Film thickness measuring device and film thickness measuring method

A technology for measuring devices and film thickness, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not performing film thickness inspection, and achieve the effect of easy film thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0059]

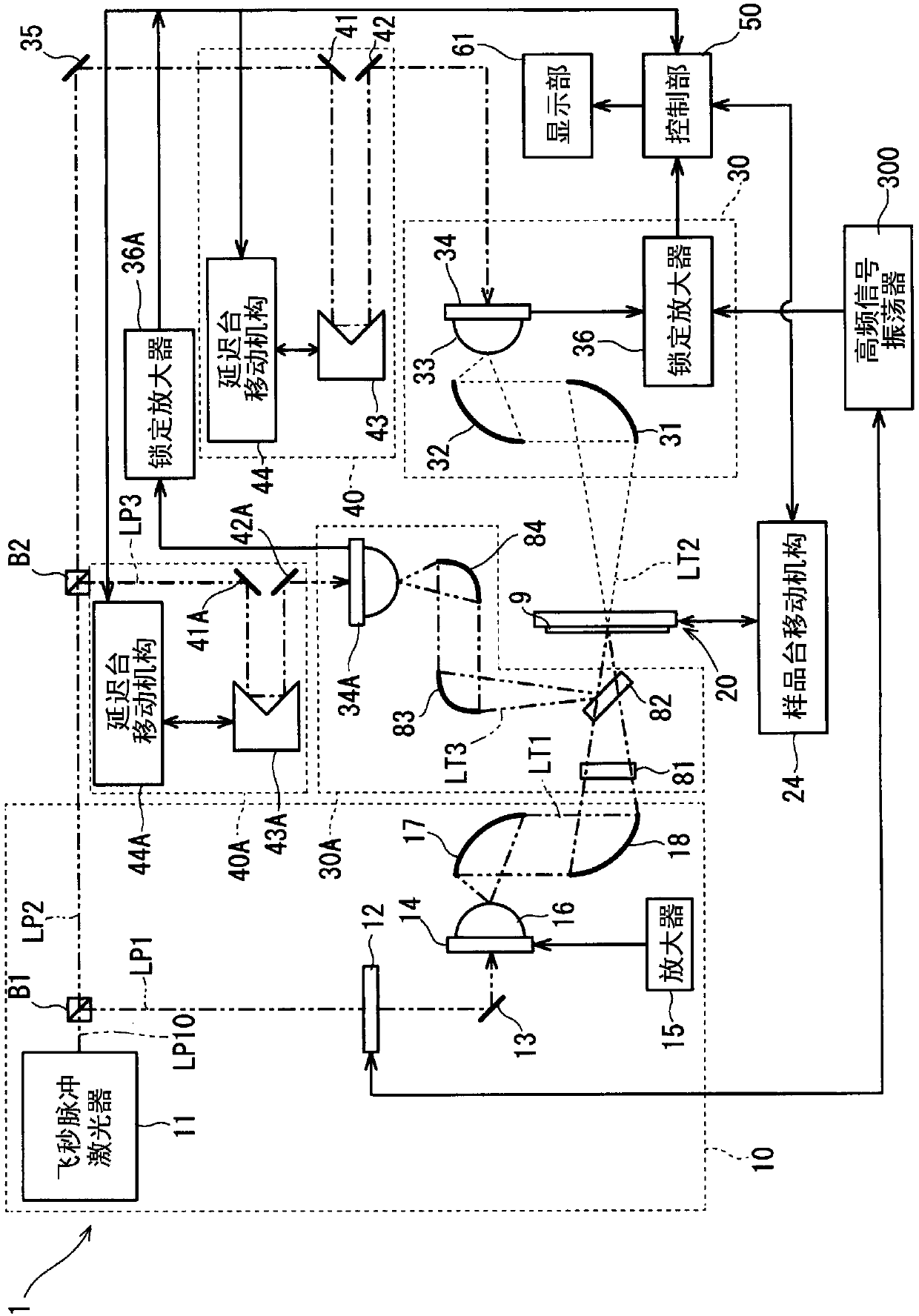

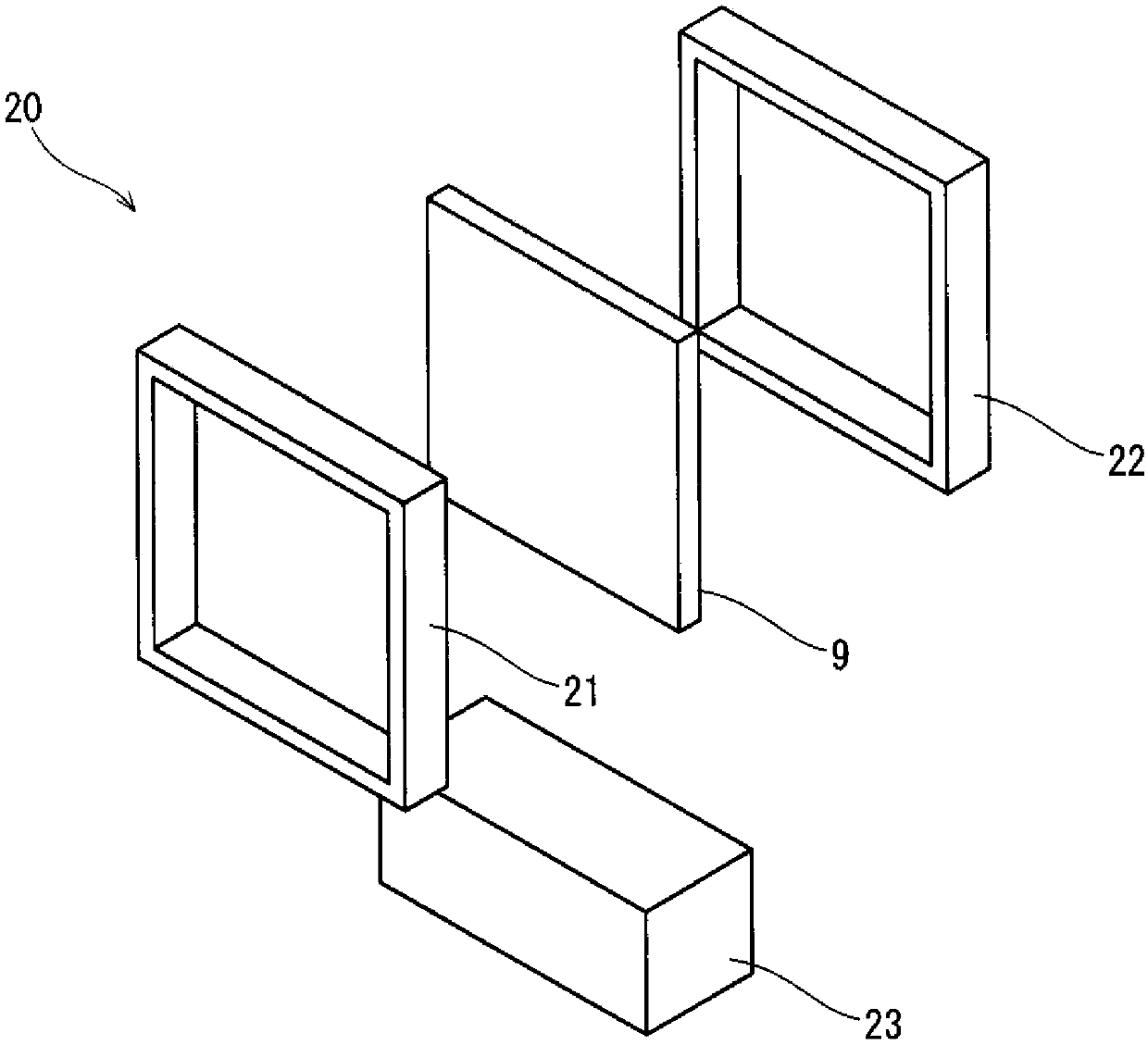

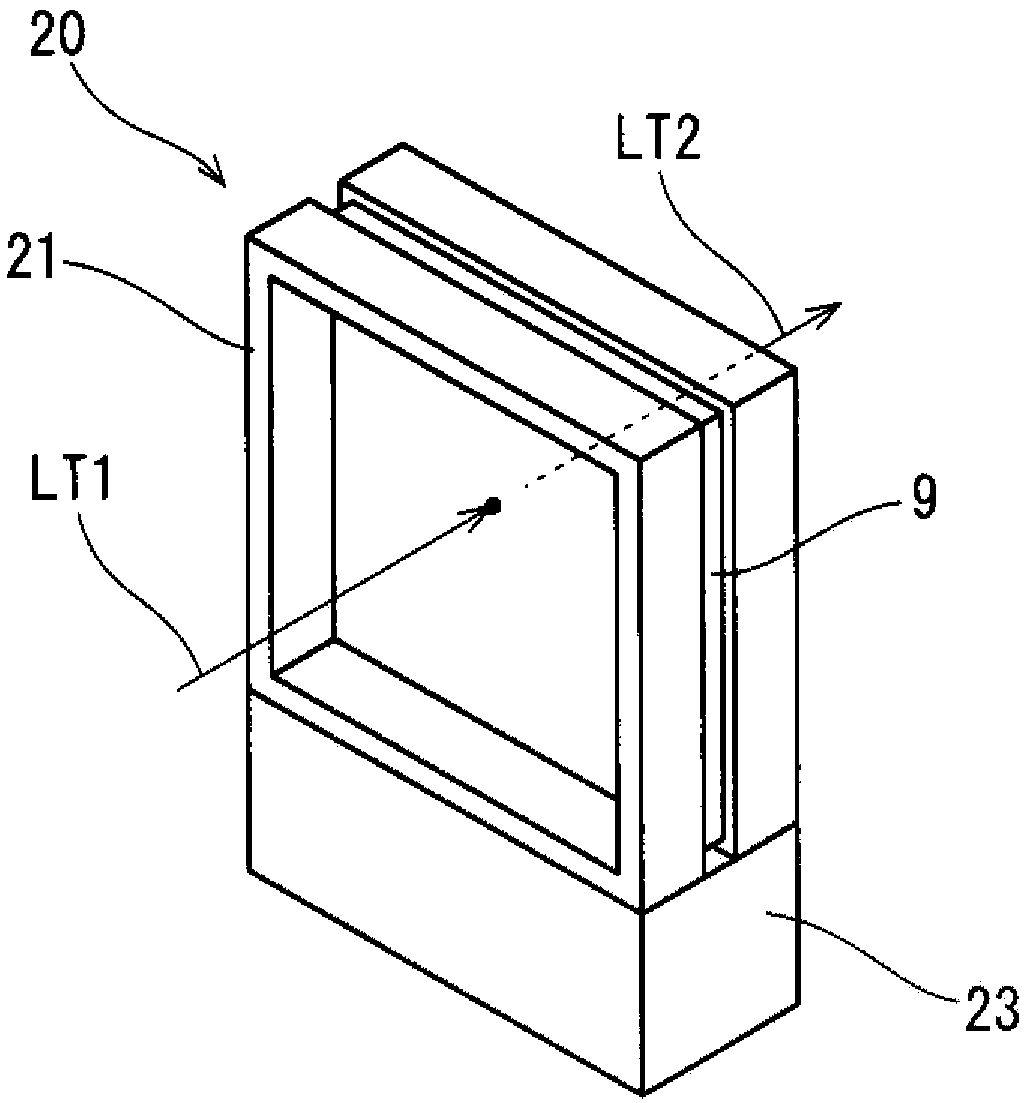

[0060] figure 1 It is a schematic configuration diagram showing the film thickness measurement device 1 of the first embodiment. Such as figure 1 As shown, the film thickness measurement device 1 includes a terahertz wave irradiation unit 10 , a sample stage 20 , a transmitted wave detection unit 30 , a reflected wave detection unit 30A, delay units 40 and 40A, and a control unit 