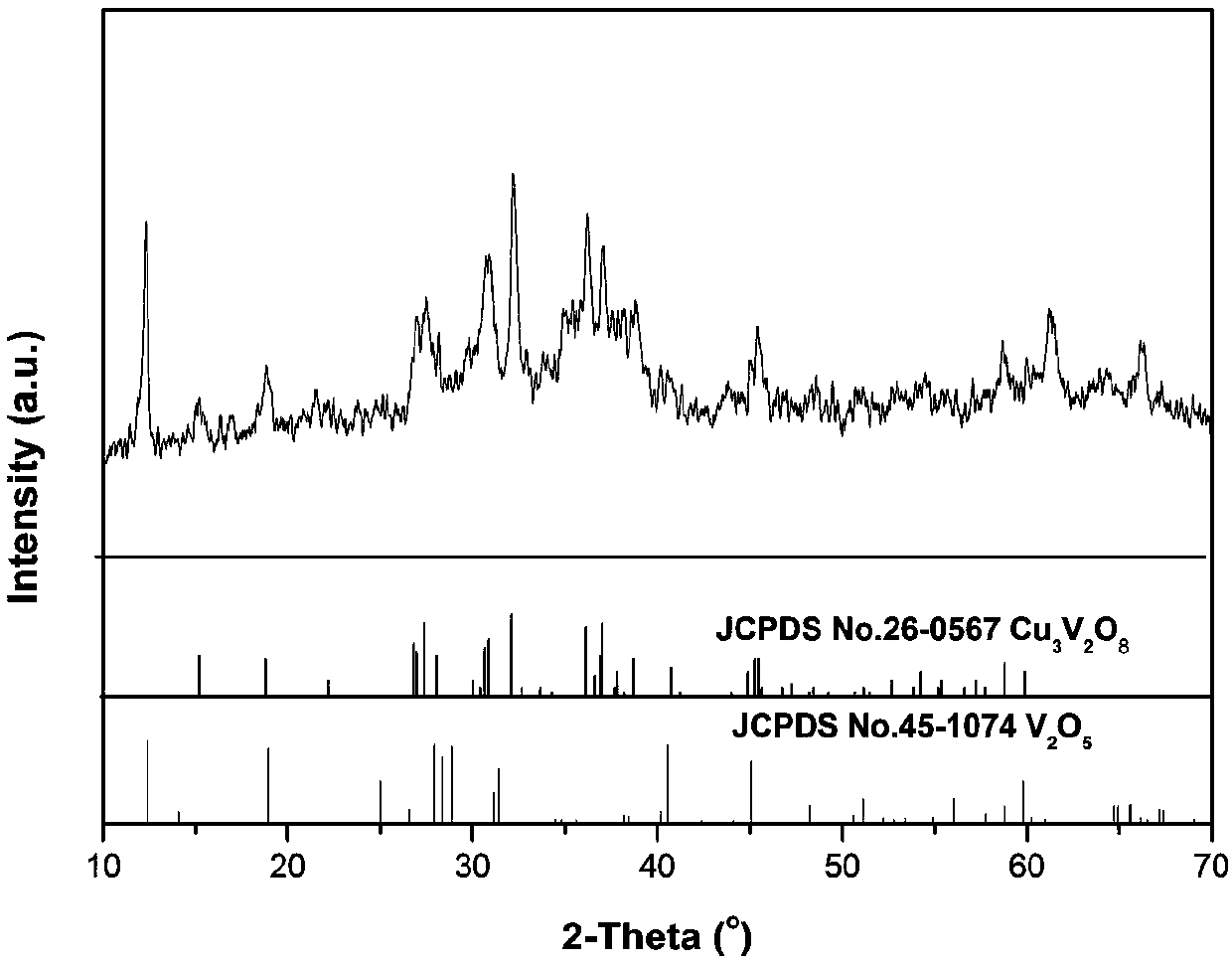

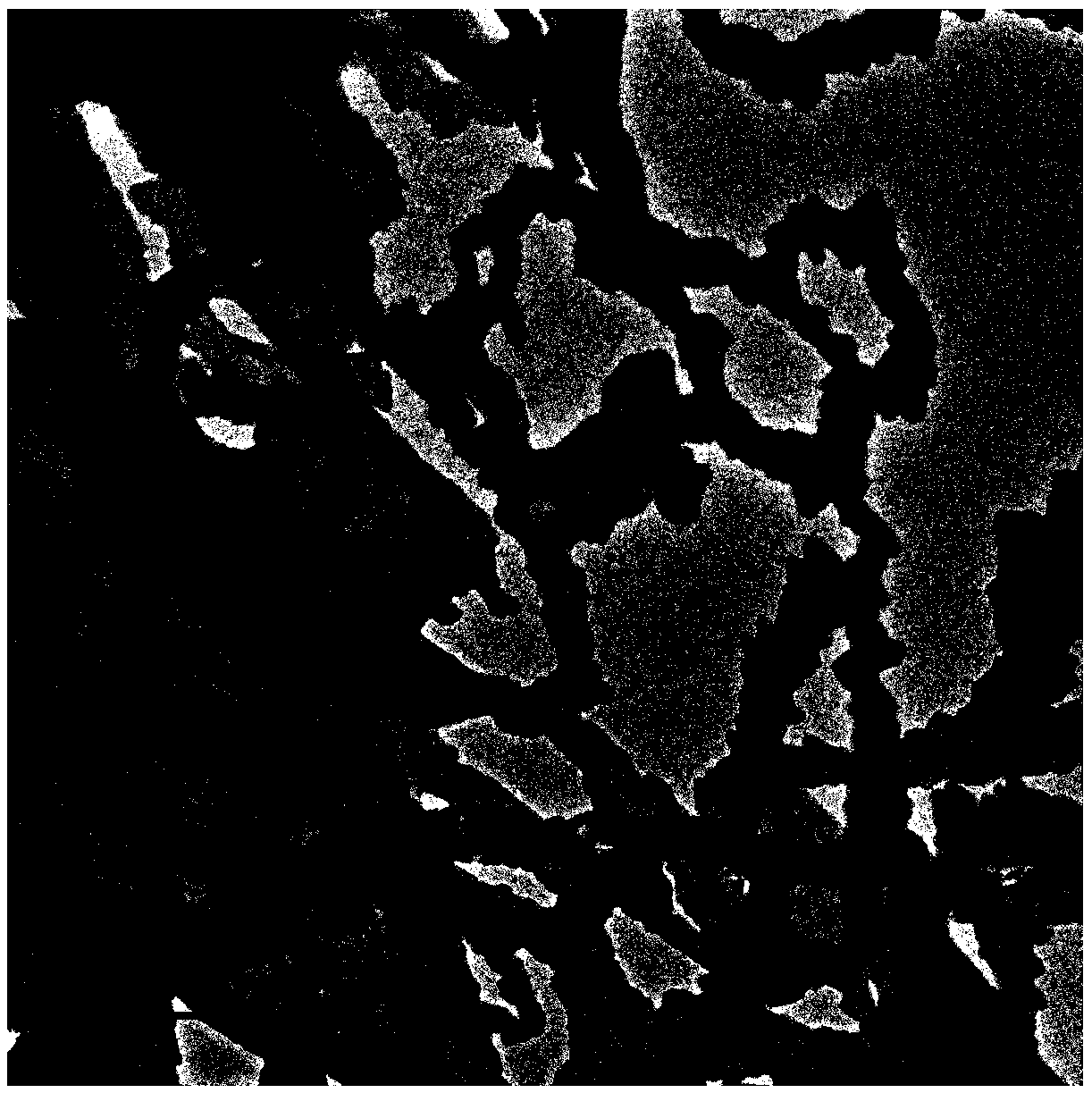

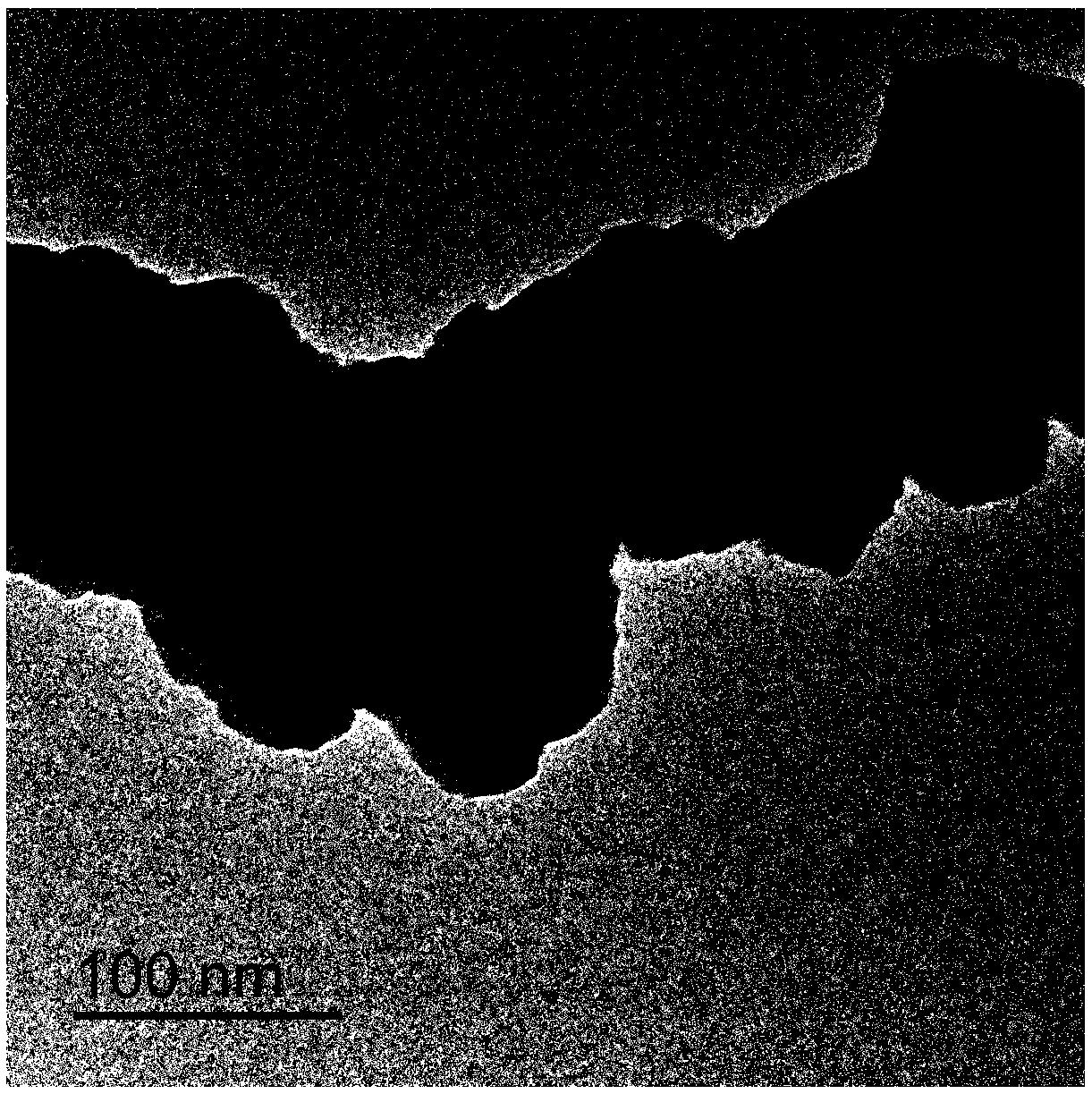

Preparation method of nanowire-like Cu3V2O8-V2O5 composite powder

A technology of cu3v2o8-v2o5 and composite powder, which is applied in the direction of chemical instruments and methods, vanadium compounds, vanadium oxide, etc., can solve the problems of high preparation cost, non-compliance with environmental protection, dangerous reaction process, etc. The effect of short cycle time and excellent lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) According to the solid-liquid ratio of 0.1g:50mL, Cu 3 V 2 o 8 Dispersed to a concentration of 0.1mol / L AgNO 3 Dispersion in solution;

[0024] 2) Pass nitrogen into the dispersion to continue bubbling, wherein the nitrogen flow rate is 10 sccm, and the bubbling time is 30 minutes;

