Detection method of purity of 3-ethoxy-4-methoxybenzaldehyde

A methoxybenzaldehyde and detection method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of reliable detection method, high repeatability, and simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for detecting the purity of 3-ethoxy-4-methoxybenzaldehyde includes the following steps:

[0031] 1) System adaptability solution preparation: Take appropriate amount of 3-ethoxy-4-methoxybenzaldehyde, isovanillin and ethyl vanillin in the same volumetric flask, dissolve it with acetonitrile, and configure it to each milliliter A solution containing 1 mg of 3-ethoxy-4-methoxybenzaldehyde, isovanillin and ethyl vanillin to obtain a system suitability solution;

[0032] 2) Preparation of test product solution: Take an appropriate amount of test product 3-ethoxy-4-methoxybenzaldehyde, dissolve it with acetonitrile, and configure it into a solution with a concentration of 0.5 mg / mL to obtain the test product solution;

[0033] 3) Blank test: accurately measure 20μL of acetonitrile, inject it into the liquid chromatograph, and record the chromatogram;

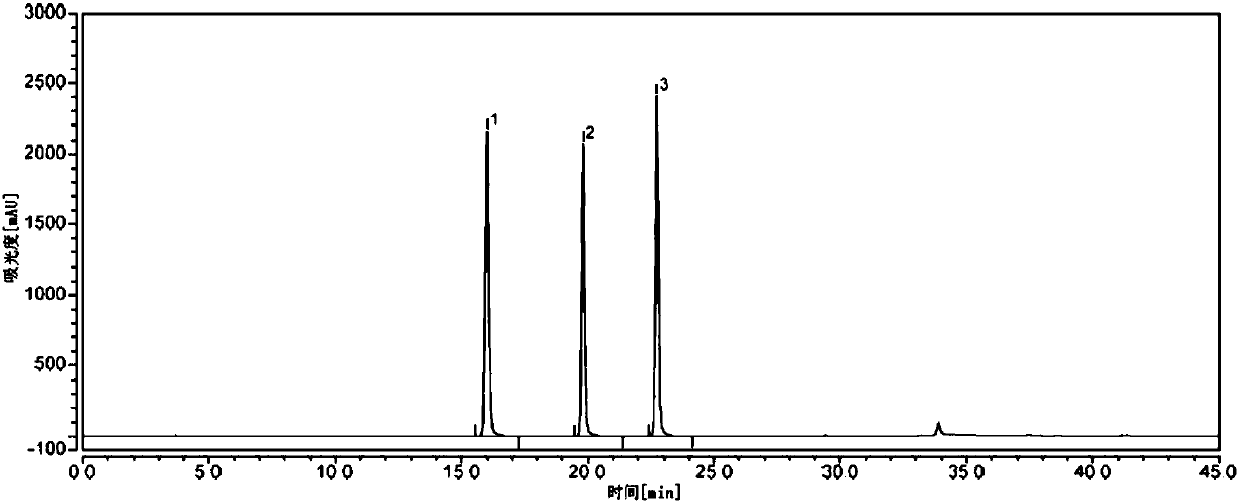

[0034] 4) System adaptability test: accurately measure 5μL of the system adaptability solution, inject it into the liquid ...

Embodiment 2

[0049] A method for detecting the purity of 3-ethoxy-4-methoxybenzaldehyde includes the following steps:

[0050] 1) System adaptability solution preparation: Take appropriate amount of 3-ethoxy-4-methoxybenzaldehyde, isovanillin and ethyl vanillin in the same volumetric flask, dissolve it with acetonitrile, and configure it to each milliliter A solution containing 1 mg of 3-ethoxy-4-methoxybenzaldehyde, isovanillin and ethyl vanillin to obtain a system suitability solution;

[0051] 2) Preparation of test product solution: Take an appropriate amount of test product 3-ethoxy-4-methoxybenzaldehyde, dissolve it with acetonitrile, and configure it into a solution with a concentration of 0.6 mg / mL to obtain the test product solution;

[0052] 3) Blank test: accurately measure 20μL of acetonitrile, inject it into the liquid chromatograph, and record the chromatogram;

