High-speed vertical magnetic resorting system of composite magnetic field and sorting method thereof

A composite magnetic field and magnetic gravity separation technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of limited speed, increased heat generation and energy consumption, unreasonable tail running, etc., and achieve the speed of the shell. The effect of convenience, reduction of quantity and weight, and improvement of beneficiation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

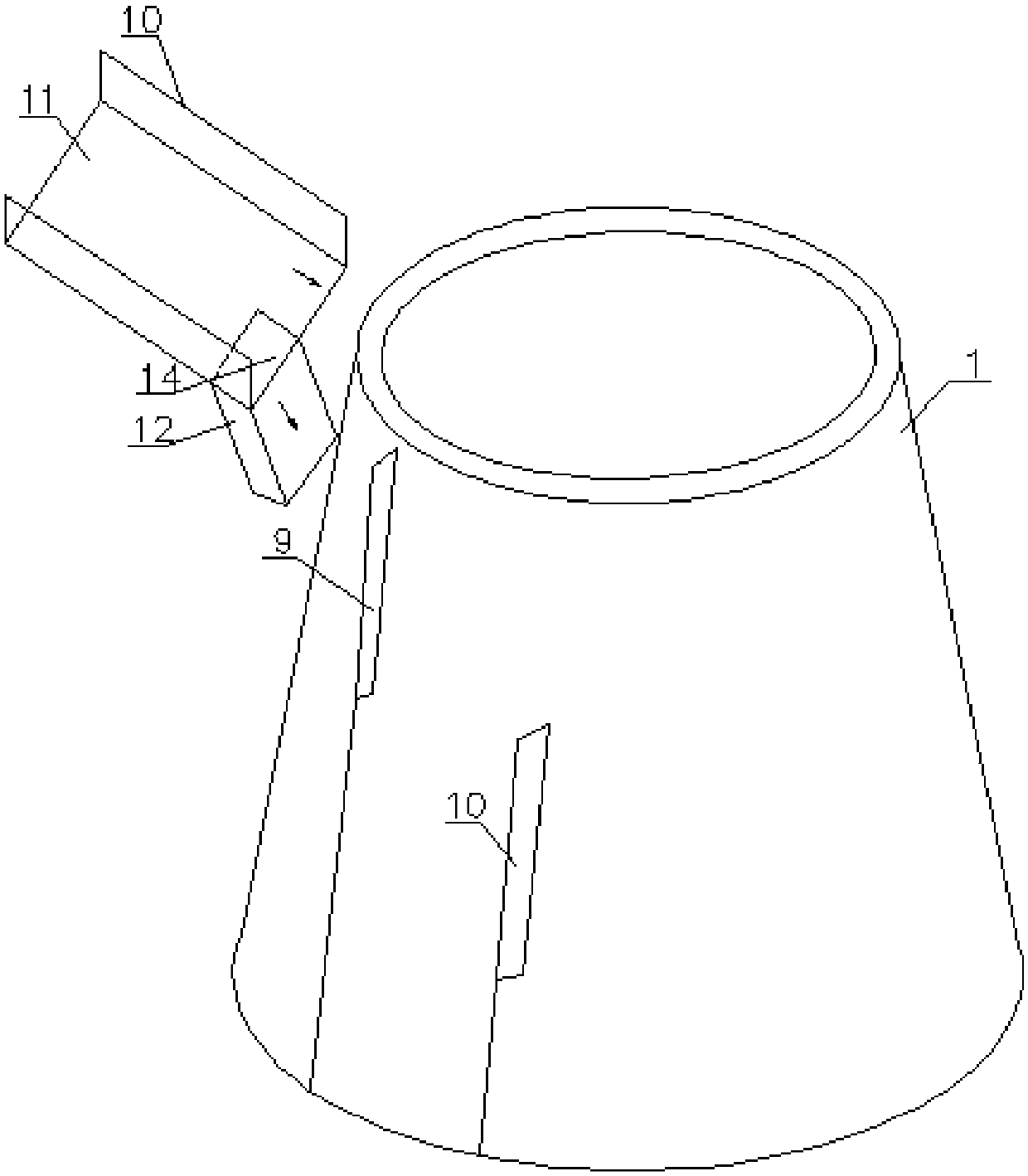

