High-precision contact type auxiliary test jig and work method thereof

An auxiliary testing and high-precision technology, which is applied in the direction of electronic circuit testing, measuring electronics, measuring devices, etc., can solve problems such as audio CCD capture position accuracy, achieve the effect of avoiding reflection problems, reasonable design, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

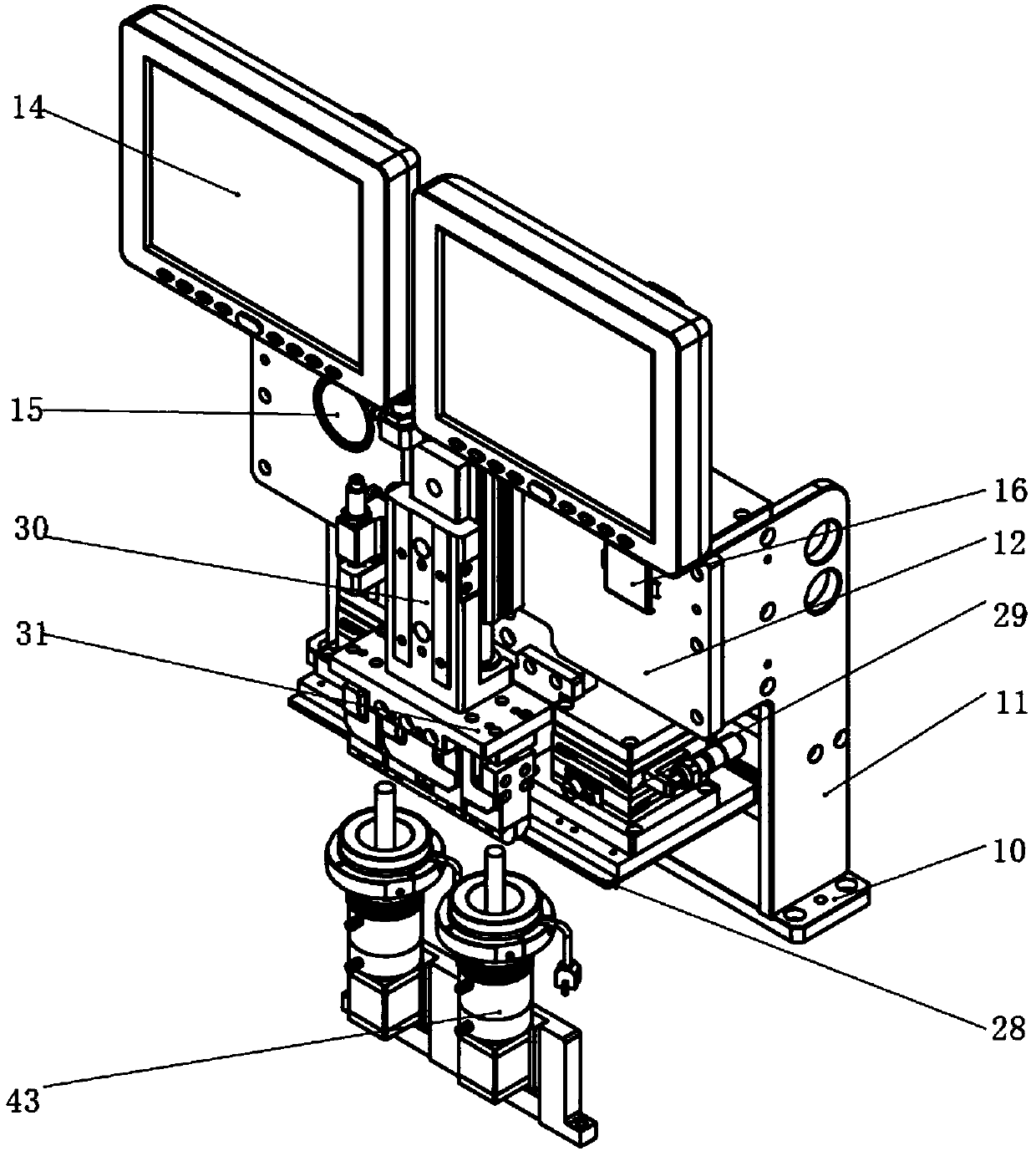

[0034]see figure 1 , which is a structural schematic diagram of a gear noise testing machine according to the present invention, including:

