A dust-proof grease composition for optical instruments and its preparation method

A technology for optical instruments and compositions, applied in the field of dust-proof grease compositions for optical instruments and their preparation, can solve the problems of obstructing observation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

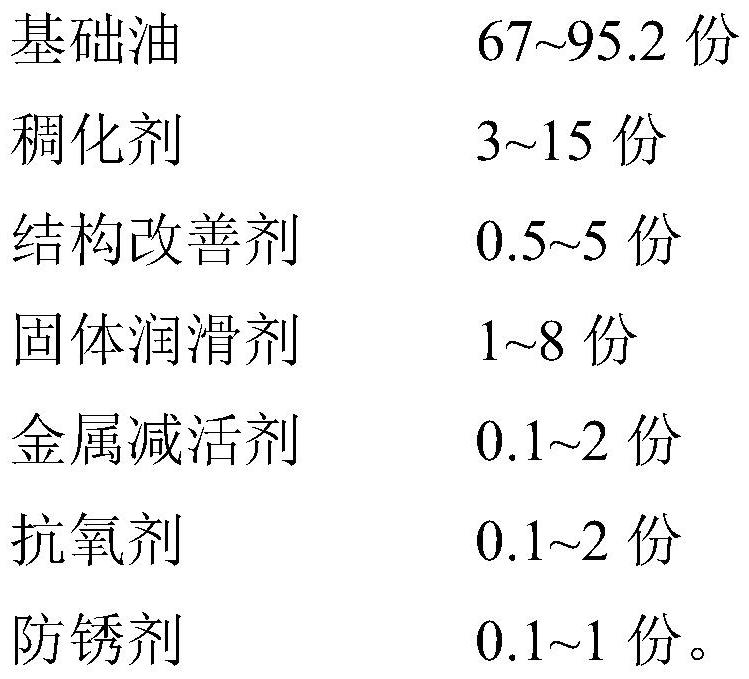

Method used

Image

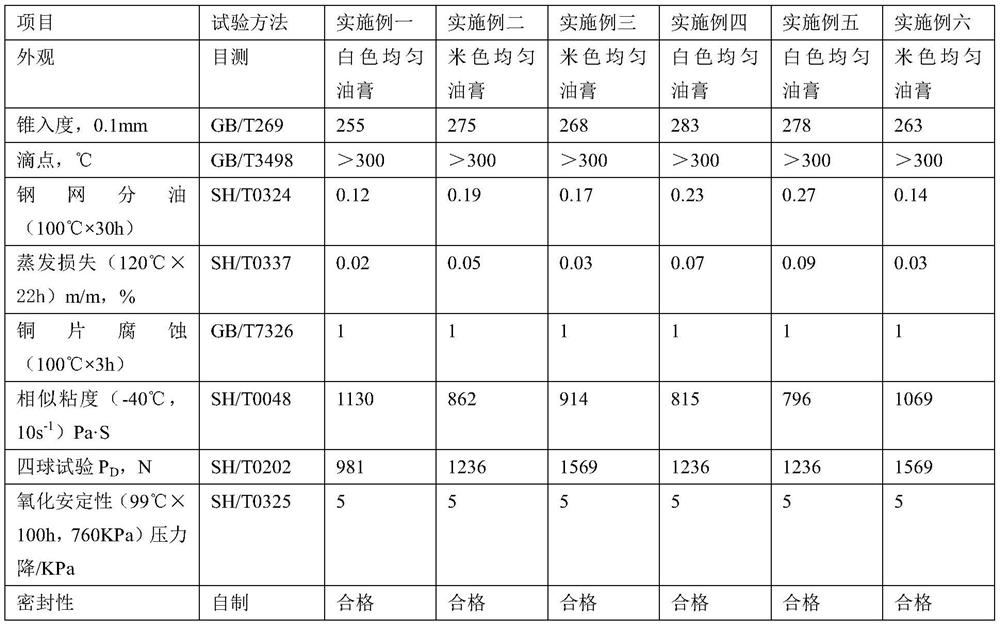

Examples

Embodiment 1

[0035] A kind of dustproof grease composition for optical instruments, its preparation method is:

[0036] Take 86.3 parts of dimethicone oil with a kinematic viscosity of 12500cst at 25°C and add it to the reaction kettle, heat it up to 90°C, add 2 parts of diphenyldihydroxysilane, heat it up to 150-155°C, and then add 6 parts of the specific surface area while stirring. 250m 2 / g of hydrophilic fumed silica, after the addition, the temperature was raised to 160° C., and puffed for 1.5 hours, and the puffing process was stirred for 3 minutes every 10 minutes. Then add 5 parts of polytetrafluoroethylene micropowder, 0.1 part of benzotriazole, 0.5 part of N-phenyl alpha naphthylamine, 0.1 part of basic barium dinonylnaphthalene sulfonate, and vacuumize to -0.05 after adding MPa, dehydration at constant temperature and vacuum for 1 hour. The material is discharged into a barrel and cooled to room temperature naturally, and the finished product is obtained by grinding it on a t...

Embodiment 2

[0038] A kind of dustproof grease composition for optical instruments, its preparation method is:

[0039] Take 16 parts of dimethicone oil with a kinematic viscosity of 12500cst at 25°C and 70.3 parts of dimethyl silicone oil with a kinematic viscosity of 1000cst at 25°C into the reaction kettle, heat up to 90°C, add 1 part of diphenyldihydroxysilane, and heat up to 150~ 155°C, then add 3 parts while stirring with a specific surface area of 250m 2 / g of hydrophilic fumed silica, add 3 parts after the addition, the specific surface area is 260m 2 / g of hydrophobic fumed silica, then the temperature was raised to 160° C. and expanded for 1.5 hours. During the expansion, stirring was performed for 3 minutes every 10 minutes. Then add 4 parts of polytetrafluoroethylene (PTFE) micropowder, 2 parts of molybdenum dialkyldithiocarbamate (MoDTC), 0.1 part of tolutriazole, and 0.5 part of diisooctyl diphenylamine, 0.1 part of After adding neutral barium dinonylnaphthalene sulfonate...

Embodiment 3

[0041] A kind of dustproof grease composition for optical instruments, its preparation method is:

[0042] Take 20 parts of dimethicone oil with a kinematic viscosity of 12500cst at 25°C and 66.8 parts of dimethyl silicone oil with a kinematic viscosity of 1000cst at 25°C into the reaction kettle, heat it up to 90°C, add 0.5 part of diphenyldihydroxysilane, and heat it up to 150~ 155 ℃, then add 2 parts while stirring, the specific surface area is 380m 2 / g of hydrophilic fumed silica, add 4 parts after the addition, the specific surface area is 260m 2 / g of hydrophobic fumed silica, then the temperature was raised to 160° C. and expanded for 1.5 hours. During the expansion, stirring was performed for 3 minutes every 10 minutes. Then add 3 parts polytetrafluoroethylene (PTFE) micropowder, 3 parts molybdenum dialkyldithiocarbamate (MoDTC), 0.1 part benzotriazole, and 0.5 part diisooctyl diphenylamine, 0.1 part neutral Barium dinonylnaphthalene sulfonate, vacuumize to -0.05MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com