Preparation method of acoustic material

A technology of sound-absorbing materials and warp and weft yarns is applied in the field of preparation of high-strength sound-absorbing materials, which can solve the problems of weak mechanical strength, easy burning and aging resistance, and achieve high-efficiency sound-absorbing effect, compact structure and good integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: A polyester fiber sound-insulating fabric

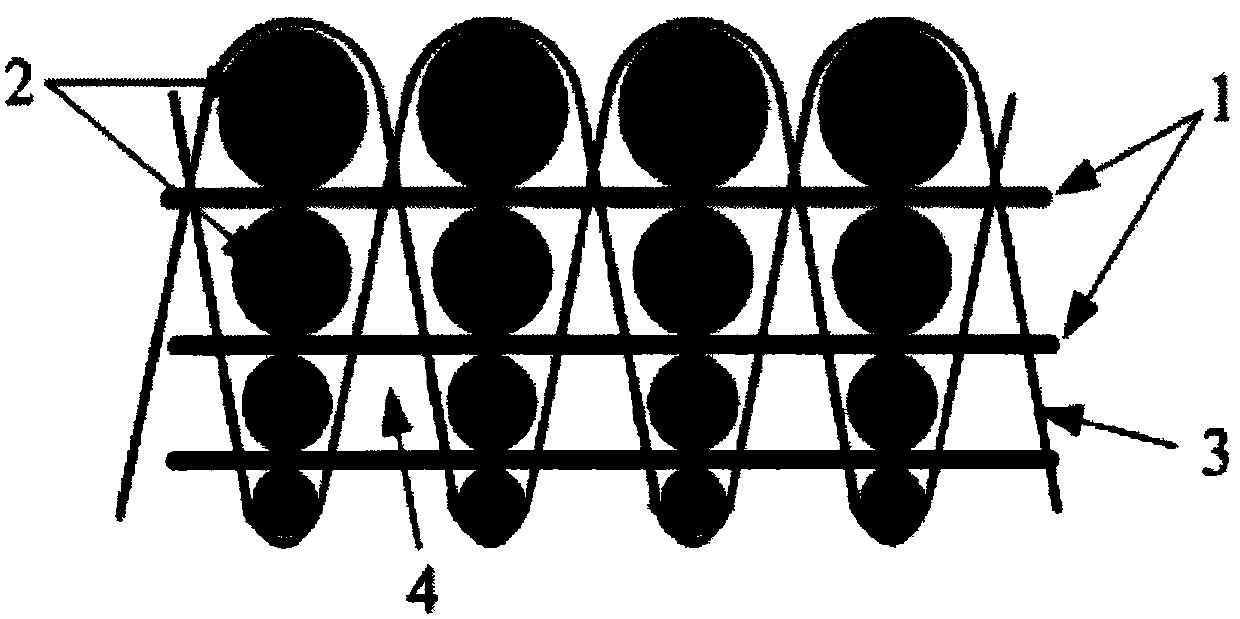

[0024] Such as figure 1 As shown, the sound-absorbing material of this embodiment is composed of warp yarn 1, weft yarn 2 and binding yarn 3. Warp yarn 1 and weft yarn 2 are perpendicular to each other and located in the same plane, and binding yarn 3 is located in a plane perpendicular to the plane where warp yarn 1 and weft yarn 2 are located. The sound-absorbing material is a three-dimensional structure containing three layers of warp yarns 1 and four layers of weft yarns 2. The thickness of each layer of weft yarns 2 decreases sequentially from top to bottom; the thickness of each layer of warp yarns 1 remains unchanged; the diameter of each layer of binding yarns 3 Keeping the same, since the thickness of each layer of weft yarn 2 decreases sequentially from top to bottom, a gradual void 4 is formed in the thickness direction of the fabric.

[0025] Select the polyester filament bulky yarn with a fineness of ...

Embodiment 2

[0032] Example 2: High Strength Fiberglass Acoustic Absorbing Fabric

[0033] Such as figure 1 As shown, the sound-absorbing material of this embodiment is composed of warp yarn 1, weft yarn 2 and binding yarn 3. Warp yarn 1 and weft yarn 2 are perpendicular to each other and located in the same plane, and binding yarn 3 is located in a plane perpendicular to the plane where warp yarn 1 and weft yarn 2 are located. The sound-absorbing material is a three-dimensional structure containing three layers of warp yarns 1 and four layers of weft yarns 2. The thickness of each layer of weft yarns 2 decreases sequentially from top to bottom; the thickness of each layer of warp yarns 1 remains unchanged; the diameter of each layer of binding yarns 3 Keeping the same, since the thickness of each layer of weft yarn 2 decreases sequentially from top to bottom, a gradual void 4 is formed in the thickness direction of the fabric.

[0034] Choose fiberglass bulked yarn with a fineness of 10...

Embodiment 3

[0041] Example 3: High Strength Fiberglass Acoustic Absorbing Composite

[0042] Step 1, adopt the method of Example 2 to prepare high-strength glass fiber acoustic wave absorbing fabric.

[0043] In step 2, the fabric obtained in step 1 is immersed in an acetone solution of epoxy resin (Guangzhou Hengyue Chemical Co., Ltd., brand: E-51) with a mass ratio concentration of 50%, and it is taken out after standing for 10 minutes.

[0044] Step 3: put it in an oven for curing, heat at 85 degrees Celsius to compound the sound-absorbing material with epoxy resin, take it out after heating for 8 hours, and obtain a composite material based on high-strength glass fiber sound-absorbing fabric. According to tests, the tensile strength of the composite material is 880MPa, which can reduce the noise intensity from 70 decibels to 47 decibels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com