Large-flow intelligent pressure reducing valve integrating functions of power generation, data acquisition and automatic control and control method

A technology of data acquisition and pressure reducing valve, which is applied in the direction of hydroelectric power generation, engine components, machines/engines, etc. It can solve problems such as high cost, no detection module involved, troublesome maintenance, etc., achieve stable medium flow, and alleviate power generation instability , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

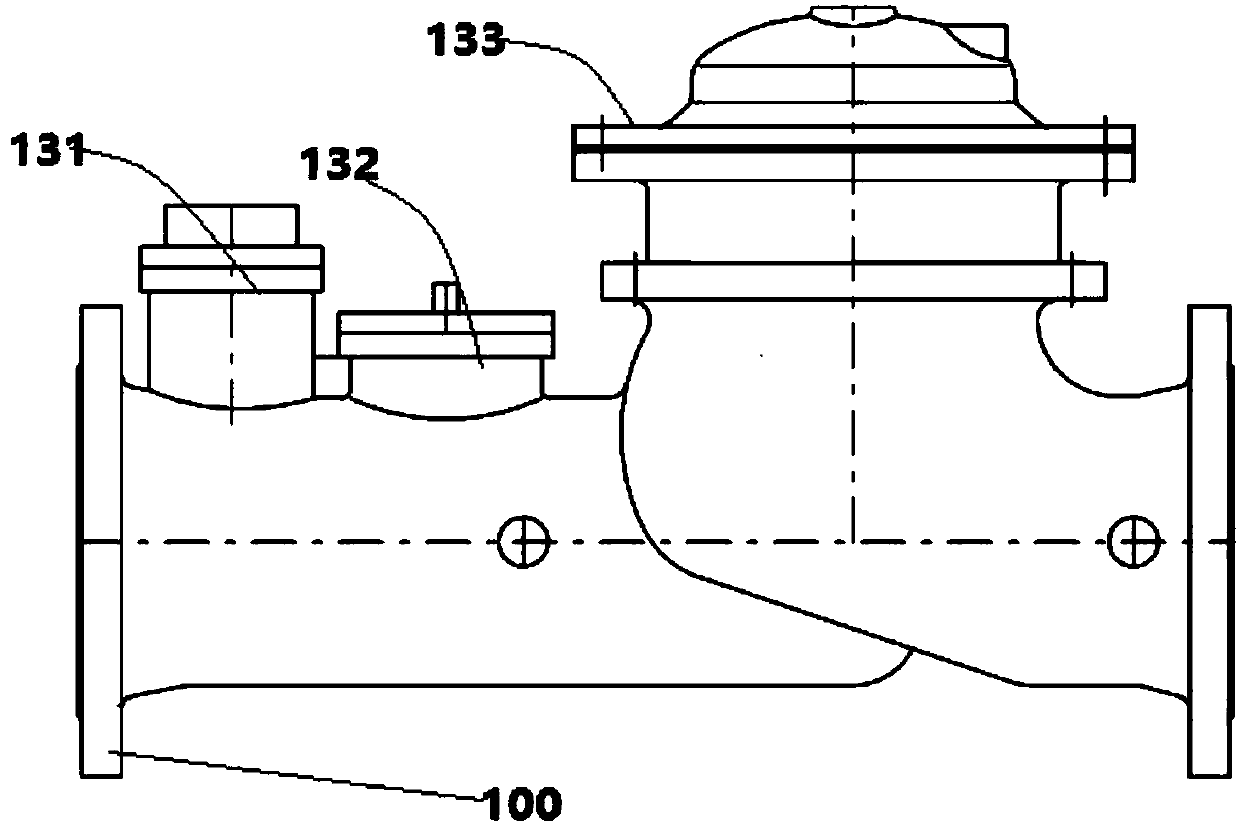

[0054] Such as figure 1 As shown, this embodiment provides a large-flow intelligent pressure reducing valve integrating power generation, data collection, and control functions. This embodiment takes a T-shaped pressure reducing valve as an example. The intelligent decompression valve includes a decompression valve body 133, a power generation device, a data acquisition component, a data processing device and a display terminal.

[0055] The data acquisition components include flowmeters, pressure sensors, and water quality sensors; in the specific implementation process, other types of data acquisition components can also be used according to specific needs, such as collecting the opening of the valve body and the temperature of the fluid. In this embodiment, the flow meter adopts an ultrasonic flow meter 131 capable of measuring the consumption of the pipe network and having a temperature compensation function. The ultrasonic flow meter 131 is arranged at the front of the i...

