Method for reducing content of acrylamide and 5-hydroxymethyl furfural in deep-fried potato chips

A technology of hydroxymethylfurfural and acrylamide, which is applied to the functions of food ingredients, food ingredients as antioxidants, food science, etc., can solve the problems of low inhibition rate, reduce acrylamide, weaken Maillard reaction, etc., and achieve strengthening Health effect, safety improvement, effect of reducing intake of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Content of acrylamide and 5-hydroxymethylfurfural in potato chips not soaked in proanthocyanidin solution in embodiment 1

[0033] The method for fresh-cut fried potato chips without soaking in proanthocyanidin solution, the specific steps are as follows:

[0034] (1) Potatoes are washed and peeled, and cut into 2.0mm thick uniform slices with a slicer;

[0035] (2) Blanch the potato slices cut in step (1) in hot water at 95°C for 300s;

[0036] (3) cooling and drying the potato chips scalded in step (2);

[0037] (4) Fry the potato chips dried in step (3) in palm oil at 170° C. for 300 s.

[0038] It was determined that the content of acrylamide in potato chips soaked without proanthocyanidin solution was 767.9 μg / kg, and the content of 5-hydroxymethylfurfural was 1004.7 μg / kg.

Embodiment 2

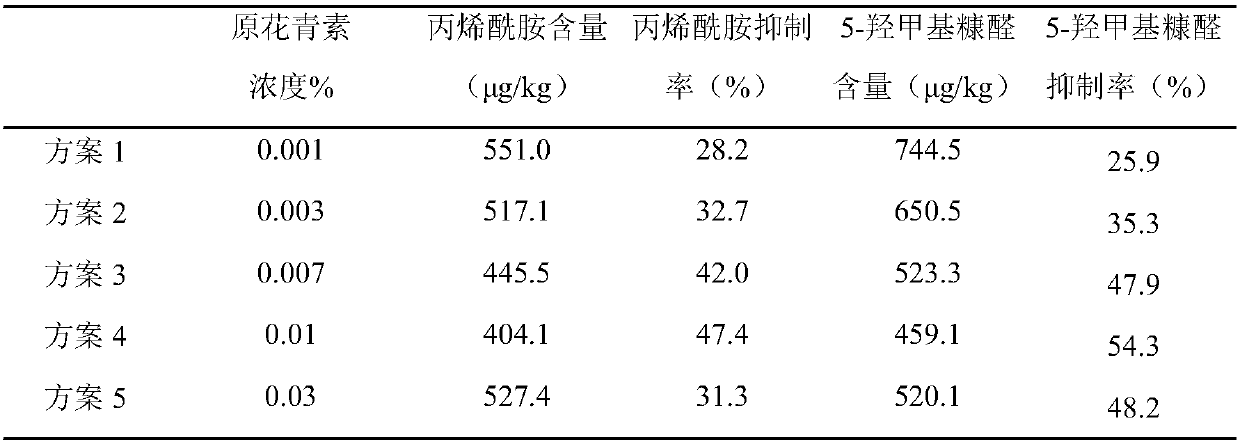

[0039] Embodiment 2 The influence of proanthocyanidin concentration on the inhibition rate of acrylamide and 5-hydroxymethylfurfural

[0040] A method for simultaneously reducing the content of acrylamide and 5-hydroxymethylfurfural in fresh-cut fried potato chips, the specific steps are as follows:

[0041] (1) Potatoes are washed and peeled, and cut into 2.0mm thick uniform slices with a slicer;

[0042] (2) Blanch the potato slices cut in step (1) in hot water at 95°C for 300s;

[0043] (3) Soak the potato slices blanched in step (2) in the sorghum proanthocyanidin solution (solution concentration as described in Table 1) at room temperature for 15 minutes;

[0044] (4) Drain the potato chips soaked in step (3);

[0045] (5) Fry the potato chips dried in step (4) in palm oil at 170°C for 300s.

[0046] Table 1 Effect of proanthocyanidin concentration on the inhibition rate of acrylamide and 5-hydroxymethylfurfural

[0047]

[0048] It can be seen from Table 1 that as...

Embodiment 3

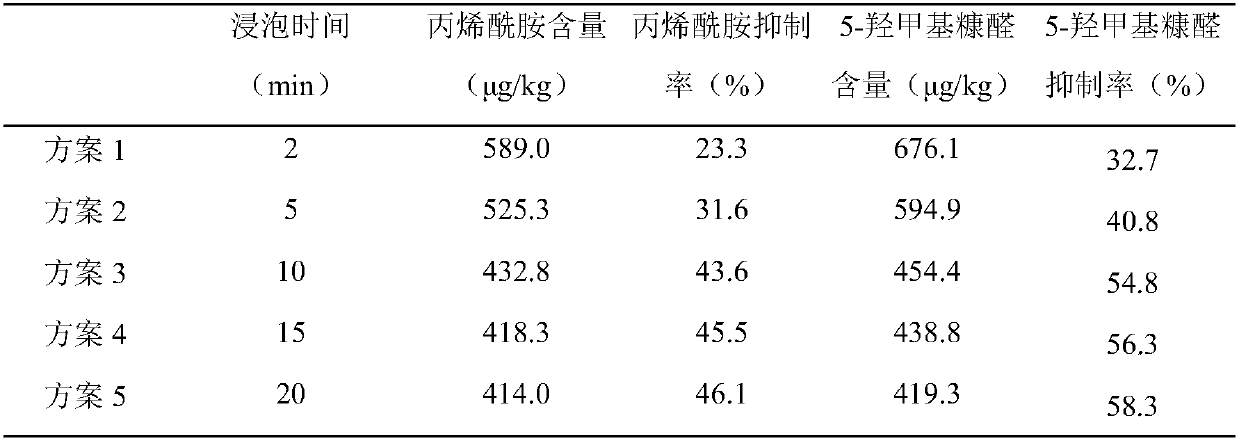

[0049] Embodiment 3 Proanthocyanidin solution immersion time is on the influence of acrylamide and 5-hydroxymethylfurfural inhibition rate

[0050] A method for simultaneously reducing the content of acrylamide and 5-hydroxymethylfurfural in fresh-cut fried potato chips, the specific steps are as follows:

[0051] (1) Potatoes are washed and peeled, and cut into 2.0mm thick uniform slices with a slicer;

[0052] (2) Blanch the potato slices cut in step (1) in hot water at 95°C for 300s;

[0053] (3) Soak the potato slices blanched in step (2) in a 0.01% grape seed proanthocyanidin solution at room temperature, and the soaking time is as described in Table 2;

[0054] (4) Drain the potato chips soaked in step (3);

[0055] (5) Fry the potato chips dried in step (4) in palm oil at 170°C for 300s.

[0056] Table 2 Effect of proanthocyanidin soaking time on the inhibition rate of acrylamide and 5-hydroxymethylfurfural

[0057]

[0058] It can be seen from Table 2 that as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com