducer, and the error of the harmonic reducer, so as to improve the real-time Effects on Sex and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

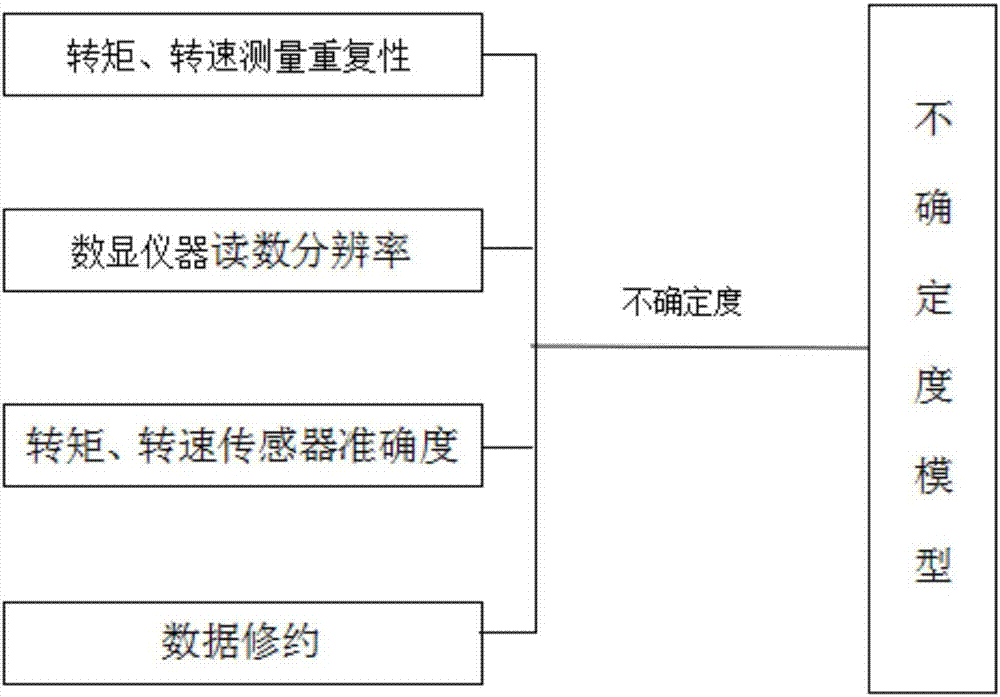

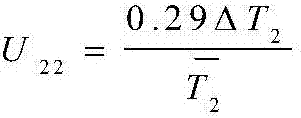

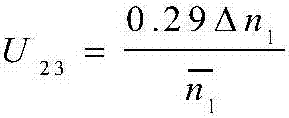

[0047]In order to better obtain accurate test data, the test system of this embodiment needs to take into account the influence of various uncertainty factors, wherein the sources of uncertainty include: the uncertainty introduced by the repeatability of torque and speed measurement, the digital display instrument Uncertainty introduced by reading resolution, uncertainty introduced by torque speed sensor accuracy, uncertainty introduced by data rounding off. Since the experimental conditions have no special requirements on the temperature, the uncertainty introduced by the temperature effect can be ignored. The coaxiality between the measured reducer and the sensor should ensure that the torque speed sensor meets its accuracy requirements, so its influence can be ignored. Therefore, in order to ensure the accuracy of the test accuracy of the test system, the key thing to solve is to study the uncertain propagation law, establish its related model, and then dynamically adjust i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com