Preparation method of fermented dried bambusa oldhami

A technology for horseshoe bamboo shoots and dried bamboo shoots is applied in the field of preparation of fermented dried horseshoe bamboo shoots, which can solve the problems of product flavor easily contaminated by miscellaneous bacteria, serious fibrosis, long production cycle, etc., and achieves shortened production cycle, low water content, The effect of raising the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

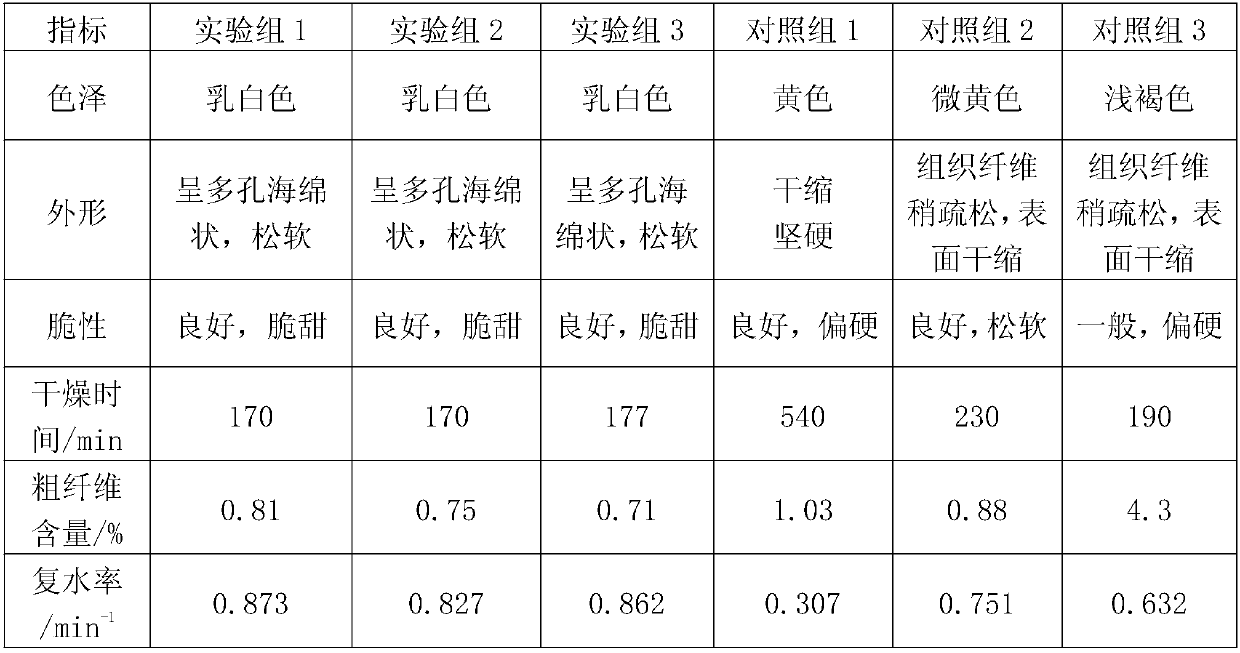

Examples

Embodiment 1

[0026] A preparation method for fermented dried water chestnut bamboo shoots, comprising the following steps:

[0027] (1) Cleaning: Clean the shelled water chestnut bamboo shoots and cut them into thin slices of 4-8cm×2-3cm×0.2-0.5cm;

[0028] (2) Pretreatment: soak the fresh bamboo shoot slices in step (1) with 0.02% baking soda solution for 5min, then use 0.08%NaCl and CaCl 2 The mixed solution was pre-boiled for 5 minutes, then soaked in 0.12% vinegar for 15 minutes, and finally steamed for 2 minutes for later use;

[0029] (3) Cleaning: Rinse the bamboo shoots pretreated in step (2) with water and cool to room temperature, drain the water for subsequent use;

[0030] (4) Fermentation: place the bamboo shoot slices after draining in a sealed fermenter, insert 3% saccharomyces to ferment, and ferment at 26° C. for 60 hours to obtain fermented dried bamboo shoots;

[0031] (5) Drying: The fermented bamboo shoots are first subjected to microwave drying process, the microwav...

Embodiment 2

[0035] A preparation method for fermented dried water chestnut bamboo shoots, comprising the following steps:

[0036] (1) Cleaning: Clean the shelled water chestnut bamboo shoots and cut them into thin slices of 4-8cm×2-3cm×0.2-0.5cm;

[0037] (2) Pretreatment: soak the fresh bamboo shoot slices in step (1) with 0.03% baking soda solution for 4min, then use 0.09%NaCl and CaCl 2 The mixed solution was preboiled for 3 minutes, then soaked in 0.13% vinegar for 13 minutes, and finally steamed for 3 minutes for later use;

[0038] (3) Cleaning: Rinse the bamboo shoots pretreated in step (2) with water and cool to room temperature, drain the water for subsequent use;

[0039] (4) Fermentation: place the drained bamboo shoots in a sealed fermenter, add 3% saccharomyces to ferment, and ferment for 55 hours at 27°C to obtain fermented dried bamboo shoots;

[0040] (5) Drying: The fermented bamboo shoots are first subjected to microwave drying process, the microwave power is 0.75kW / k...

Embodiment 3

[0044] A preparation method for fermented dried water chestnut bamboo shoots, comprising the following steps:

[0045] (1) Cleaning: Clean the shelled water chestnut bamboo shoots and cut them into thin slices of 4-8cm×2-3cm×0.2-0.5cm;

[0046] (2) Pretreatment: soak the fresh bamboo shoot slices in step (1) with 0.04% baking soda solution for 3min, then use 0.085%NaCl and CaCl 2 The mixed solution was pre-boiled for 3 minutes, then soaked in 0.14% vinegar for 13 minutes, and finally steamed for 2.5 minutes for later use;

[0047] (3) Cleaning: Rinse the bamboo shoots pretreated in step (2) with water and cool to room temperature, drain the water for subsequent use;

[0048] (4) Fermentation: place the drained bamboo shoots in a sealed fermenter, add 4% yeast to ferment, and ferment at 27°C for 57 hours to obtain fermented dried bamboo shoots;

[0049] (5) Drying: The fermented bamboo shoots are first subjected to microwave drying process, the microwave power is 0.78kW / kg, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com