Flame spread simulation experiment system

A technology for simulating experiments and flame spread, which is applied in the field of flame spread simulation experiment system, can solve the problems of insufficient rotation performance of the support system, damage to the integrity of experimental materials, and adding external heat transfer, etc., to achieve fast and convenient data recording, easy to promote and use, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

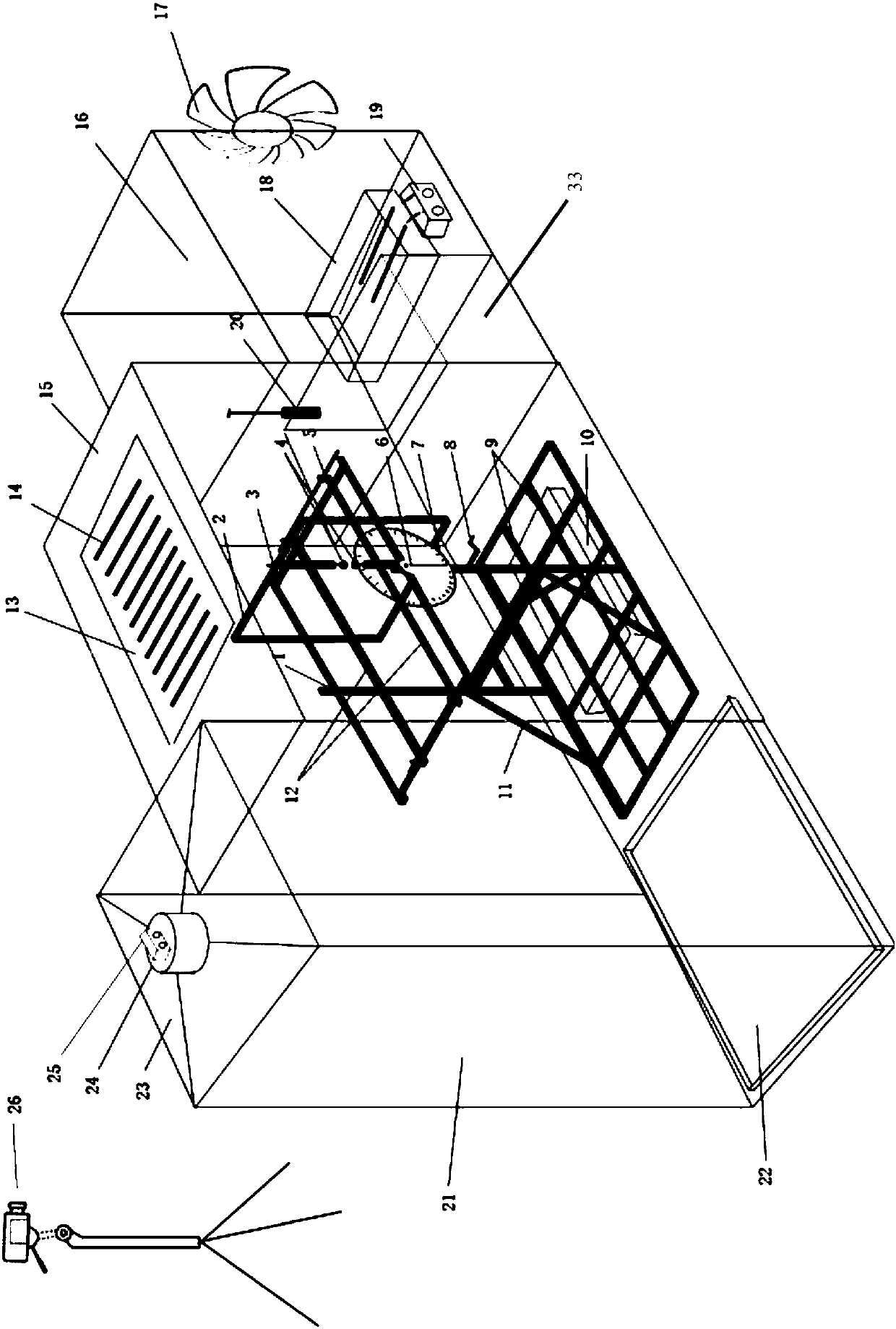

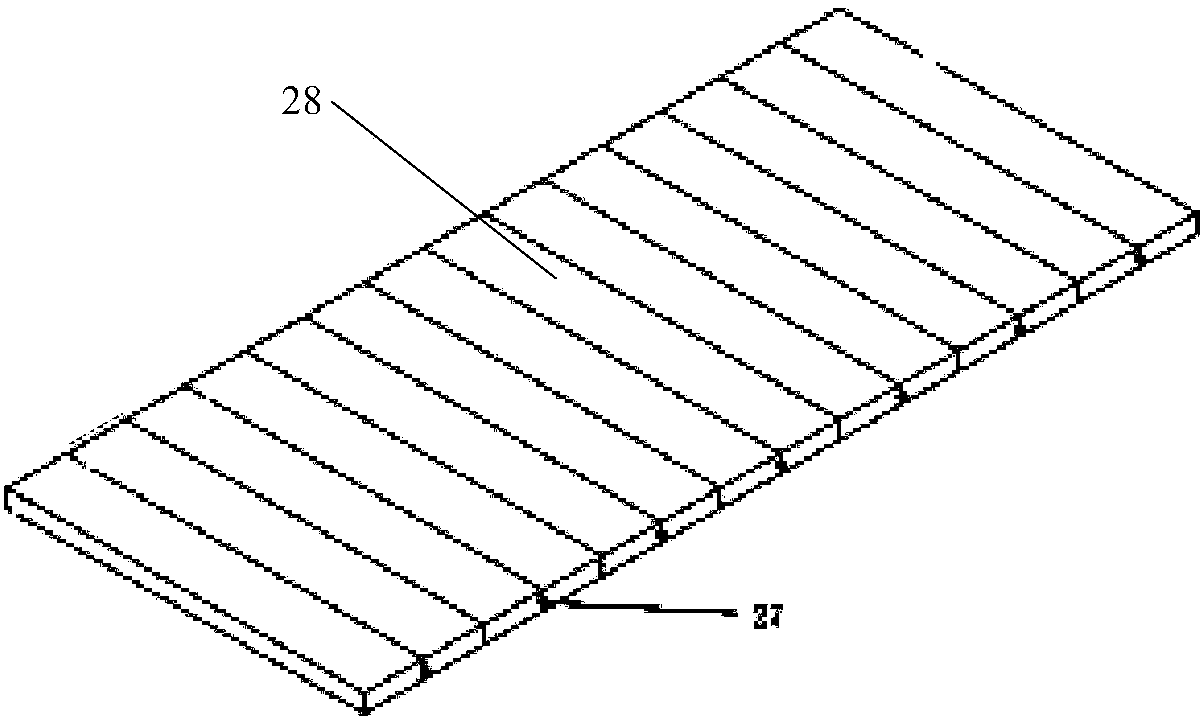

