Automatic cleaning device for barren mountain photovoltaic power station assembly

A photovoltaic power station, automatic cleaning technology, applied in photovoltaic power generation, photovoltaic modules, electrical components and other directions, can solve the problem of inability to adapt to the scattered installation of photovoltaic power stations in barren hills, and achieve the effect of saving manpower and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

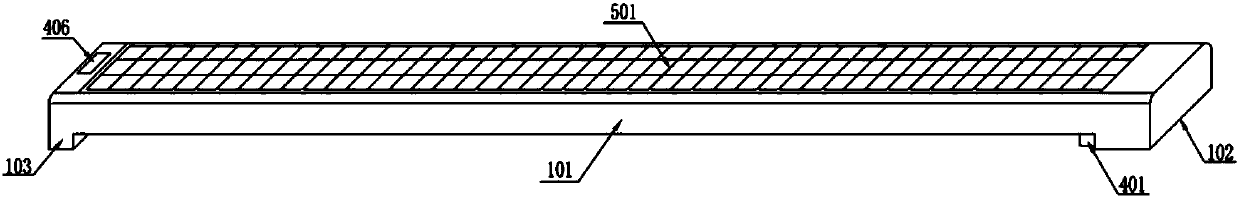

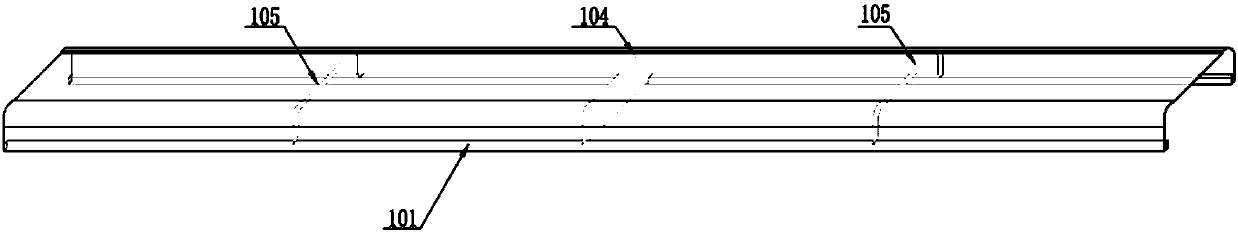

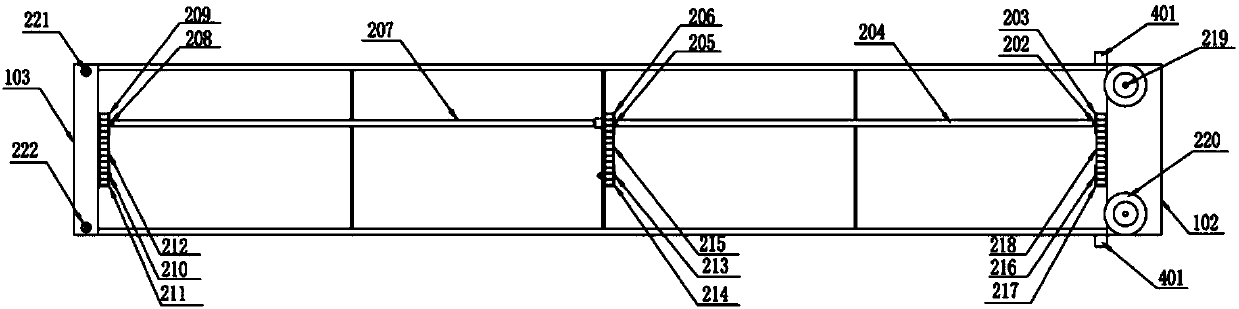

[0050] Such as Figure 1-6 As shown, the present invention includes: a cleaning part connected with the housing 1; the cleaning part includes an electromechanical automatic part and an automatic control part, and the electromechanical automatic part includes a walking part 2 and a cleaning part 3, which are cleaning functions. The mechanical implementation part; the automatic control part includes a processing part 4, a power supply part 5, and the processing part 4 is respectively connected with the walking part 2, the cleaning part 3, and the housing 1 for automatic control of the cleaning part; the walking part 2; The cleaning part 3 is connected with the housing 1 and adjusts its rotation direction at any time; the power supply part 5 distributes the required voltage and power to the walki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com