Photovoltaic power generation system

A photovoltaic power generation system and photovoltaic module technology, applied in photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of high price and high cost of use, and achieve the goals of improving power generation efficiency, facilitating manufacturing and processing, and reducing photovoltaic voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

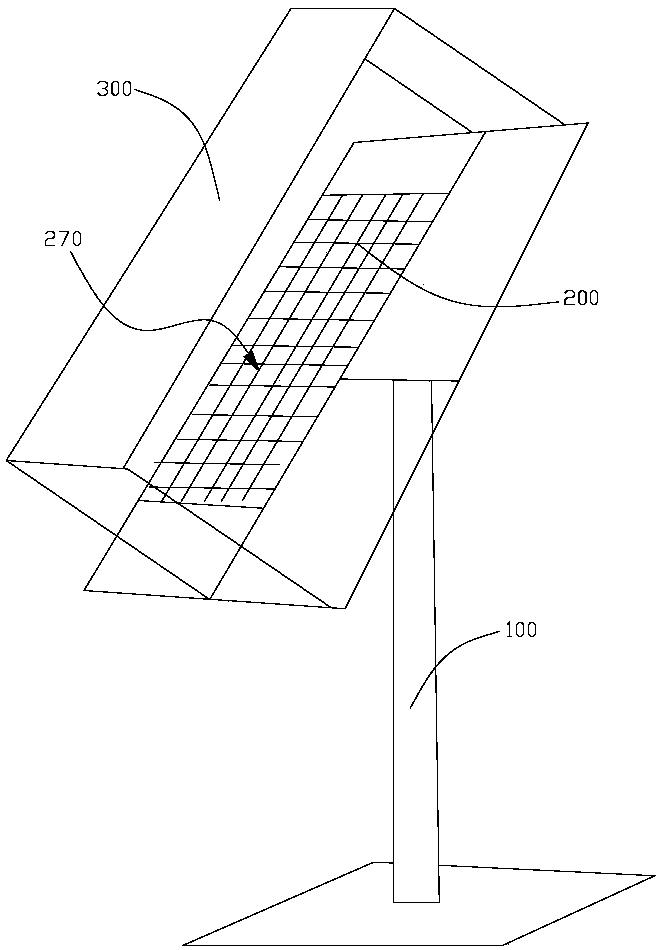

[0044] see figure 1 , this embodiment provides a photovoltaic power generation system.

[0045] The photovoltaic power generation system provided in this embodiment includes a frame 100, a photovoltaic module 200, a light-shifting component 300, and a heat-insulating and light-transmitting layer 400. The photovoltaic component 200 and the light-shifting component 300 are installed on the frame 100, and the light-shifting component 300 is set on the side where the sun-facing surface 270 of the photovoltaic module 200 is located, and the heat-insulating and light-transmitting layer 400 is set on the side where the sun-facing surface of the photovoltaic module 200 is located. The cells for photovoltaic electronic components can reduce the photovoltaic voltage of photovoltaic components.

[0046] In other words, the photovoltaic power generation system provided in this embodiment is a low-temperature high-light photovoltaic power generation system, and the low-temperature high-li...

Embodiment 2

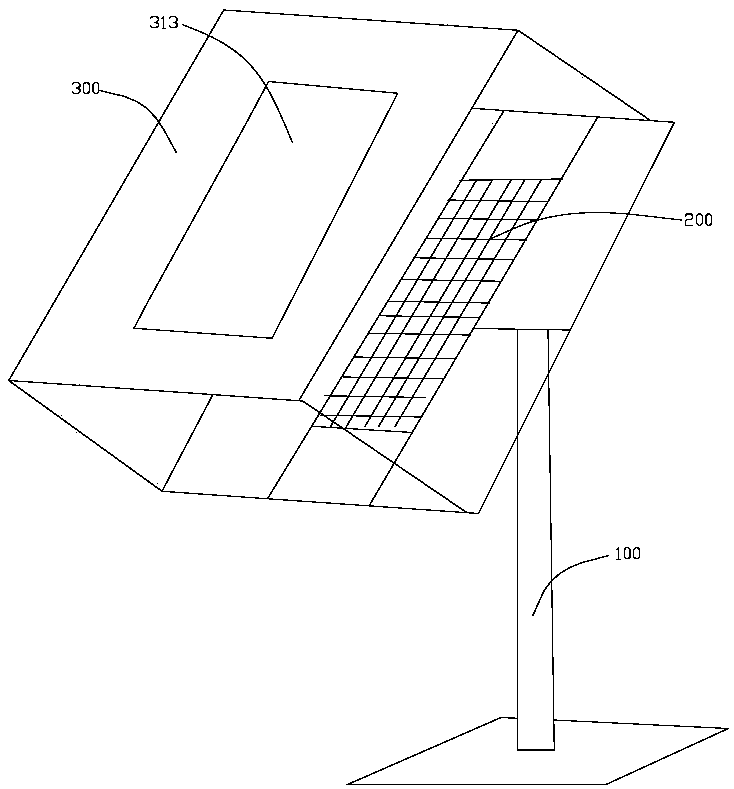

[0063] see Figure 4 , this embodiment also provides a photovoltaic power generation system, this embodiment is a further improvement on the basis of the technical solution of embodiment 1, the technical solution already described in embodiment 1 is also applicable to this embodiment, in order to avoid The description is redundant, and the technical solution disclosed in Embodiment 1 will not be described in detail again.

[0064] see Figure 8 - Figure 9 , in this embodiment, the heat-insulating and light-transmitting layer 400 is installed on the dust-removing glass 260, and the heat-insulating and light-transmitting layer 400 can be painted on the outer surface or the inner surface of the dust-removing glass 260, or the heat-insulating and light-transmitting layer 400 can be directly It is integrally formed with the dust-removing glass, and the material for making the heat-insulating light-transmitting layer 400 and the material of the dust-removing glass are mixed and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com