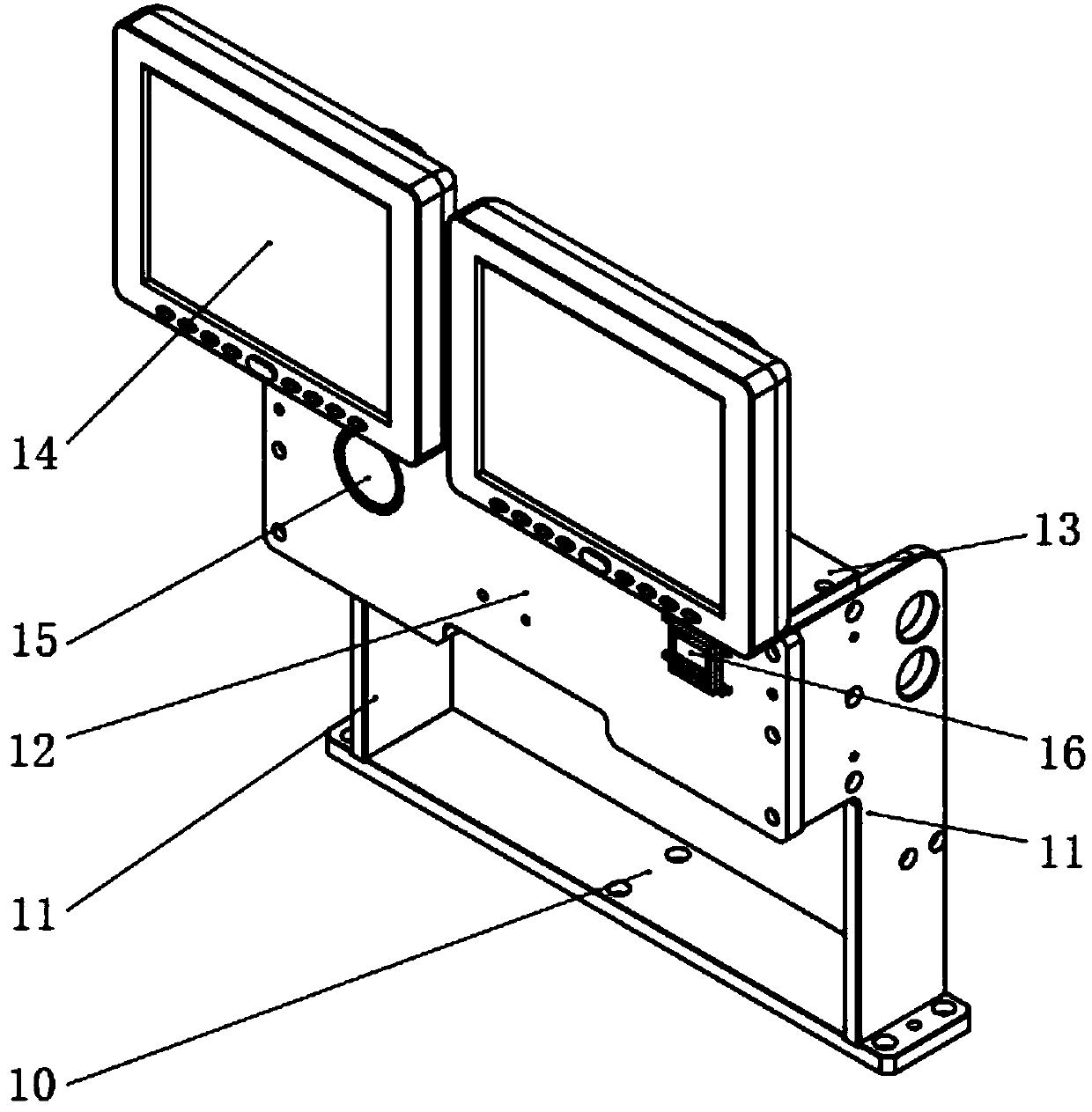

[0035] Mechanism outer frame unit: see figure 2 , comprising a mounting base plate 10, side plates 11 are vertically arranged on both sides of the mounting base plate 10, a front panel 12 is connected to the upper end of the two side plates 11, a display screen mounting plate 13 is connected to the top of the two side plates 11, and the display screen is installed Two display screens 14 are arranged symmetrically on the board 13, and the display screens 14 protrude outward;

