Blade tip carbon fiber structure

A carbon fiber and carbon fiber cloth technology, which is applied in the field of composite material structure design, can solve the problems of separation of filler and blade body, large centrifugal force, blade damage, etc., and achieves the effect of reducing blade tip strength, processing accuracy and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is further described:

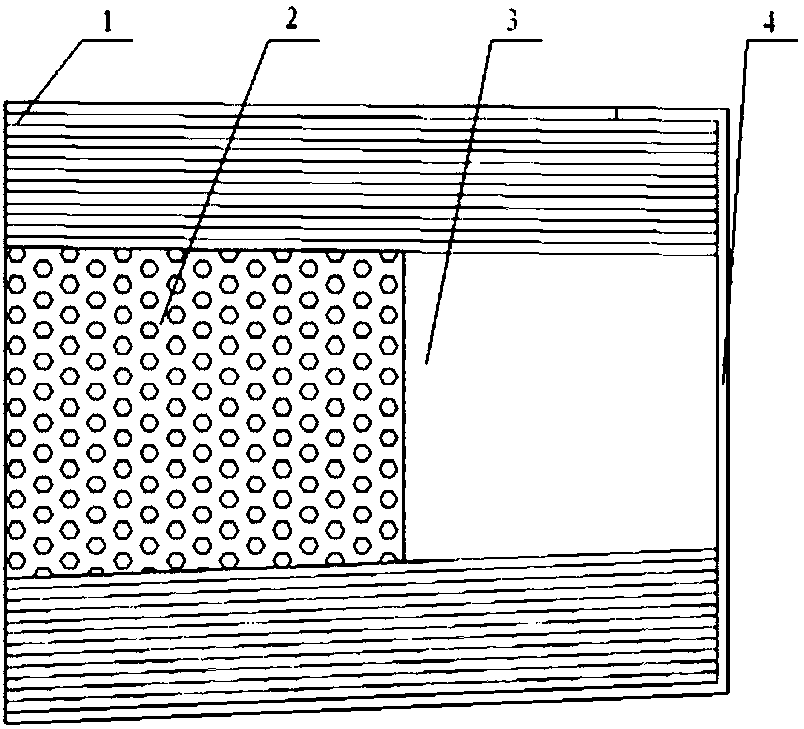

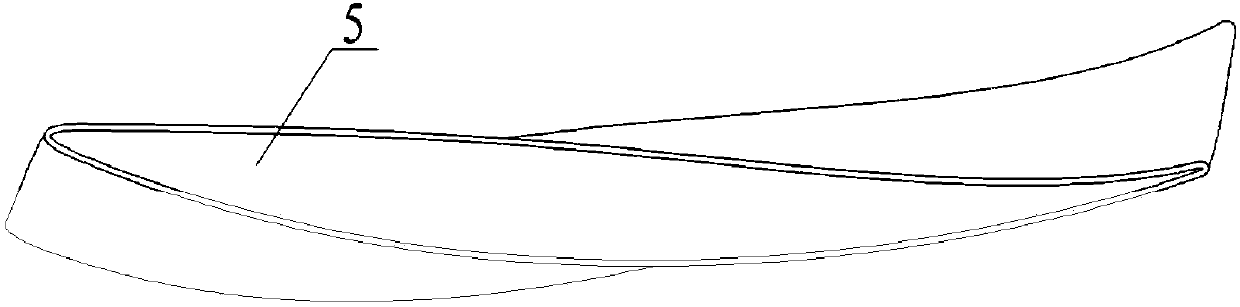

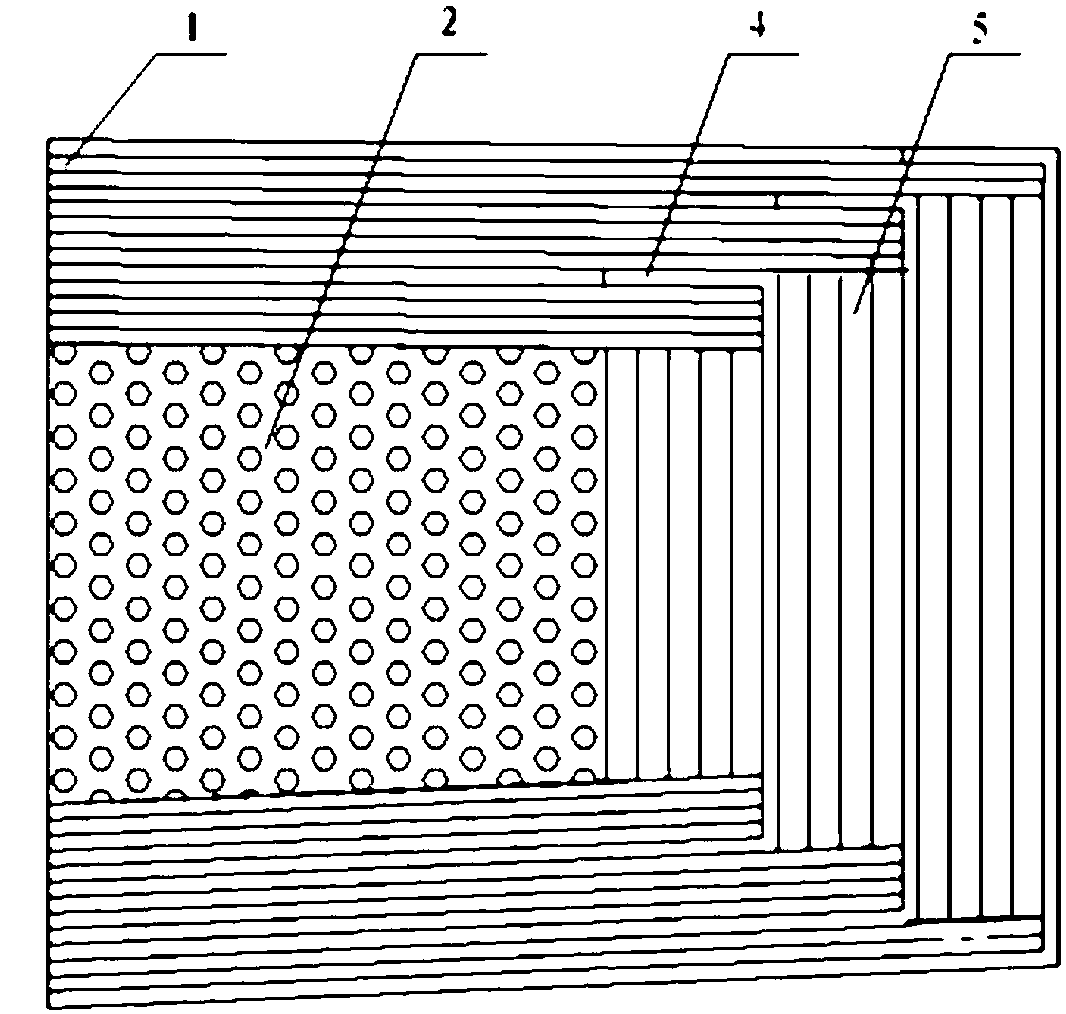

[0015] Such as figure 2 , image 3 As shown, a blade tip carbon fiber structure is firstly unloaded by a blanking machine, and the length of the outer carbon fiber cloth 1 increases sequentially from the inside to the outside, forming a ladder shape, see image 3 ; The blanking shape of the blade tip carbon fiber patch 5 is used in conjunction with the stepped shape of the outer carbon fiber cloth 1, see figure 2 ;

[0016] When laying the blade layers, ensure that the outer layer of carbon fiber cloth 1 is wrapped outside the foam 2 in a ladder shape, and fill the outer layer of carbon fiber cloth 1 into steps through the blade tip carbon fiber patch several times in 5 minutes. Pointed carbon fiber wrapping cloth 4 for wrapping, and then docking, the results are shown in image 3 .

[0017] The blade tip carbon fiber wrapping cloth 4 and the outer layer carbon fiber clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com