A thermoplastic resin composite sheet production device and process

A thermoplastic resin, composite sheet technology, used in lamination devices, layered products, single-component synthetic polymer rayon, etc., can solve the problems of loose bonding between layers, loss of functional type, and different curing shrinkage rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

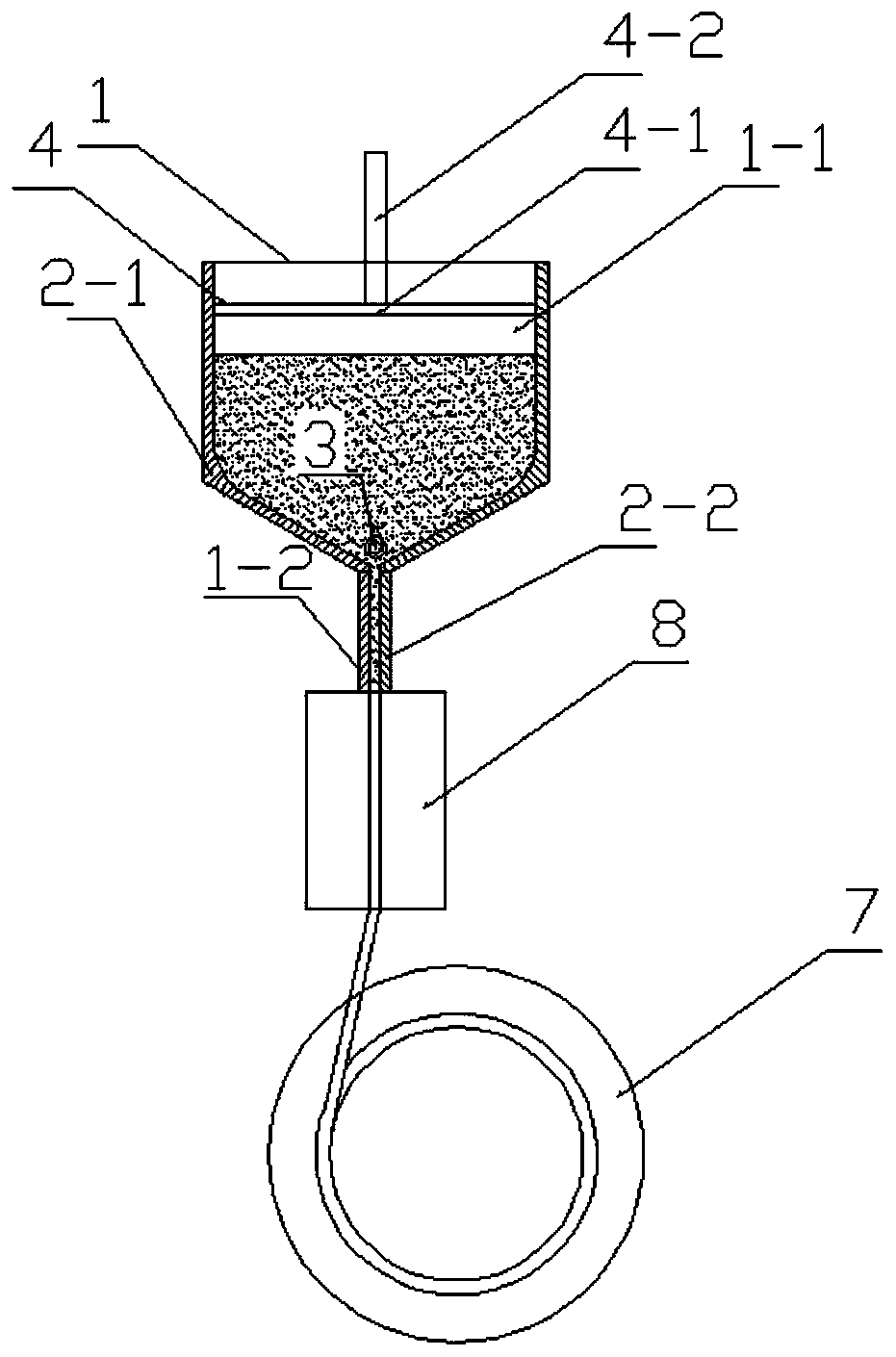

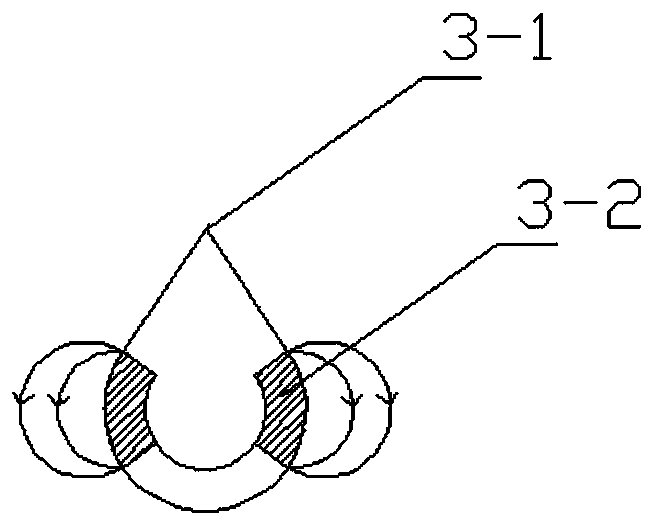

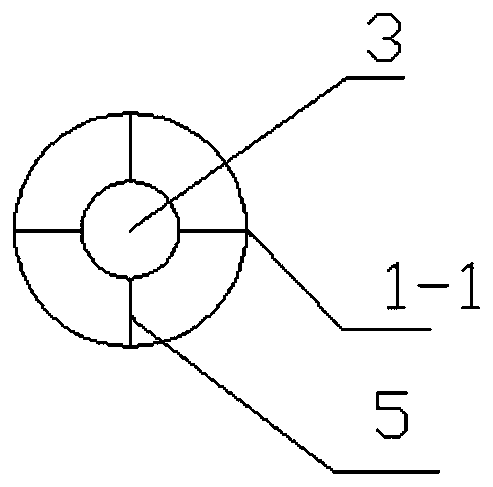

[0066] A fiber manufacturing process is a melt spinning process, and the melt is obtained as follows:

[0067] Step 1, at 50°C, the α-Al 2 o 3 Place the nanoparticles in an aluminum sulfate solution with a concentration of 0.5mol / L to obtain a dispersion, and adjust the pH of the solution to 6-7; add magnetic material particles (Fe particles, with an average particle size of 2 microns) to the dispersion, and after adding, Add ammonium bicarbonate solution with a concentration of 1.5mol / L dropwise into it, the volume of the aluminum salt solution and the ammonium bicarbonate solution is 1:1; then the resulting mixture is spray-dried, and the dried particles are roasted, The calcination temperature is 450°C to obtain α-Al 2 o 3 coated magnetic material particles, wherein, α-Al 2 o 3 The ratio of nanoparticles to inorganic aluminum salt solution is 1g:500mL;

[0068] Step two, polyphenylene sulfide powder, step one obtained α-Al 2 o 3 After mixing the coated magnetic mate...

Embodiment 2

[0071] A fiber manufacturing process is a melt spinning process, and the melt is obtained as follows:

