Aluminum alloy variable chamber particle collision damper for pipeline vibration reduction

A particle collision, aluminum alloy technology, applied in the direction of shock absorber, friction shock absorber, shock absorber, etc., can solve the problems of poor vibration control effect, limited installation conditions, large mass, etc., and achieve a significant effect of vibration reduction , small installation space and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

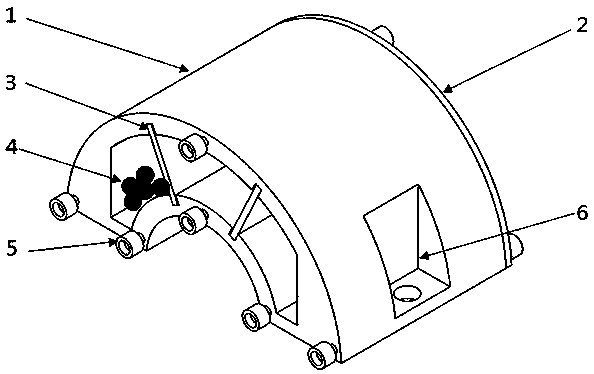

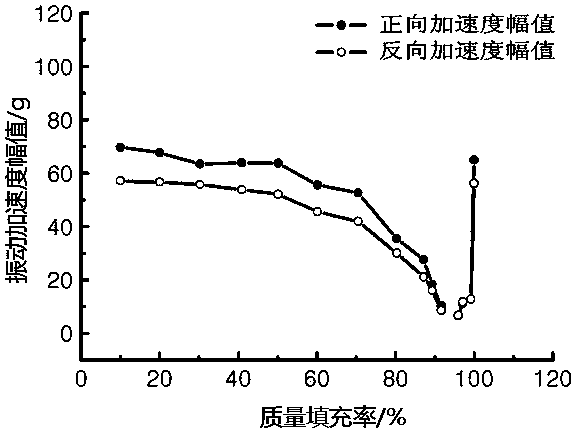

[0022] An aluminum alloy variable-chamber particle collision damper for pipeline vibration reduction includes a pair of semi-circular column cavities 1, and each semi-circular cavity is provided with a semi-circular outer surface at both ends of the cavity. Cover plate 2, the inside of the semi-annular column cavity 1 is provided with a plurality of cavity internal unit partitions 3, and the interior of the semi-annular column cavity 1 is divided into a plurality of cavity internal unit partitions 3 An independent small cavity filled with metal particles 4 . The metal particles 4 inside the cavity will collide and rub against each other as the pipeline vibrates, thus consuming the vibration energy of the system. The filling rate of the metal particles 4 inside the cavity is the main factor affecting the vibration damping effect of the pipeline. The patented invention has simple structure, small installation space and remarkable vibration reduction effect.

Embodiment 2

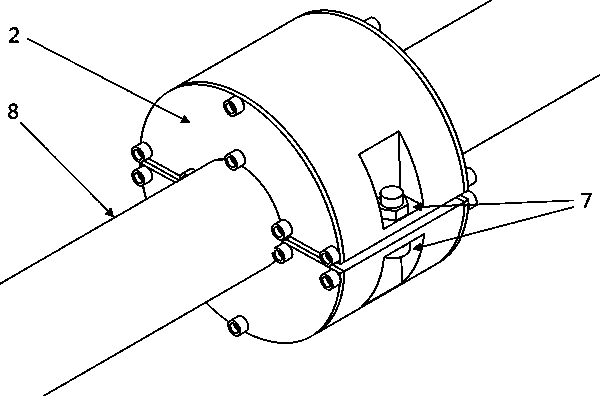

[0024] An aluminum alloy variable-chamber particle collision damper for pipeline vibration reduction includes a pair of semi-circular column cavities 1, and each semi-circular cavity is provided with a semi-circular outer surface at both ends of the cavity. Cover plate 2, the inside of the semi-annular column cavity 1 is provided with a plurality of cavity internal unit partitions 3, and the interior of the semi-annular column cavity 1 is divided into a plurality of cavity internal unit partitions 3 An independent small cavity filled with metal particles 4 . The cover plate 2 on the outer surface of the cavity is fixed on the end surface of the cavity 1 of the semicircular column by a plurality of first bolts 5 . The edge of a pair of semi-annular column chambers 1 is provided with a cylinder groove 6, and a through hole is provided on the bottom of the cylinder groove 6, and the two semi-annular column chambers 1 pass through the second bolt and the through hole. The nuts 7 ...

Embodiment 3

[0028] Such as figure 1 As shown, the patent of the present invention relates to a pipeline damper based on particle collision damping technology that suppresses pipeline vibration, and belongs to the field of vibration control technology. The pipeline damper is made of aluminum alloy as a whole, and includes a pair of semi-circular column cavities 1 , a cover plate 2 on the outer surface of the cavity, a unit partition 3 inside the cavity and internal metal particles 4 . Fill the interior of the semi-annular column cavity 1 with a certain amount of metal particles 4, fix the semi-circular thin plate to close the cavity by the first bolt 5, and a pair of semi-annular column cavity 1 filled with metal particles 4 pass through the groove of the column body The second bolt and nut 7 in 6 are fastened on the vibrating pipeline 8 . The metal particles 4 inside the cavity will collide and rub against each other as the pipeline vibrates, thus consuming the vibration energy of the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com