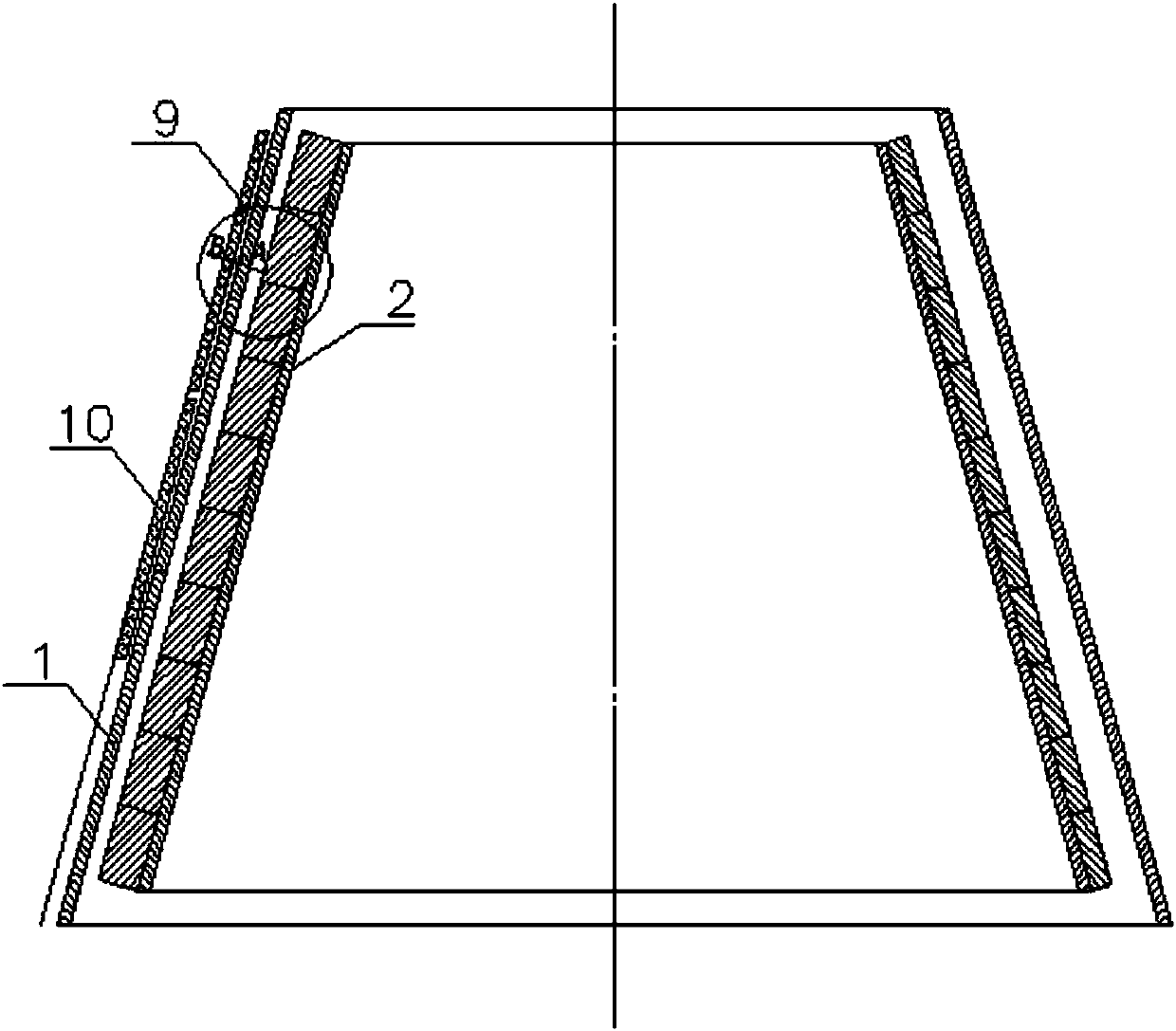

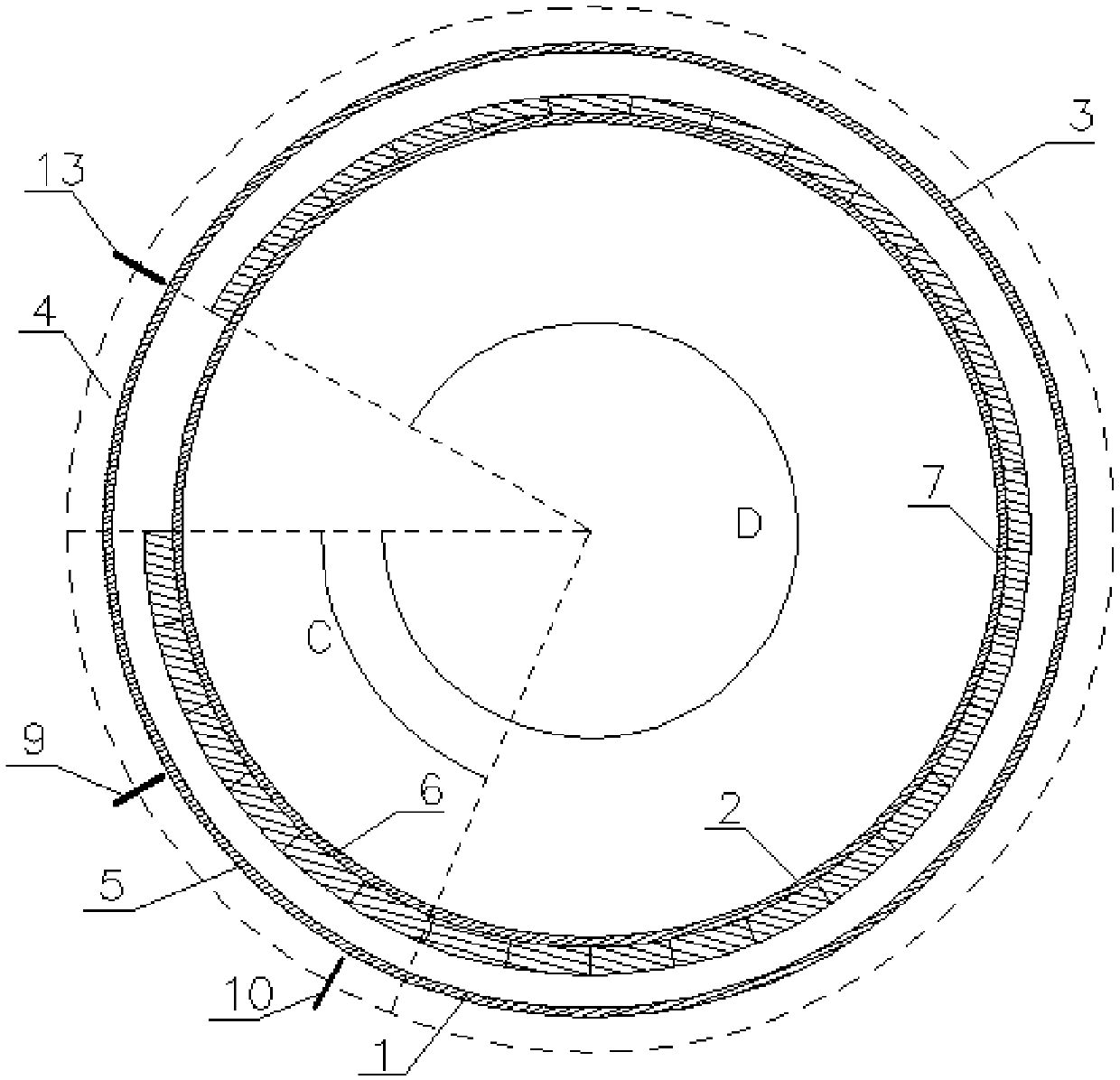

[0035] The compound magnetic field high-speed vertical magnetic gravity separation system includes an outer cylinder 1 and a magnetic system fixed cylinder 2, the outer cylinder 1 is set outside the magnetic system fixed cylinder 2, and there is a gap between the outer cylinder 1 and the magnetic system fixed cylinder 2; The magnetic system fixed cylinder 2 is provided with a magnetic block 8, and the magnetic blocks 8 are spliced into a magnetic system. The magnetic system is divided into a capturing magnetic system 6 and a sorting magnetic system 7. The outer cylinder 1 is divided into a mineral processing area 3, an ore unloading area 4 and a In mining area 5, the sorting middle and outer cylinder 1 rotates the magnetic system fixed cylinder 2 and stands still.

[0036] The capturing magnetic system 6 and the sorting magnetic system 7 are arranged along the circumferential direction of the outer edge of the magnetic system fixing cylinder 2, the total layout angle D of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com