[0072] Step 1, at 50°C, the α-Al 2 o 3 Place the nanoparticles in an aluminum sulfate solution with a concentration of 0.5mol / L to obtain a dispersion, and adjust the pH of the solution to 6-7; add magnetic material particles (Fe particles, with an average particle size of 2 microns) to the dispersion, and after adding, Add ammonium bicarbonate solution with a concentration of 1.5mol / L dropwise into it, the volume of the aluminum salt solution and the ammonium bicarbonate solution is 1:1; then the resulting mixture is spray-dried, and the dried particles are roasted, The calcination temperature is 450°C to obtain α-Al 2 o 3 coated magnetic material particles, wherein, α-Al 2 o 3 The ratio of nanoparticles to inorganic aluminum salt solution is 1g:500mL;

[0073] Step two, polyphenylene sulfide powder, step one obtained α-Al 2 o 3 The coated magnetic material particle...

Embodiment 3

[0076] A fiber manufacturing process is a melt spinning process, and the melt is obtained as follows:

[0077] Step 1, at 80°C, the α-Al 2 o 3The nanoparticles are placed in the inorganic aluminum salt solution with a concentration of 1mol / L to obtain a dispersion, and the pH of the solution is adjusted to 6-7; the magnetic material particles are added to the dispersion, and the concentration of 2mol / L is added dropwise to the dispersion. L of ammonium bicarbonate solution, the volume of the aluminum salt solution and the ammonium bicarbonate solution is 1:1; then the resulting mixture is spray-dried, and the dried particles are roasted at a roasting temperature of 500°C to obtain α-Al 2 o 3 coated magnetic material particles, wherein, α-Al 2 o 3 The ratio of nanoparticles to inorganic aluminum salt solution is 1g:700mL;

[0078] Step two, the α-Al obtained in step one 2 o 3 The coated magnetic material particles are mixed with other fiber raw materials and obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com