Corrosion protection method for plasma processing device and gas channel

A gas channel and processing device technology, applied in the direction of electrical components, circuits, discharge tubes, etc., can solve the problems of etching result drift, metal pollution of cavity 10, high cost, etc., and achieve the effect of avoiding process result drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

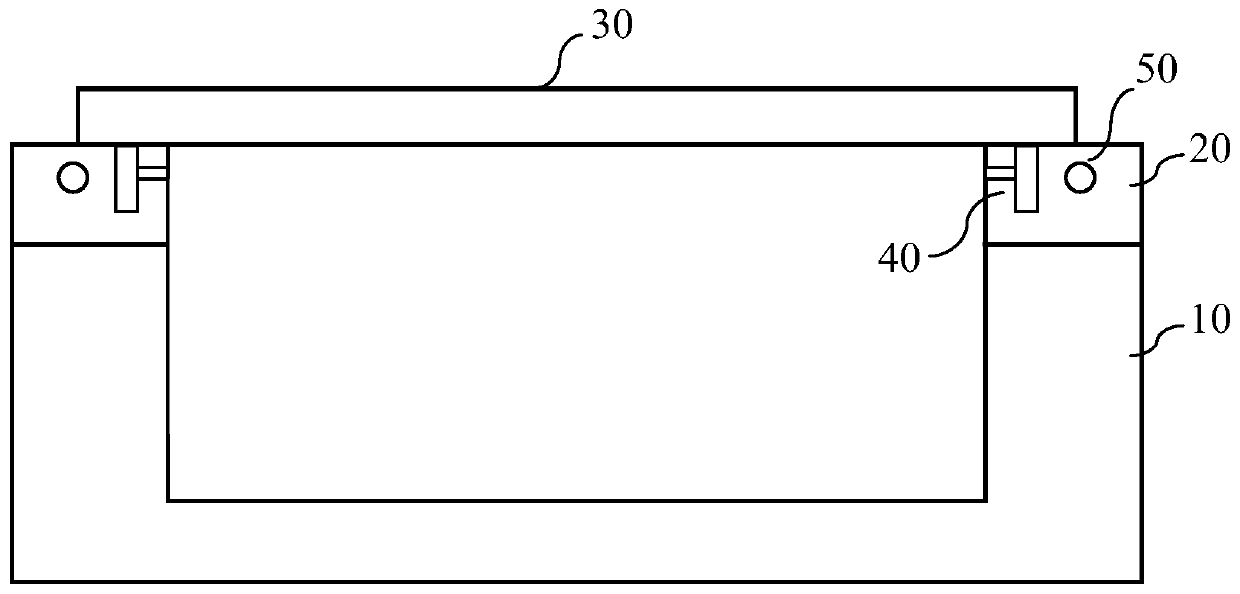

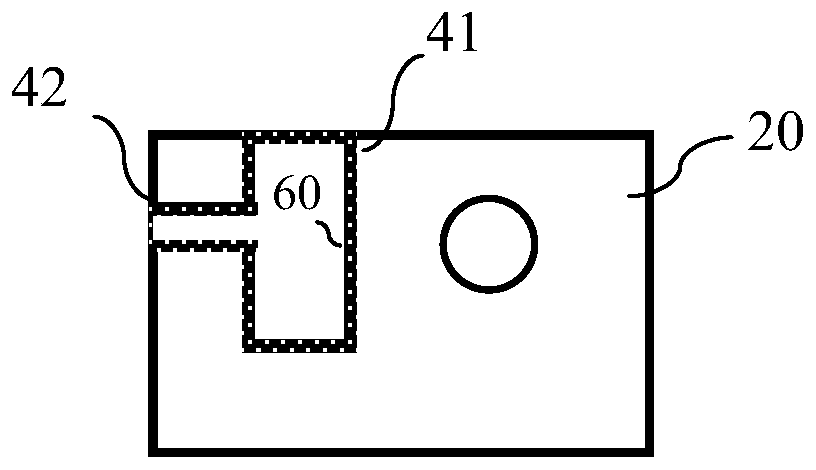

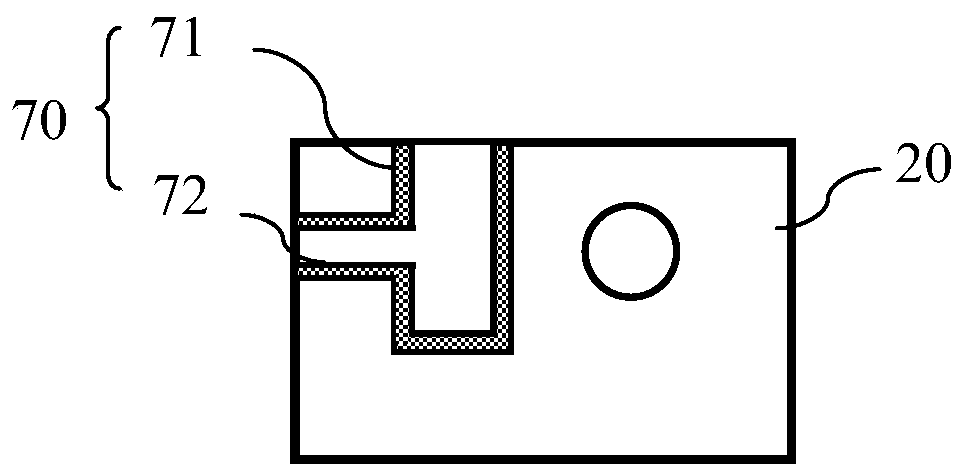

[0027] Cooperate see figure 1 , image 3 As shown, the present invention shows a plasma processing device, such as an inductively coupled plasma processing device (hereinafter referred to as an ICP device). Wherein, a ring-shaped chamber cover 20 is provided on the side wall of the chamber body 10 of the reaction chamber, and a dielectric window 30 is provided on the chamber cover 20 for arranging induction coils connected to radio frequency power and the like. A gas channel 40 is provided in the chamber cover 20 to introduce the reaction gas from the outside into the reaction chamber, and ionize to form a plasma of the reaction gas, which is used to etch the semiconductor substrate carried on the base at the bottom of the chamber.

[0028] In this example, the first passage 41 of the gas passage 40 is opened at the same annular position as the radial distance from the center of the chamber cover 20; The second channel 42 communicates with the second channel 42; the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com