50 . The transmitted wave detection unit 30 and the delay unit 40 constitute a refractive index acquisition system provided for acquiring the refractive index of a film containing an active material material (hereinafter referred to as “active material film”). In addition, the reflected wave detection unit 30A and the delay unit 40A constitute a film thickness measurement system provided for measuring the film thickness of the active material film.

[0061]

[0062] The terahertz wave irradiation unit 10 is configured to irradiate the sample 9 supported by the sample stage 20 with a ter...

no. 2 approach

[0172] Figure 18 It is a schematic side view showing an active material film forming system 100 incorporating the film thickness measuring device 1A of the second embodiment. The active material film forming system 100 is a system for forming the active material film 91 on one surface of a sheet-shaped current collector 93 conveyed in a roll-to-roll manner. This active material film forming system 100 includes a film thickness measurement device 1A that measures the film thickness of the active material film in the middle of the conveyance path of the current collector 93 .

[0173] In the active material film forming system 100 , the current collector 93 unwound from the unwinding roller 701 is conveyed to the coating unit 71 via the conveyance rollers 702 and 703 .

[0174] The coating unit 71 has a slit die 711 , a coating liquid supply unit 713 , and a backup roll 715 . The slit die 711 has a slit-shaped discharge port extending in the width direction of the current col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com