Embodiment 2

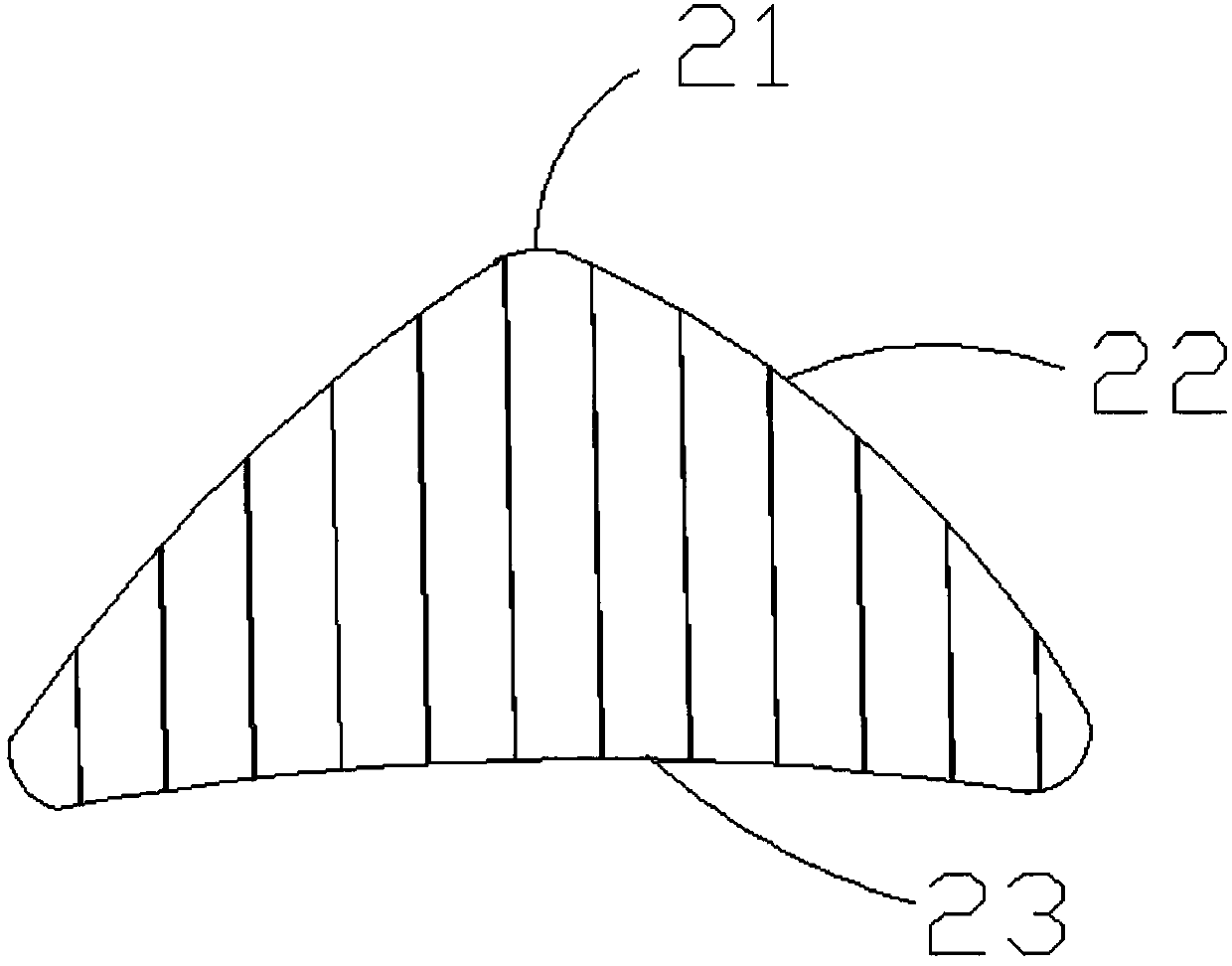

[0083] Such as Figure 5 , Image 6 , Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the intelligent pressure reducing valve in this embodiment is a Y-type intelligent pressure reducing valve; the first power generation device 132 also includes a swing mechanism; Inside, perpendicular to the flow direction. At the inlet of the pressure reducing valve, there is a guide seat 113 for guiding the fluid. The flow passes through the conical guide surface, the cylindrical guide surface and the power generation assembly in sequence, and the diameter of the cylindrical guide surface matches the size of the runner.

[0084] Such as Figure 7 As shown, the power generation assembly 109 is placed inside the pipeline, and also includes a swing mechanism that can support the vertical swing of the power generation assembly 109 relative to the axial direction of the fixed shaft 111; The valve housing is fixedly connected; the fixed shaft 111 is set in...

