A method to solve engine piston scuffing

A technology for engines and pistons, which is applied in the field of material surface modification, which can solve problems such as temperature rise, piston heat load increase, piston high-temperature strength and load-bearing capacity reduction, etc., and achieve the effect of increased anti-peeling strength and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

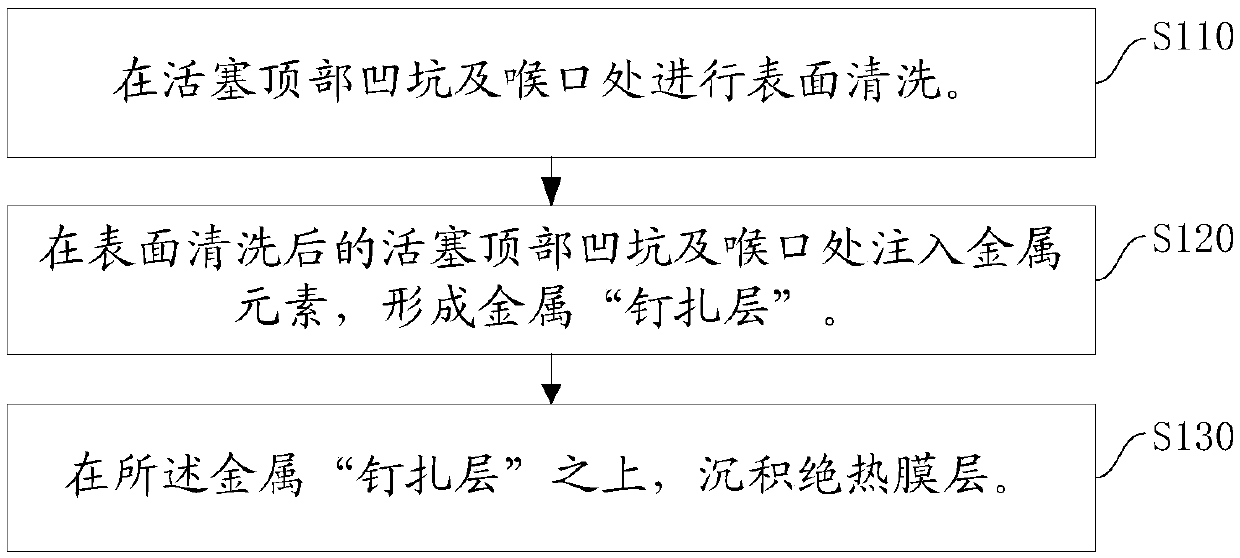

[0036] In order to solve the problem of piston pulling in the current engine, this embodiment provides a method to solve the problem of piston pulling in the engine. An insulating film is deposited at the top pit and throat of the piston to prevent the heat of the combustion chamber from going down the piston The conduction of key components solves the problem of piston pulling cylinder. figure 1 It is a schematic diagram of the process of depositing a thermal insulation film on the top pit and throat of the piston provided by an embodiment of the present invention, figure 2 It is a schematic diagram of the structure of a thermal insulation film provided by an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0037] S110: Perform surface cleaning at the pit and throat on the top of the piston.

[0038] In one example, metal ion beams are used to clean the surfaces of the pits and throats on the top of the piston to form a base layer. Preferabl...

Embodiment 2

[0047] Depositing Al in the pit and throat on the top of the piston 2 O 3 Insulation film. The implementation steps are as follows:

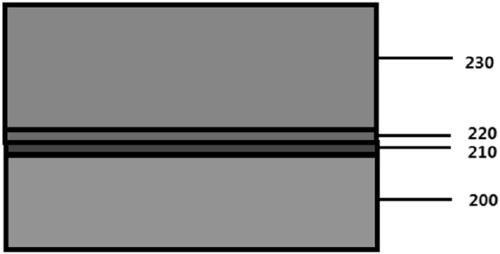

[0048] S110, preparation of metal cleaning layer 210

[0049] Al deposition: fixing the piston substrate 200 on the sample stage, rotating the sample to the deposition target position, and starting deposition, that is, cleaning the surface of the piston substrate 200 to obtain a metal cleaning layer 210. The deposition arc source is an Al arc source with a purity of 99%, and the deposition conditions are: vacuum 1×10 -3 -6×10 -3 Pa, deposition arc current: 100-120A, magnetic field current: 1.4-2.4A, arc current: 380-440mA, negative pressure: 400V-1000V, duty cycle 50%-100%, deposition time 3-60S, magnetic filter pipeline It is filtered at 90°.

[0050] S120, metal "pinning layer" 220 preparation:

[0051] Injection: rotate to the injection target to start injection, that is, inject metal ions on the metal cleaning layer 210 to obtain the metal "pinnin...

Embodiment 3

[0055] TiC-DLC insulation layer is deposited on the top of the piston and the throat. The implementation steps are as follows:

[0056] S110, preparation of metal cleaning layer 210:

[0057] Ti deposition: Fix the piston substrate 200 on the sample stage, and rotate the sample to the deposition target position to start deposition. The deposition arc source is a Ti arc source with a purity of 99%, and the deposition conditions are: vacuum 1×10 -3 -6×10 -3 Pa, deposition arc current: 100-110A, magnetic field current: 1.4-2.4A, arc current: 380-440mA, negative pressure: -400V-1000V, duty cycle 50%-100%, deposition time 3-60S, magnetic filter The pipe is filtered at 90°.

[0058] S120, preparation of metal "pinning layer" 220:

[0059] Injection: Turn to the injection target to start injection. The implanted ion source is pure Ti with a purity of 99.9%, and the implantation conditions are: vacuum degree 1×10 -3 -6×10 -3 Pa, injection arc voltage: 50-70V, injection voltage: 6-10kV, arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com