Thermal forming device

A thermoforming and accommodating groove technology, applied in the field of machining, can solve the problems of shortening the service life of the mold, damage to the punch insert, and rising production costs, so as to improve the product yield, prolong the service life, and achieve consistent tensile strength. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

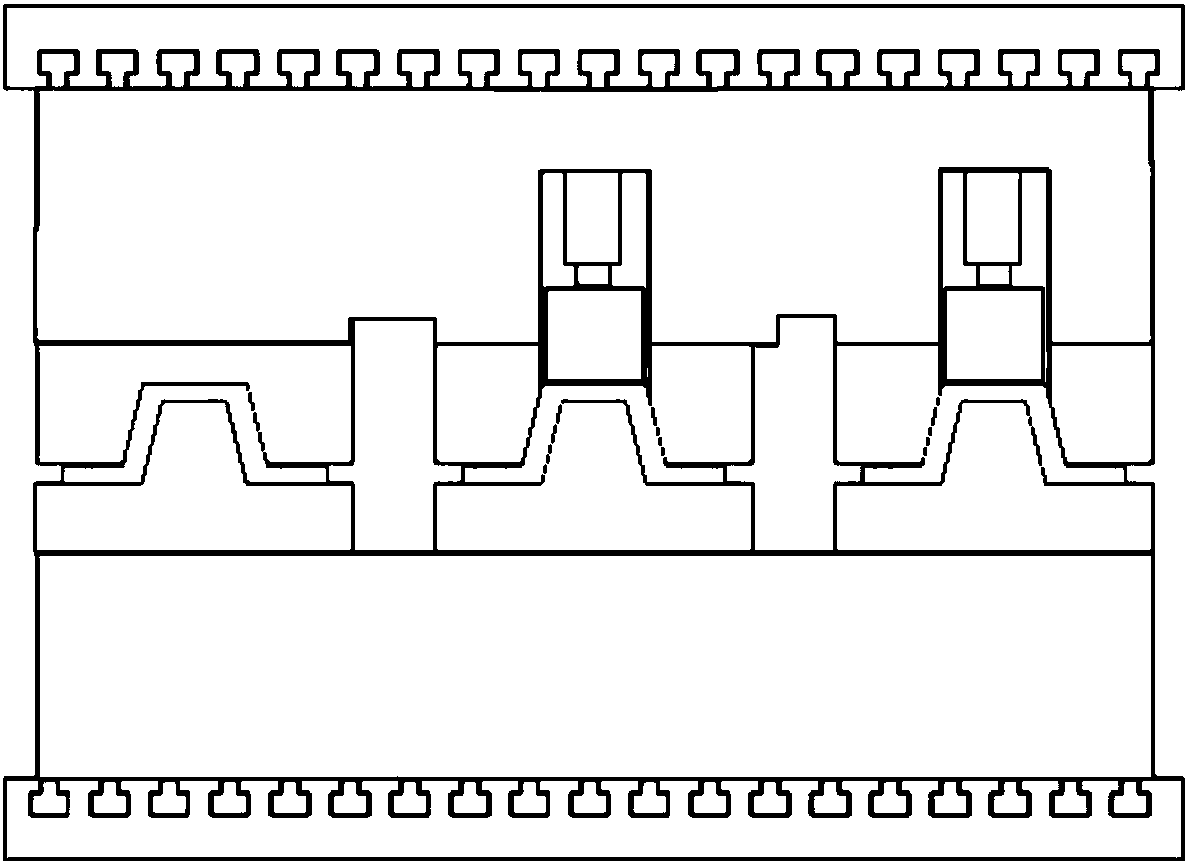

[0044] This embodiment provides a thermoforming device, such as Figure 5 As shown, the device 2 includes a first substrate 1, a second substrate 3, and a plurality of molds 2 arranged between the first substrate 1 and the second substrate 3. See Image 6 Each mold 2 includes an upper mold 21 and a lower mold 23 that cooperate with each other. The upper mold 21 includes an upper mold base 211 and an upper mold body. The lower mold 23 includes a lower mold base 231 and a lower mold body. The mold base 211 is mounted on the first substrate 1, the top of the upper mold 21 body is connected to the upper mold base 211, the lower mold base 231 is mounted on the second base plate 3, and the lower mold The bottom of the body is connected to the lower mold base 231, and a cavity for accommodating the workpiece 22 is formed between the bottom of the upper mold 21 and the top of the lower mold 23; the upper mold body and the upper mold base 211 is fixedly connected, the lower mold body ha...

