A kind of solidified normal temperature yoghurt and preparation method thereof

A coagulation type, room temperature technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of rough cut surface, complex preparation method, high equipment requirements, and achieve the effect of high production efficiency, easy industrialization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

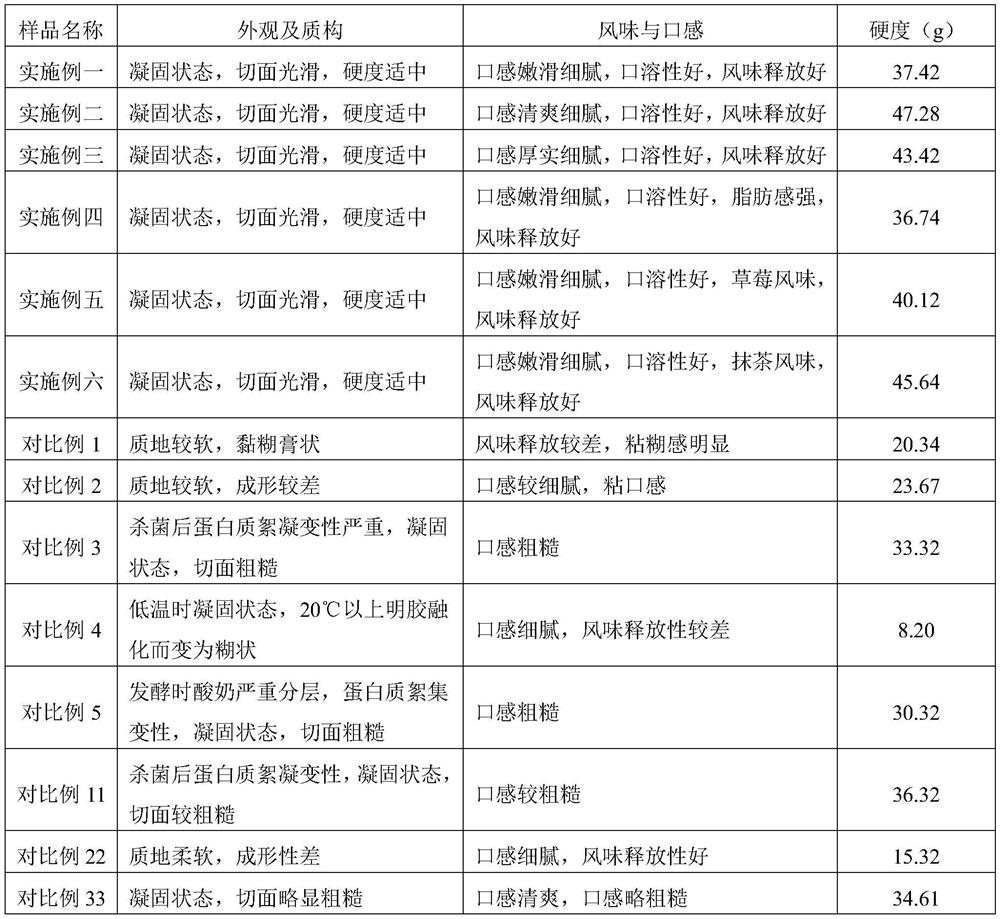

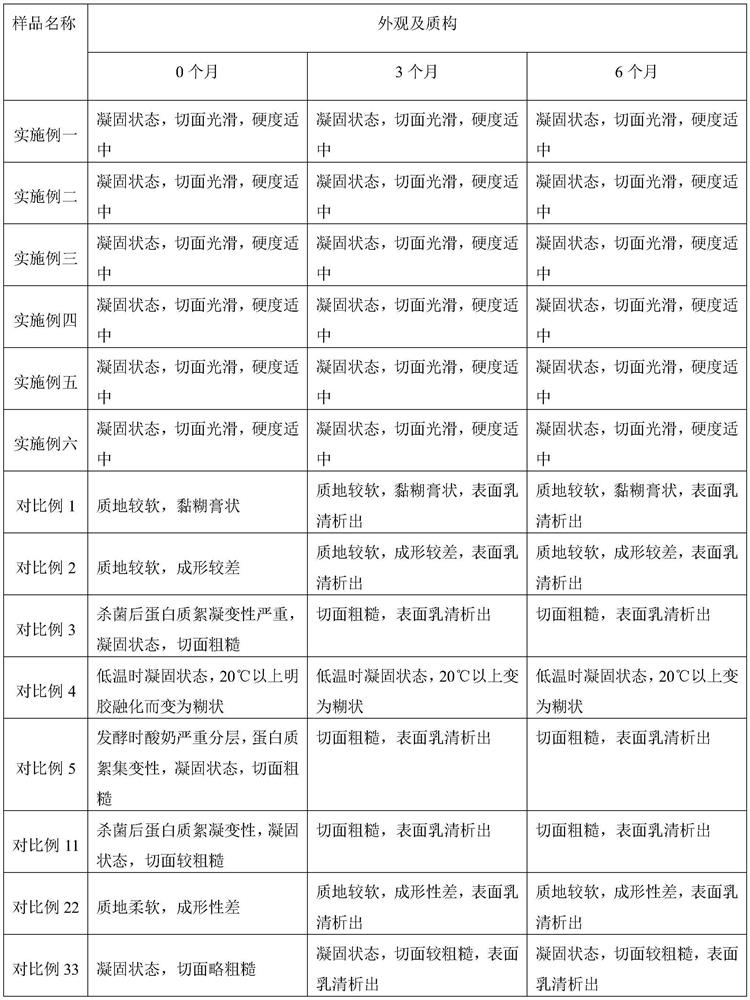

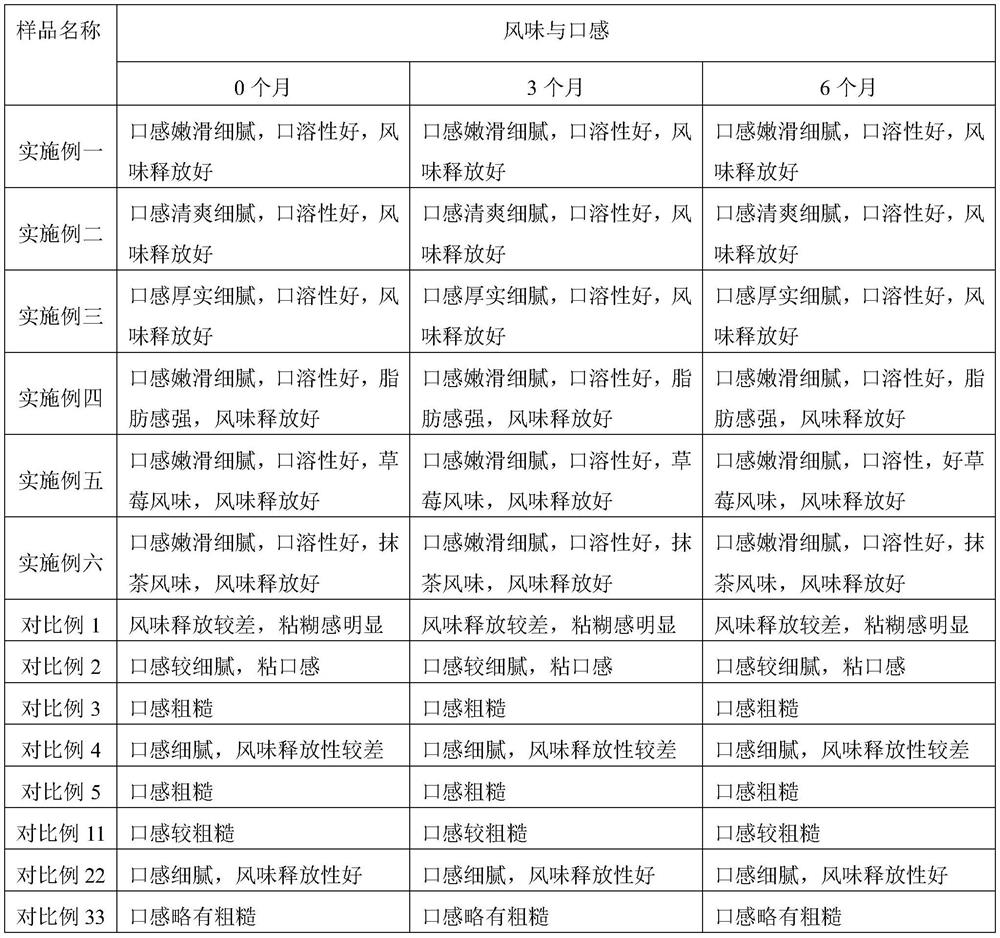

Examples

preparation example Construction

[0033] A kind of preparation method of setting type room temperature yoghurt of the present invention comprises the following steps:

[0034] 1) Take milk, heat it to 45-55°C, add milk protein products, cream products, sweeteners, flavor substances, agar and soybean polysaccharide under stirring conditions, heat up to 60-65°C, homogenize, and press 16-20MPa;

[0035] 2) Sterilize the homogenized feed liquid obtained in step 1) at 90-143° C., and the sterilization time is 4s-10 minutes;

[0036] 3) cooling the sterilized feed liquid obtained in step 2) to 36-43°C, adding lactic acid bacteria strains, and fermenting until the final acidity is 70-100°T, stirring evenly to obtain fermented milk;

