Liquid crystal display assembly

A liquid crystal display and component technology, applied in the direction of instruments, optical components, polarizing components, etc., can solve problems such as water leakage, bulky cooling components, and the need for regular water replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention attempt to actively maintain the temperature of the liquid crystal panel at the panel's specific operating temperature, especially in situations where the LCD cannot directly use conventional cooling methods, namely conduction and convection.

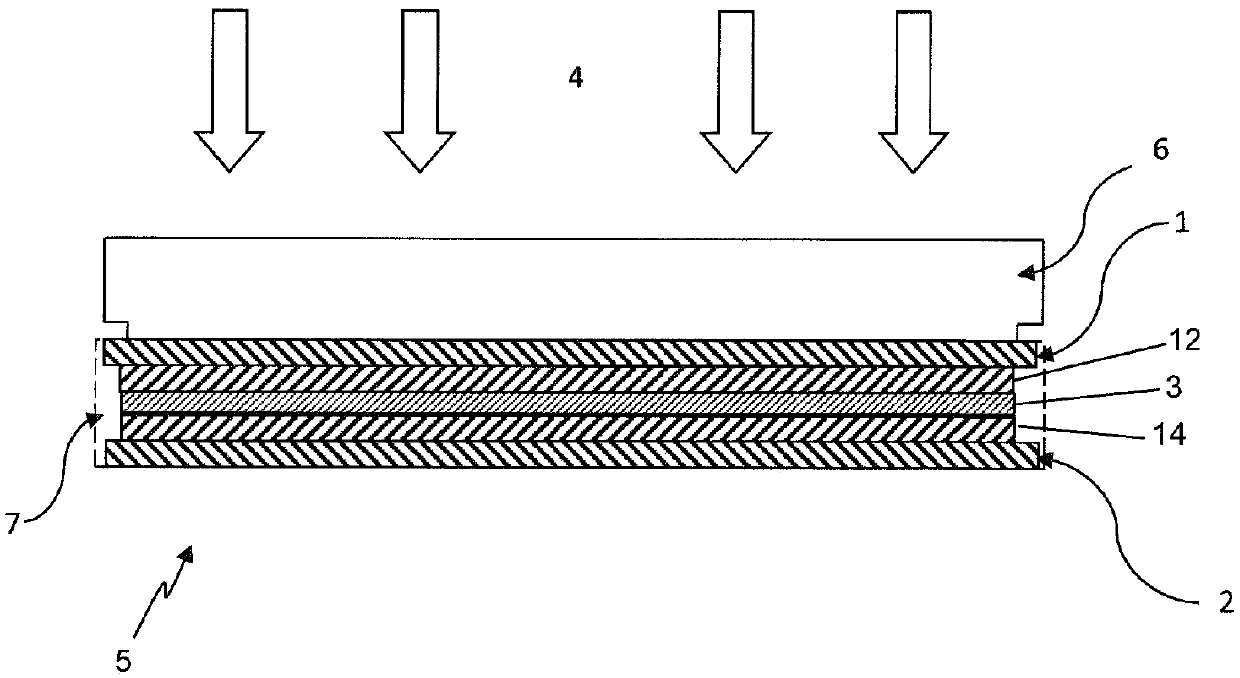

[0031] Referring to Figure 1, there is shown a prior art LCD assembly 5 having an LCD panel 7 secured to a rigid platform 6 that is transparent to electromagnetic radiation from the UV spectrum to the infrared spectrum. The platform 6 may be any material that is sufficiently rigid to prevent structural buckling on the LCD glass 12, 14 when the assembly is subjected to a vertical load. The LCD panel 7 includes a first polarizer 1 disposed on a first substrate 12 . The first substrate 12 and the second substrate 14 sandwich the liquid crystal material layer 3 . The second polarizer 2 is provided on the second substrate 14 . The first base plate 12 and the second base plate 14 serve to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com