Embodiment 2

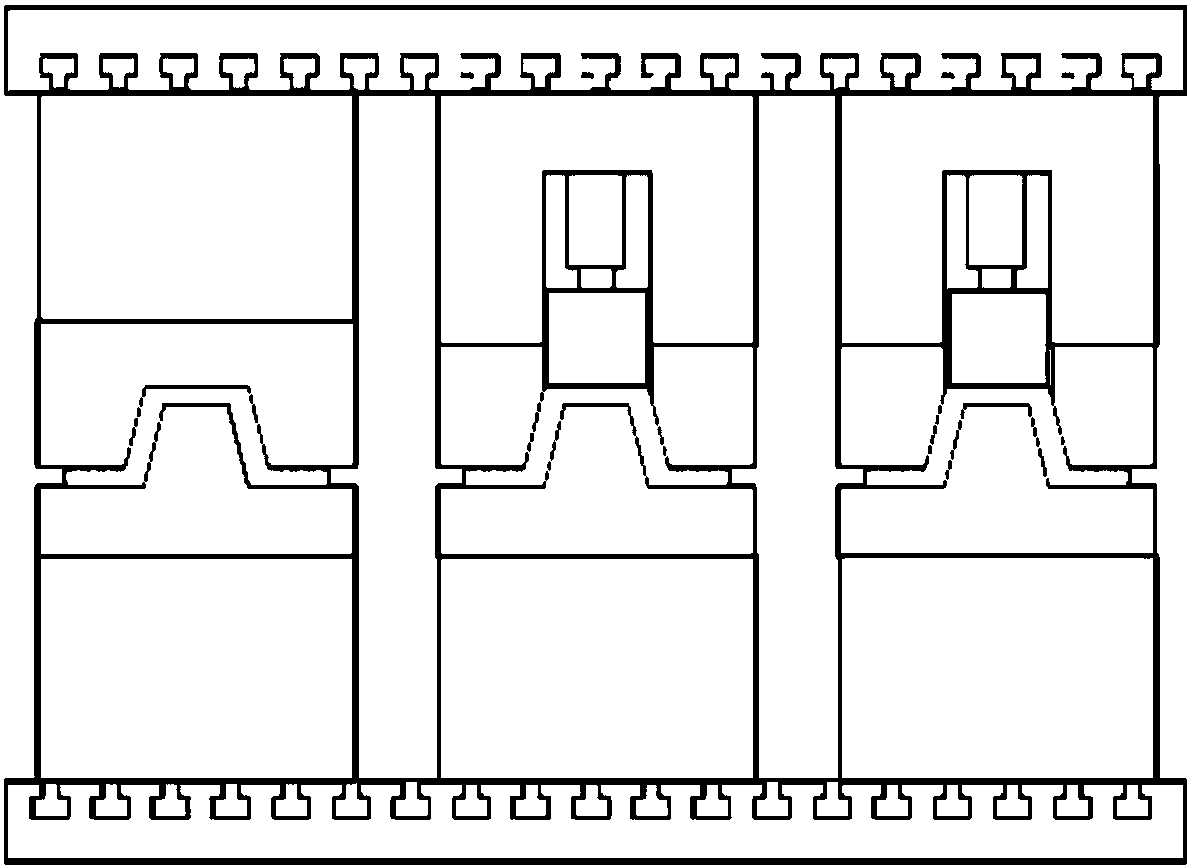

[0057] This embodiment provides a thermoforming device, such as Figure 7 As shown, the device 2 includes a first substrate 1, a second substrate 3, and a plurality of molds 2 arranged between the first substrate 1 and the second substrate 3. See Image 6 Each mold 2 includes an upper mold 21 and a lower mold 23 that cooperate with each other. The upper mold 21 includes an upper mold base 211 and an upper mold body. The lower mold 23 includes a lower mold base 231 and a lower mold body. The mold base 211 is mounted on the first substrate 1, the top of the upper mold 21 body is connected to the upper mold base 211, the lower mold base 231 is mounted on the second base plate 3, and the lower mold The bottom of the body is connected to the lower mold base 231, and a cavity for accommodating the workpiece 22 is formed between the bottom of the upper mold 21 and the top of the lower mold 23; the lower mold body and the lower mold base 231 is fixedly connected, the upper mold body ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com