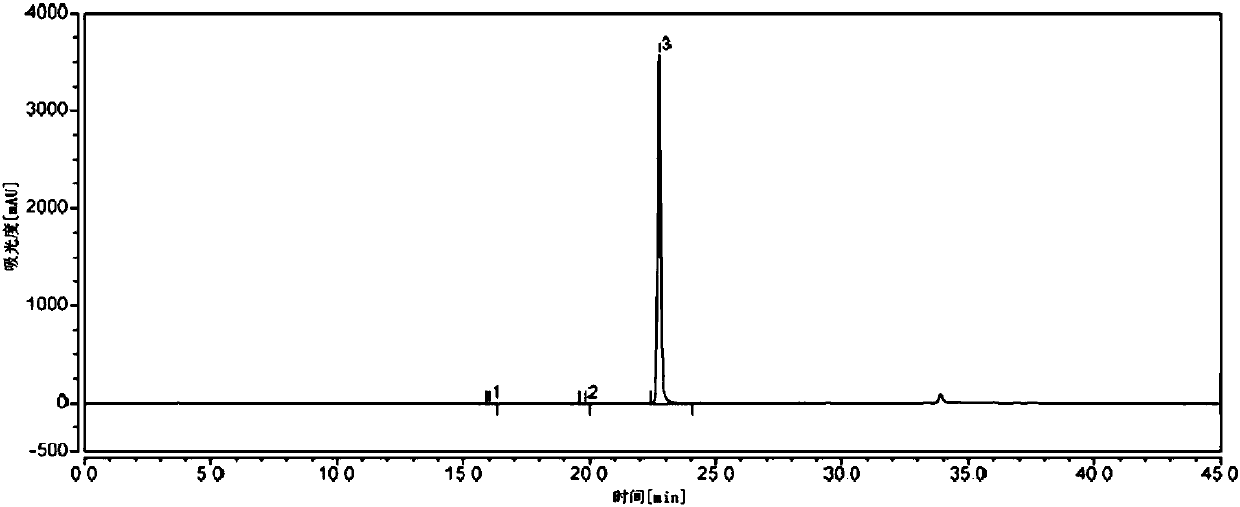

[0053] 4) System adaptability test: Precisely measure 10μL of the system adaptability solution, inject it into the liquid ...

Embodiment 3

[0062] A method for detecting the purity of 3-ethoxy-4-methoxybenzaldehyde includes the following steps:

[0063] 1) System adaptability solution preparation: Take appropriate amount of 3-ethoxy-4-methoxybenzaldehyde, isovanillin and ethyl vanillin in the same volumetric flask, dissolve it with acetonitrile, and configure it to each milliliter A solution containing 1 mg of 3-ethoxy-4-methoxybenzaldehyde, isovanillin and ethyl vanillin to obtain a system suitability solution;

[0064] 2) Preparation of test product solution: Take an appropriate amount of test product 3-ethoxy-4-methoxybenzaldehyde, dissolve it with acetonitrile, and configure it into a solution with a concentration of 0.5-1 mg / mL to obtain the test product solution;

[0065] 3) Blank test: accurately measure 20μL of acetonitrile, inject it into the liquid chromatograph, and record the chromatogram;

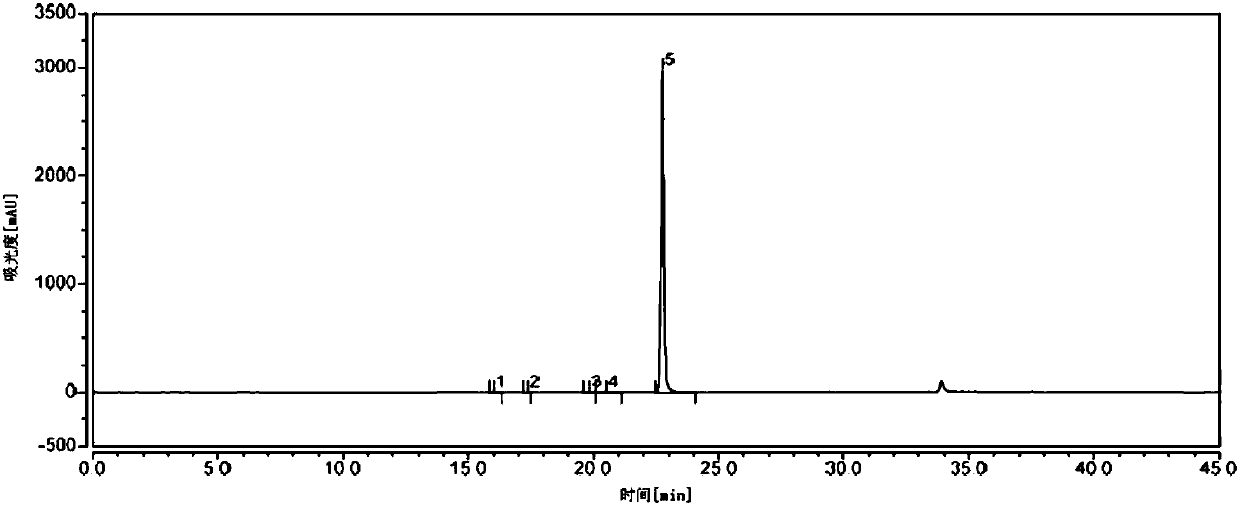

[0066] 4) System adaptability test: Precisely measure 15μL of the system adaptability solution, inject it into the liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com