Containment filtering and discharging system capable of efficiently removing organic iodine

A discharge system and containment technology, applied in radioactive purification, climate sustainability, nuclear power generation, etc., can solve problems such as the inability to remove organic iodine, and achieve the effects of reducing construction costs, high-efficiency filtration, and reducing equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

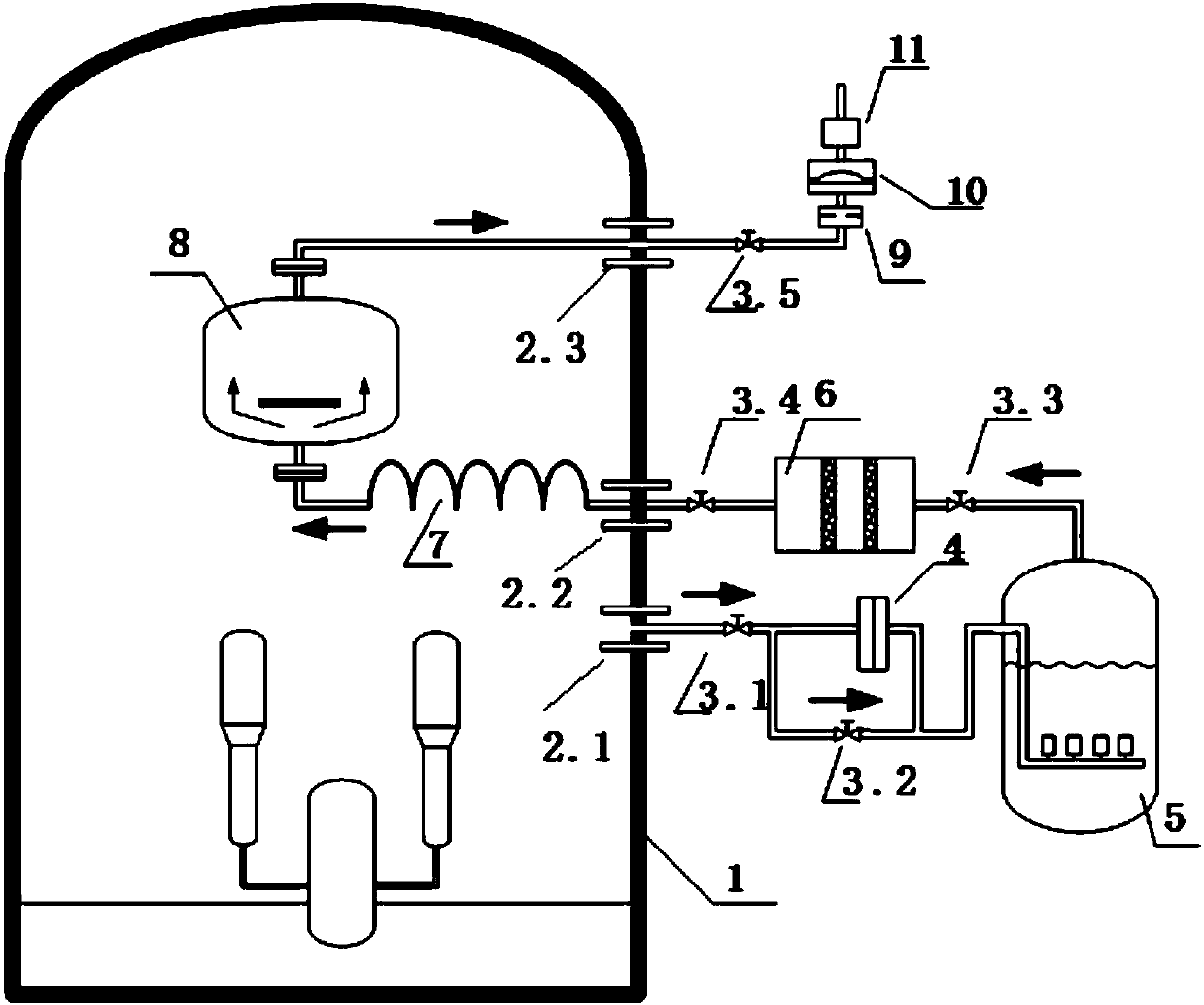

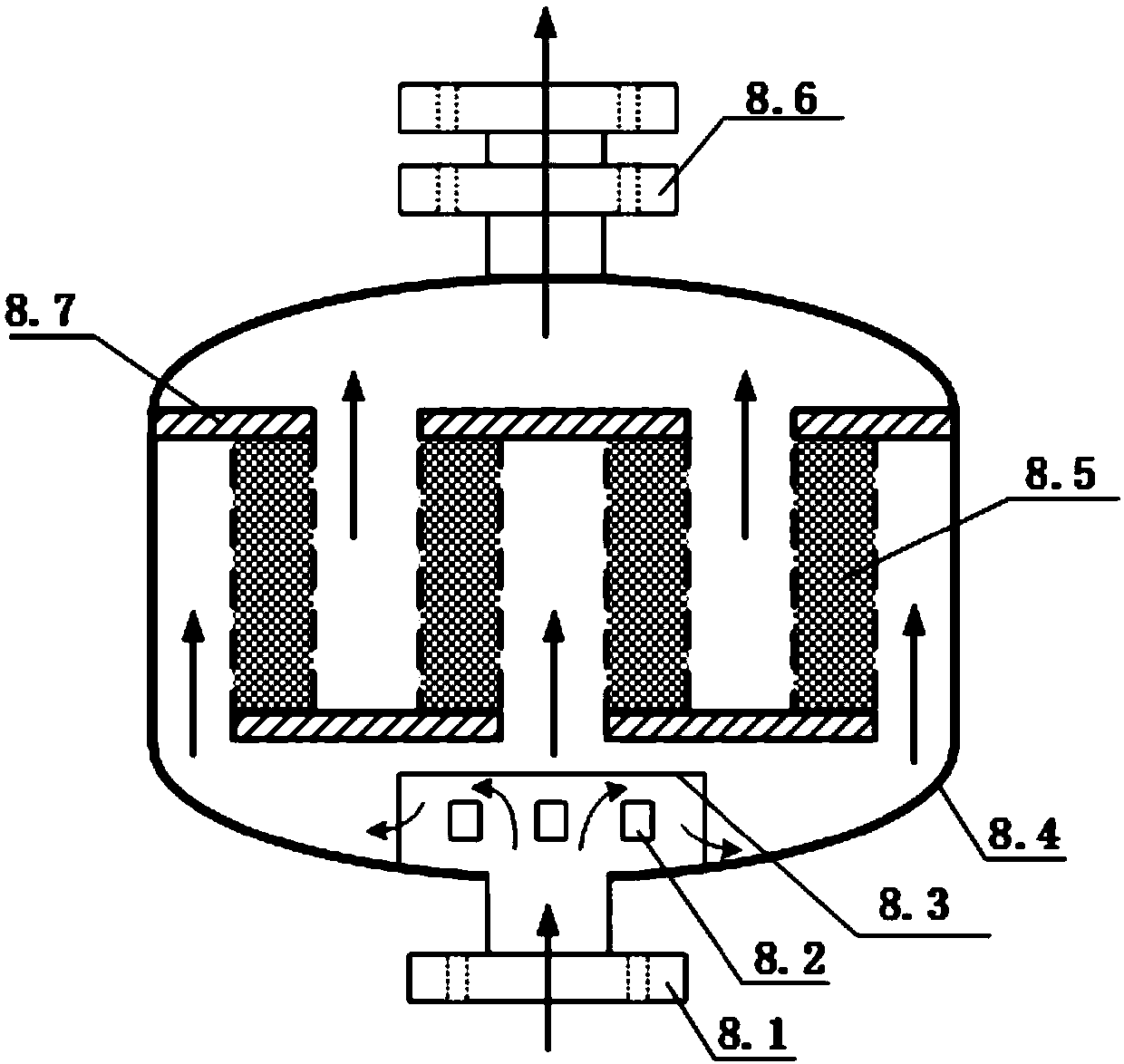

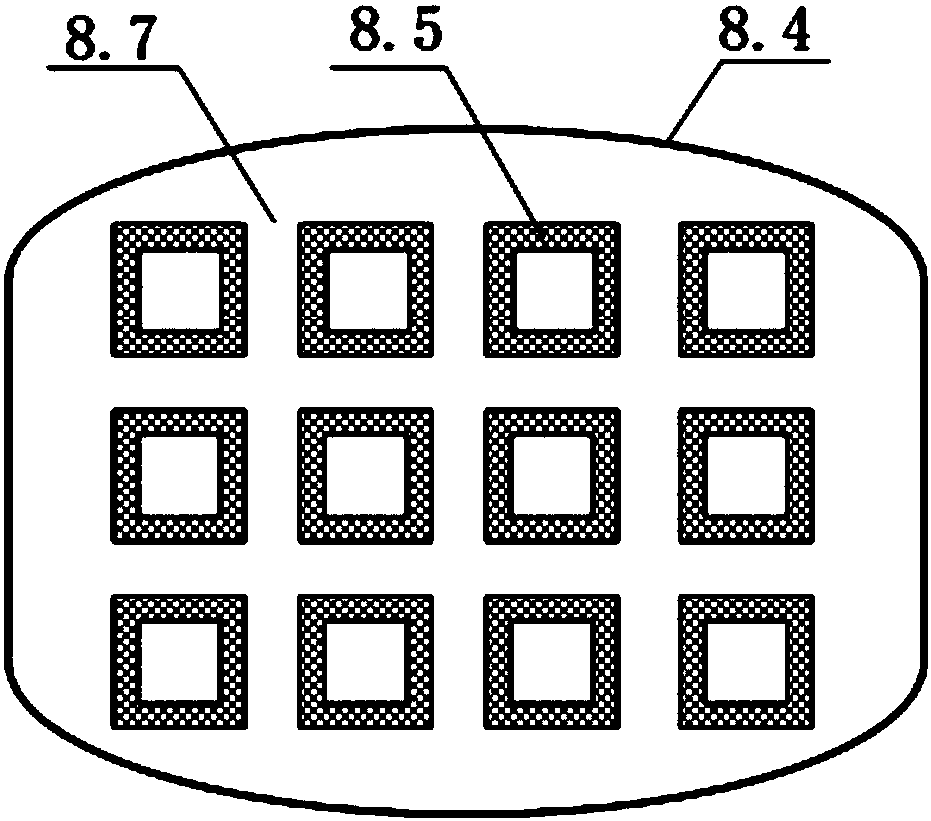

[0032] A containment filtration and discharge system capable of efficiently removing organic iodine, comprising a containment vessel 1, a penetration assembly, a containment isolation valve assembly, a burst membrane 4, a water washing filter 5, a metal fiber filter 6, and a spiral tube preheater 7. Silver zeolite filter 8, restricting orifice plate 9, burst membrane 2 10 and radioactive monitor 11;

[0033] The inlet pipeline of the containment filtration and discharge system penetrates into the containment 1 through the penetration component, and a containment isolation valve assembly is installed on the inlet pipeline; there are two parallel passages between the inlet pipeline and the inlet of the water washing filter, respectively active channel and passive channel, the containment isolation valve assembly is installed on the active channel, and a bursting disc-4 is installed on the passive channel; the inlet of the water-washing filter 5 is connected to external equipment ...

Embodiment 2

[0044] Such as figure 1 As shown, a containment filtration and discharge system for highly efficient removal of organic iodine consists of water-washed filters, metal fiber filters, spiral tube preheaters, silver zeolite filters, and corresponding pipeline valves.

[0045] The inlet pipeline of the containment filtration and discharge system penetrates into the containment 1 through the penetration piece 2, and a containment isolation valve 3 is installed on the inlet pipeline to isolate the containment 1 from the containment filtration and discharge system. There are two parallel passages between the isolation valve of the containment vessel and the inlet of the water wash filter, which are the active passage and the passive passage respectively. An isolation valve 3 is set on the active channel, and a rupture disc 4 is set on the passive channel. The inlet of the water washing filter 5 is connected with external equipment through a flange. The outlet of the water washing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com