Double-sided grinding/polishing machine with automatic speed-changing function, for optical glass screen

An automatic variable speed and optical glass technology, which is applied in the field of polishing machines, can solve problems such as the difficulty in processing optical glass screens, and achieve the effects of ensuring parallelism, small impact, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

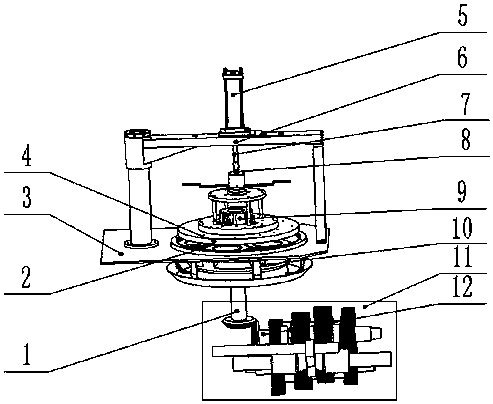

[0028]The automatic speed-variable double-sided grinding / polishing machine for optical glass screens comprises: a lifting support system (6), an upper grinding system (4), a lower grinding system (2), a box body and a bottom plate (3), an automatic Speed change system (11) is made up of five parts. It is characterized in that: there is an automatic transmission system (11) inside the box body and the bottom plate (3). The main motor is input to the automatic variable speed transmission system through gears. The worker selects different grinding speeds through the thickness of the glass screen, and through the fork mechanism and the synchronizer (19, 13) realizes different helical gear meshes and outputs different speeds to the outer transmission inner sleeve (35), and the outer transmission inner sleeve (35) is respectively connected to the upper The grinding disc drive sleeve (9) is connected to the lower grinding disc support seat (10). Ensure that the upper grinding sys...

Embodiment 2

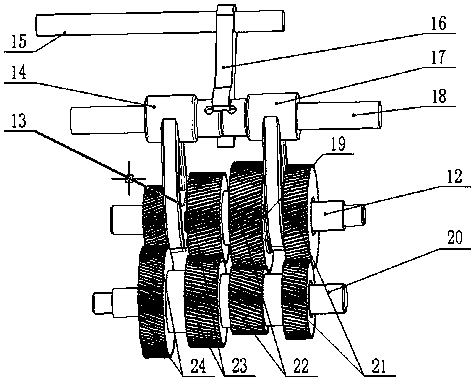

[0030] According to the automatic speed-variable double-sided grinding / polishing machine for optical glass screens described in Embodiment 1, the automatic speed-variable transmission system includes a fork mechanism and a speed-change mechanism. The shift fork mechanism includes: a swing arm shaft (15), a swing arm (16), a shift fork shaft (18) with interlock pin holes, a first shift fork (14), and a second shift fork (17). The speed change machine includes: input shaft (20), 1st gear acceleration helical gear (21), 2nd gear acceleration helical gear (22), 3rd gear same speed helical gear (23), 4th gear deceleration helical gear (24), 1 / 2 Gear synchronizer (19), 3 / 4 gear synchronizer (13), output shaft (12). The worker selects the grinding speed for glass screens of different thicknesses, and connects the first shift fork (14) or the second shift fork (17) through the swing arm (16). The first shift fork (14) is connected with the 1 / 2 gear synchronizer (19) through the L gro...

Embodiment 3

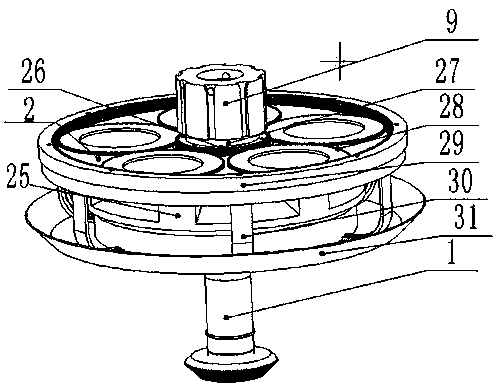

[0032] According to the double-sided grinding / polishing machine for automatic speed-variable optical glass screens described in Embodiment 1, the lower grinding system includes: an outer transmission inner sleeve (1), a pinion gear transmission connection cover (27), a pinion gear ( 26), upper grinding disc drive sleeve (9), lower grinding disc (2), planetary tooling gear (28), large gear (29), large ring gear support seat (30), lower grinding disc support seat (25), Recovery tank (31). The outer transmission inner sleeve (1) is connected with the variable speed transmission system. The outer transmission inner sleeve (1) transmits power to the pinion gear transmission connection cover (27) and the upper grinding disc drive sleeve (9). The pinion gear transmission connection cover (27) cooperates with the pinion gear (26) to drive the pinion gear (26) to rotate, so that the meshed planetary tooling gear (28) winds around the pinion gear (26) and the bull gear (29) Revolution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com