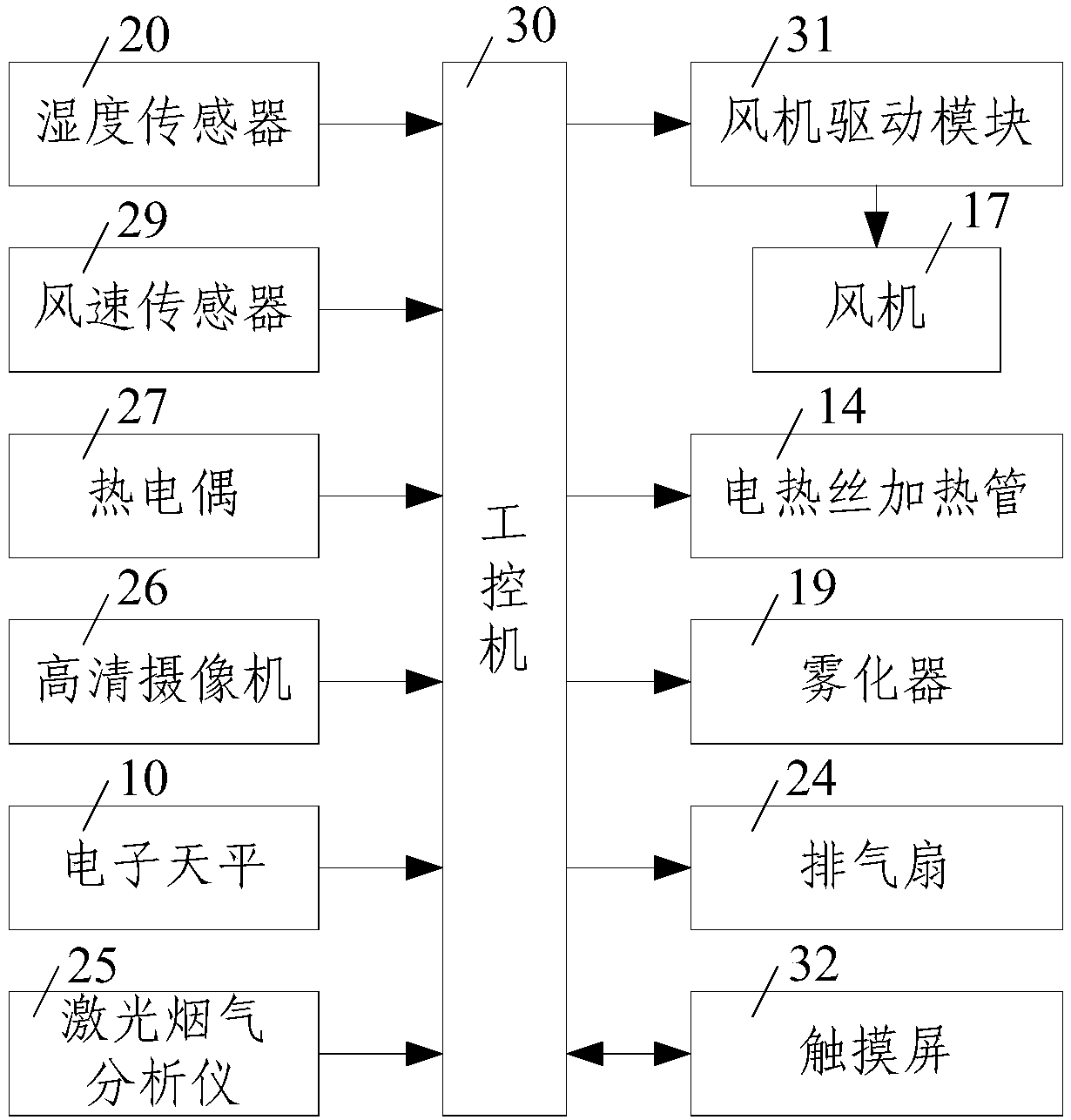

[0035] Such as figure 1 and image 3 As shown, the present invention includes a test stand for simulating the flame spread of solid combustibles 28 and a control terminal for automatically recording and controlling the work of the test stand. The test stand includes an air humidification chamber 16, a combustion chamber 15 and smoke collection chamber 21, the air humidification chamber 16 is provided with a water tank 18, an atomizer 19 extending into the water tank 18 and a humidity sensor 20 for detecting the humidity in the air humidification chamber 16, and the combustion chamber 15 A rotary support for adjusting the experimental angle of solid combustibles 28 and an electronic scale 10 arranged at the bottom of the rotary support are provided. A radiant plate 13 is provided on the top of the combustion chamber 15. An electric heating wire heating tube 14 is installed on the radiant plate 13. The smoke collection chamber 21 is provided with a smoke particle collecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com