Embodiment 3

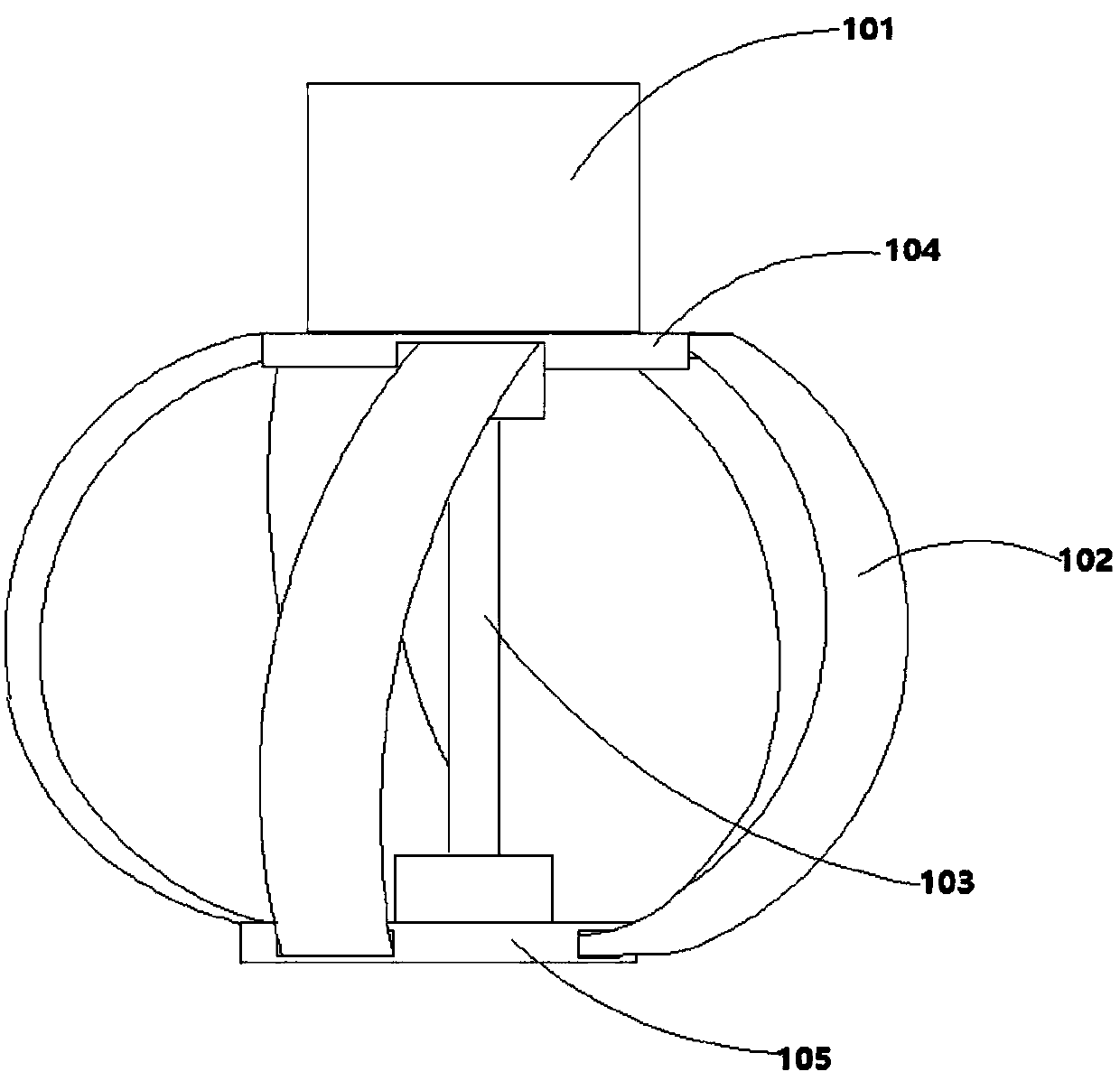

[0091] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 or Embodiment 2 is that a small runner 108 is provided inside the runner 102; the structure of the small runner 108 is consistent with that of the runner 102; The positions of the blades of the wheel 102 are staggered. The material of the small runner can be selected from light materials, so as to reduce the weight of the power generation components.

[0092] When the fluid flow rate is constant and the flow rate is normal, the small runner and the big runner rotate under the impact of the fluid, thereby driving the rotating shaft 103 to rotate. Compared with the rotation of the main shaft 3 in Embodiment 1 and Embodiment 2, Embodiment 2 increases The small runner increases the contact surface with the fluid so as to increase the thrust of the fluid on the blades and increase the rotation speed of the main shaft 3 . When the fluid flow decreases and the flow velocity decreases, the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com