[0025] 3) Pour the dispersion into a quartz tube, irradiate it with a 100W mercury lamp, keep stirring for 5 hours, wash it alternately with deionized water and absolute ethanol after centrifugal separation, and dry the washed product at 60°C to obtain nanowire-shaped Cu 3 V 2 o 8 -V 2 o 5 Composite powder.

Embodiment 2

[0027] 1) According to the solid-liquid ratio of 0.1g:100mL, Cu 3 V 2 o 8 Dispersed to a concentration of 0.5mol / L AgNO 3 Dispersion in solution;

[0028] 2) Pass nitrogen into the dispersion to continue bubbling, wherein the nitrogen flow rate is 20 sccm, and the bubbling time is 30 minutes;

[0029] 3) Pour the dispersion into a quartz tube, irradiate it with a 300W mercury lamp, keep stirring for 3 hours, wash it alternately with deionized water and absolute ethanol after centrifugation, and dry the washed product at 80°C to obtain nanowire-shaped Cu 3 V 2 o 8 -V 2 o 5 Composite powder.

Embodiment 3

[0031] 1) According to the solid-liquid ratio of 0.1g:150mL, Cu 3 V 2 o 8 Dispersed to a concentration of 1mol / L AgNO 3 Dispersion in solution;

[0032] 2) Introduce nitrogen into the dispersion for continuous bubbling, wherein the nitrogen flow rate is 50 sccm, and the bubbling time is 30 minutes;

[0033] 3) Pour the dispersion liquid into a quartz tube, irradiate it with a 1000W mercury lamp, keep stirring for 0.5h, separate it by suction filtration, wash it alternately with deionized water and absolute ethanol, and dry the washed product at 40°C to obtain nanowires Cu-like 3 V 2 o 8 -V 2 o 5 Composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com