Environment-friendly continuous oil sludge treatment process

A technology for environmental protection treatment and oil sludge, applied in incinerators, combustion methods, lighting and heating equipment, etc., can solve problems such as environmental pollution, insufficient oil sludge treatment, unfavorable environmental sustainable development, etc., to prevent environmental pollution and eliminate pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

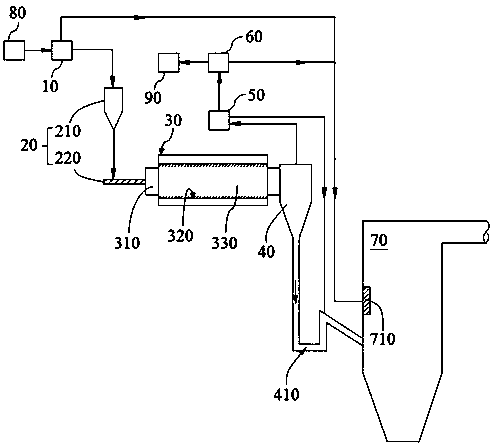

[0038] see image 3 , a continuous oil sludge environmental protection treatment process, comprising the following steps:

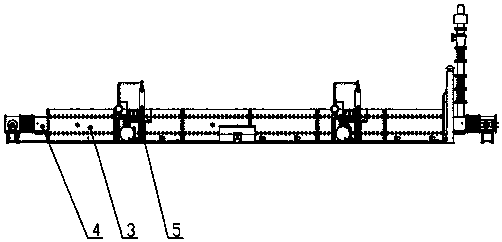

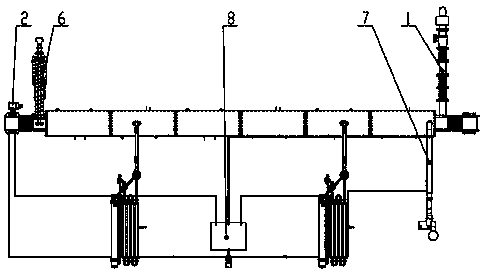

[0039] S1. Measuring and feeding. Put the prepared materials into the buffer bin with the loader. The materials are in the buffer bin. The feeding amount is controlled by the electromagnetic vibrating feeder, and they are continuously sent to the belt scale for metering. The material is sent into the buffer silo through the belt conveyor, the material passes through the buffer silo, and enters the closed dehydration drying furnace through the sealed continuous distribution equipment.

[0040] S2. Drying in the drying furnace. Under the action of two screw feeders, the oil sludge entering the drying furnace evenly passes through the preheating zone, drying zone and high temperature zone set in the drying furnace, and initially enters the drying furnace The sludge is preheated and heated in the preheating zone at the front of the furnace to remove moisture...

Embodiment 2

[0045] S1. Measuring and feeding. Put the prepared materials into the buffer bin with the loader. The materials are in the buffer bin. The feeding amount is controlled by the electromagnetic vibrating feeder, and they are continuously sent to the belt scale for metering. The material is sent into the buffer silo through the belt conveyor, the material passes through the buffer silo, and enters the closed dehydration drying furnace through the sealed continuous distribution equipment.

[0046] S2. Drying in the drying furnace. Under the action of two screw feeders, the oil sludge entering the drying furnace evenly passes through the preheating zone, drying zone and high temperature zone set in the drying furnace, and initially enters the drying furnace The sludge is preheated and heated in the preheating zone at the front of the furnace to remove moisture and humid gas on the surface of the sludge. The temperature of the sludge continues to rise during the process of moving forw...

Embodiment 3

[0052] A continuous oil sludge environmental protection treatment process, comprising the following steps:

[0053] S1. Measuring and feeding. Put the prepared materials into the buffer bin with the loader. The materials are in the buffer bin. The feeding amount is controlled by the electromagnetic vibrating feeder, and they are continuously sent to the belt scale for metering. The material is sent into the buffer silo through the belt conveyor, the material passes through the buffer silo, and enters the closed dehydration drying furnace through the sealed continuous distribution equipment.

[0054] S2. Drying in the drying furnace. Under the action of two screw feeders, the oil sludge entering the drying furnace evenly passes through the preheating zone, drying zone and high temperature zone set in the drying furnace, and initially enters the drying furnace The sludge is preheated and heated in the preheating zone at the front of the furnace to remove moisture and humid gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com