Integrated fabricated combined beam bridge construction method

A construction method and an assembled technology, which are applied in the construction field of integrally assembled composite girder bridges, can solve problems such as poor effectiveness, large-scale lifting equipment and road transportation conditions, and unreasonable stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

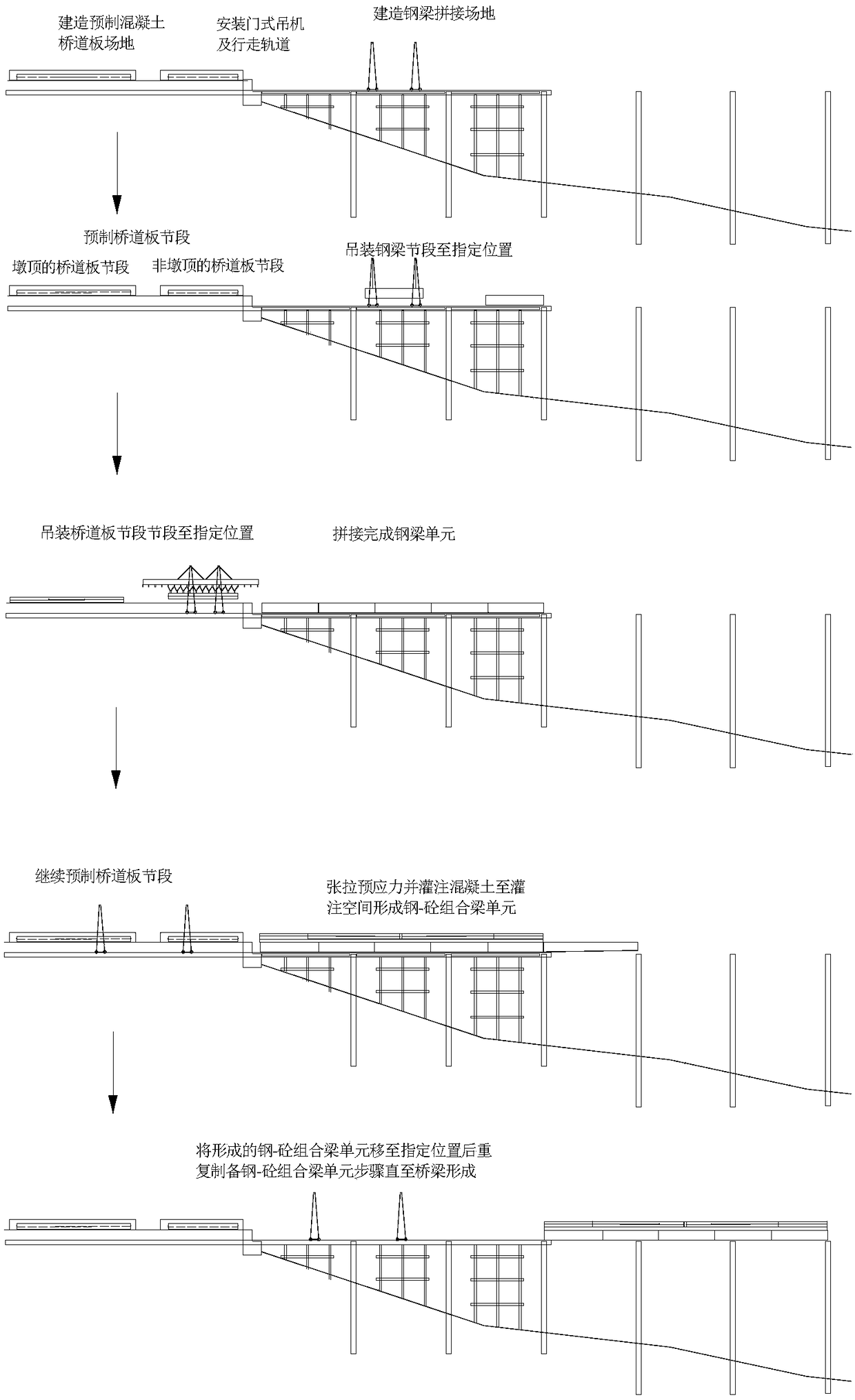

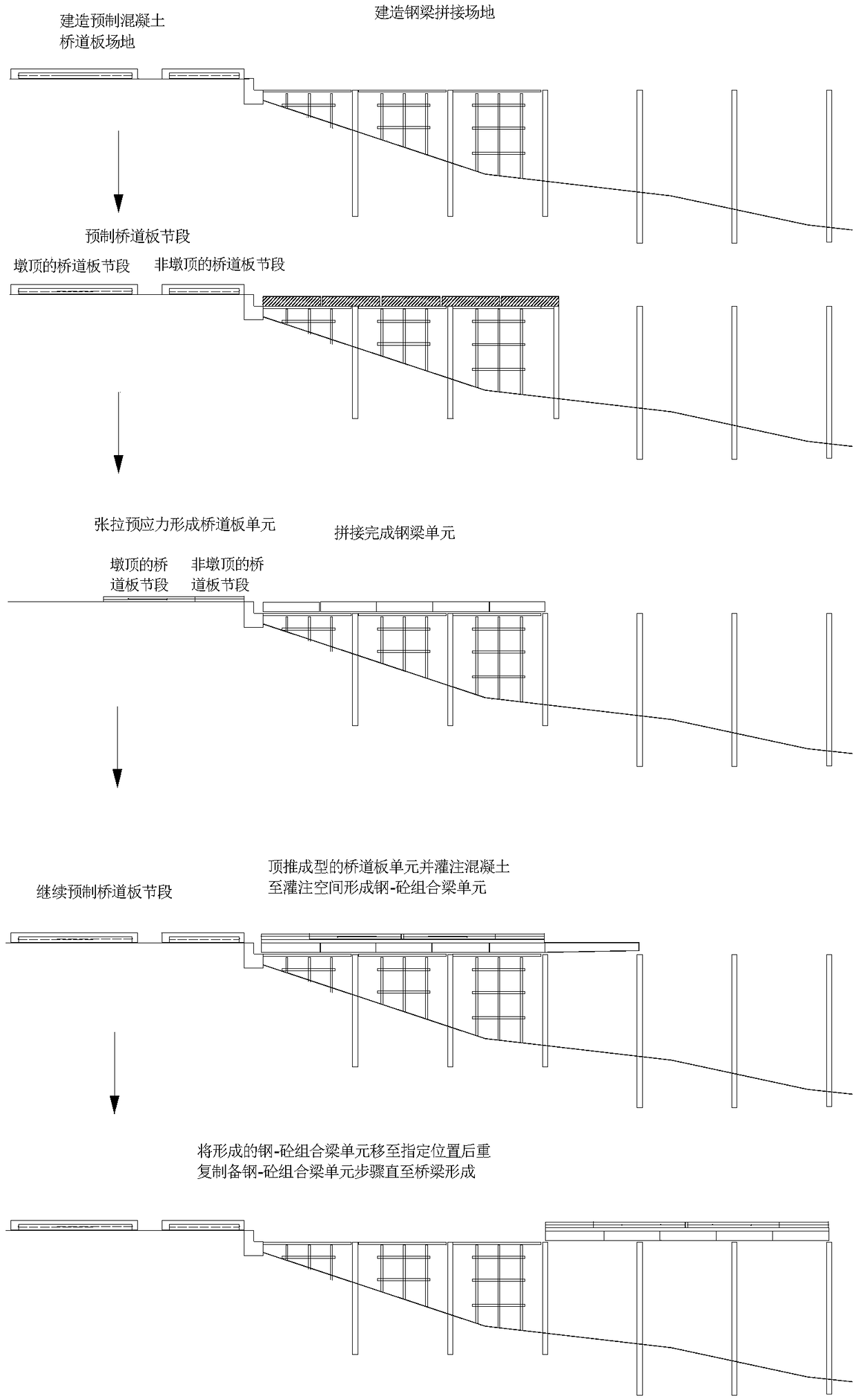

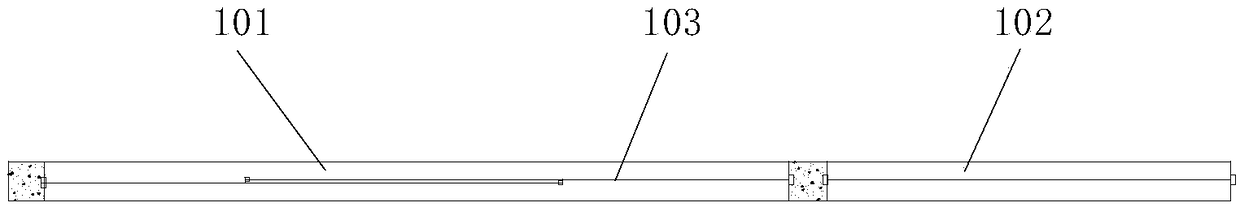

[0038] Such as figure 1 , figure 2 Shown: the present invention also discloses a steel-concrete composite beam bridge factory construction method used in the construction method of the integrally assembled composite beam bridge, comprising the following steps:

[0039] a. Build the prefabricated bridge slab site at a suitable position in front of the bridge head, and build the steel girder splicing site behind the prefabricated bridge slab site; the front of the bridge head refers to the extension direction of the bridge head, and the side toward the middle of the bridge is opposite to the rear; prefabricated bridge The road slab site and the steel girder splicing site are arranged side by side to form a prefabricated bridge head factory that can build the upper structure of the overall steel-concrete composite beam bridge, which is convenient for continuous construction and improves work efficiency. The construction of the site has different constructions according to differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com