[0037] 4) Homogenize the stirred fermented milk obtained in step 3), and the pressure is 5-15 MPa;

[0038] 5) Filling, water bath sterilization, 80~95℃, 5~30min;

[0039] 6) Cool down to below 20°C to obtain solidified yoghurt.

[0040] Preferably, in the step 5), the sterilization ...

Embodiment 1

[0042] A kind of preparation method of setting type room temperature yoghurt of the present invention comprises the following steps:

[0043] 1) Weigh the raw materials according to the following weight percentages for batching: white granulated sugar 8.0%, soybean polysaccharide 0.3%, agar 0.4%, lactic acid bacteria strain 50U / ton, and the balance is fresh milk;

[0044] 2) Take fresh milk, heat it to 45°C, add white granulated sugar, agar and soybean polysaccharide under stirring condition, heat up to 60°C, homogenize, and the homogenization pressure is 16MPa;

[0045] 3) Sterilize the homogenized feed liquid at 95°C for 5 minutes;

[0046] 4) Cool the sterilized feed solution to 43°C, add lactic acid bacteria, ferment until the final acidity is 70°T, stir evenly to obtain fermented milk;

[0047] 5) Homogenize the above-mentioned fermented milk after stirring evenly, and the pressure is 5MPa;

[0048] 6) Filling, water bath sterilization, 95°C, 5min;

[0049] 7) Place in...

Embodiment 2

[0051] A kind of preparation method of setting type room temperature yoghurt of the present invention comprises the following steps:

[0052] 1) Weigh the raw materials according to the following weight percentages for batching: 0.01% high-intensity sweetener, 0.4% soybean polysaccharide, 0.6% agar, 50U / ton of lactic acid bacteria strain, and the balance is skim milk;

[0053] 2) Take skim milk, heat it to 55°C, add high-intensity sweetener, agar and soybean polysaccharide under stirring conditions, heat up to 65°C, homogenize, and the homogenization pressure is 20MPa;

[0054] 3) Sterilize the homogenized feed liquid at 90°C for 10 minutes;

[0055] 4) Cool the sterilized feed liquid to 43°C, add the above strains to ferment until the final acidity is 70°T, and stir evenly to obtain fermented milk;

[0056] 5) Homogenize the above-mentioned fermented milk that has been stirred evenly, and the pressure is 5MPa;

[0057] 6) Filling, water bath sterilization, 80°C, 30min;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com