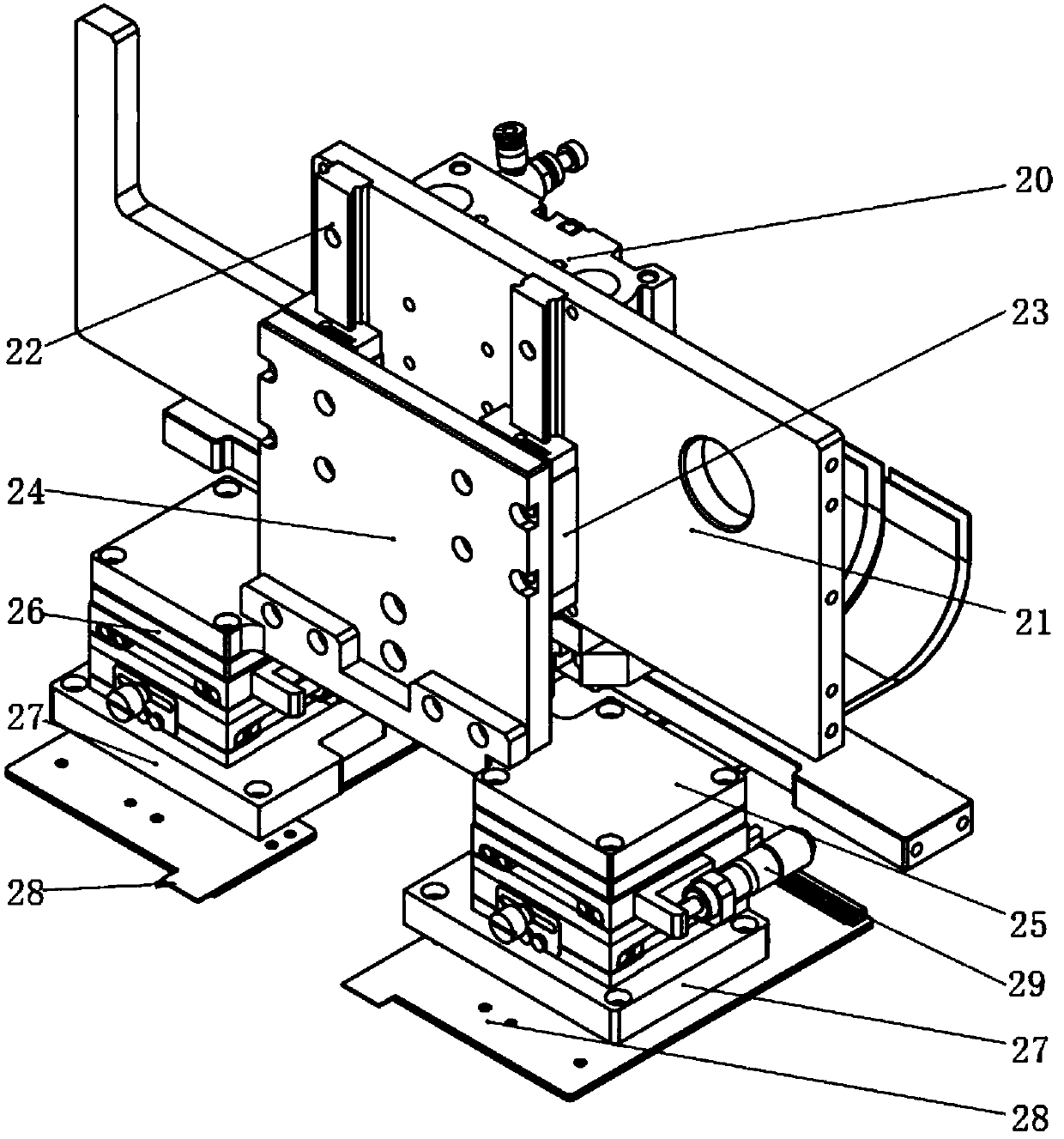

[0036] Test unit: see image 3 , including a cylinder 20, the surface of the cylinder 20 is fixed with a first mounting plate 21, two high-precision line rails 22 are installed on the upper part of the first mounting plate 21, and two high-precision sliders 23 are correspondingly arranged directly below the high-precision line rails 22, The surface of the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com