A kind of Yellow River mud mortar building plaster dry material and preparation method thereof

A construction and mud-sand technology, applied in the field of Yellow River mud mortar building plaster dry material and its preparation, can solve problems such as high mud content, cracking of buildings, high water absorption, etc., and achieve the effect of solving silted river channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

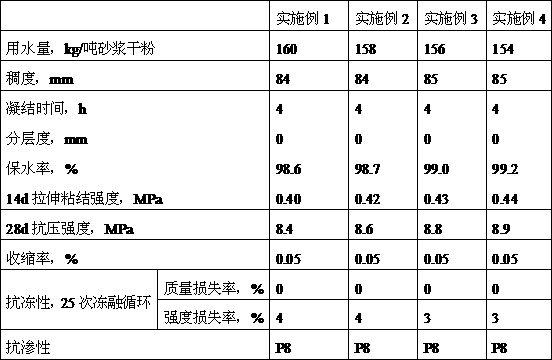

Examples

Embodiment 1

[0034] A kind of Yellow River mud mortar building plaster dry material, is made up of following raw material: Yellow River sand 65kg, cement 20kg, fly ash 8kg, gypsum 3kg and self-made adhesive 5kg;

[0035] Wherein self-made adhesive is obtained according to the following steps:

[0036] ① Dissolve 10kg of polyvinyl alcohol in 60kg of water, add 0.1kg of 30% hydrogen peroxide solution, stir and react for half an hour, add 10kg of dextrin water slurry, continue to stir and react for half an hour, and spray dry to obtain dextrin-modified polyvinyl alcohol particles ; Wherein the dextrin water slurry is obtained by uniformly mixing dextrin and water in a mass ratio of 1:3;

[0037] ② Add 1 kg of methyltrimethoxysilane to 10 kg of water and stir to obtain a solution, adjust the pH to 2 with hydrochloric acid, then heat up to 40 ° C for 10 hours to obtain a cross-linking solution, and then add 2 kg of hydroxypropyl methylcellulose to it, Stir and mix, and spray dry to obtain sila...

Embodiment 2

[0041] A kind of Yellow River mud mortar building plaster dry material, by weight, is made up of following raw material: Yellow River sand 80kg, cement 25kg, fly ash 12kg, gypsum 8kg and self-made adhesive 15kg;

[0042] Wherein self-made adhesive is obtained according to the following steps:

[0043] ① Dissolve 15kg of polyvinyl alcohol in 120kg of water, add 0.75kg of 30% hydrogen peroxide solution, stir for half an hour, add 30kg of dextrin water slurry, continue to stir for half an hour, and spray dry to obtain dextrin-modified polyvinyl alcohol Granules; wherein the dextrin water slurry is obtained by uniformly mixing dextrin and water in a mass ratio of 1:4;

[0044] ② Add 1kg of methyltrimethoxysilane to 15kg of water and stir to obtain a solution, adjust the pH to 3 with hydrochloric acid, then heat up to 50°C for 15 hours to obtain a cross-linking solution, and then add 5kg of hydroxypropylmethylcellulose to it , stirred and mixed, and spray-dried to obtain silane-mo...

Embodiment 3

[0048] A kind of Yellow River mud mortar building plaster dry material, is made up of following raw material: Yellow River sand 68kg, cement 24kg, fly ash 9kg, gypsum 4kg and self-made adhesive 8kg;

[0049] Wherein self-made adhesive is obtained according to the following steps:

[0050] ① Dissolve 20kg of polyvinyl alcohol in 130kg of water, add 0.4kg of 30% hydrogen peroxide solution, stir for half an hour, add 30kg of dextrin water slurry, continue to stir for half an hour, and spray dry to obtain dextrin-modified polyvinyl alcohol Granules; wherein the dextrin water slurry is obtained by uniformly mixing dextrin and water in a mass ratio of 1:3.5;

[0051] ② Add 1kg of methyltrimethoxysilane to 14kg of water and stir to obtain a solution, adjust the pH to 2.5 with hydrochloric acid, then heat up to 46°C and hydrolyze for 12 hours to obtain a crosslinking solution, and then add 4kg of hydroxypropyl methylcellulose to it, Stir and mix, and spray dry to obtain silane-modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com