Low-after-shrinkage polypropylene composite material for automobile bumper and preparation method thereof

A composite material, polypropylene technology, applied in the field of low post-shrinkage polypropylene composite material and its preparation, can solve the problems of glass fiber floating fiber, material toughness decrease, modulus decrease, etc., achieve excellent comprehensive performance, reduce shrinkage rate, The effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

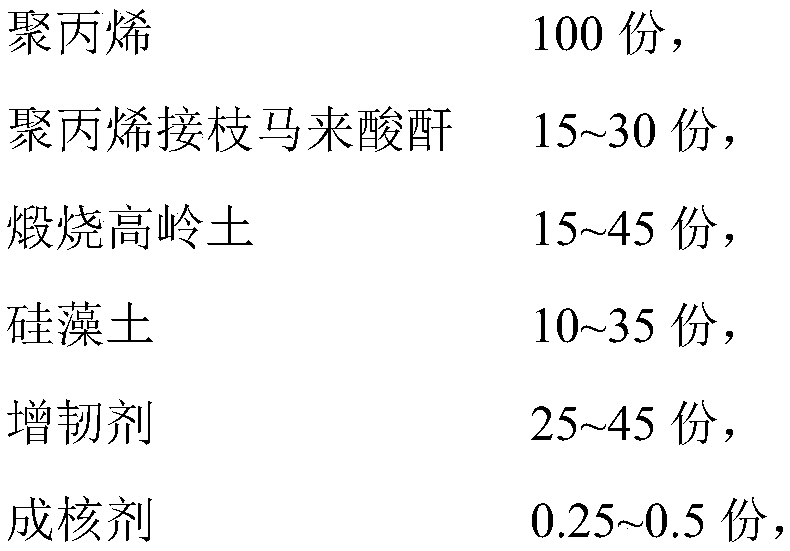

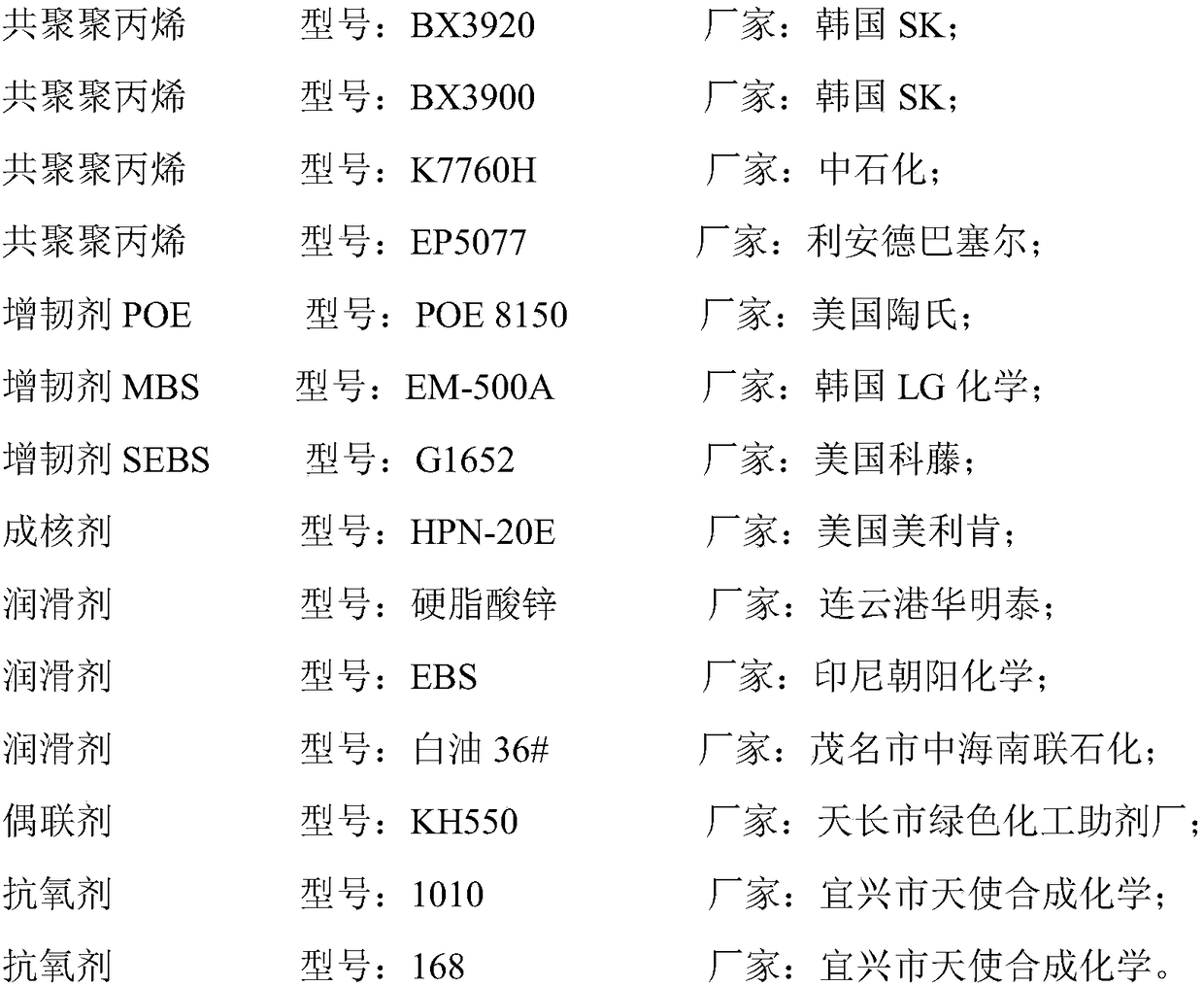

Method used

Image

Examples

Embodiment 1

[0037] Step 1: Weigh 15 parts of calcined kaolin in high-speed mixer A, then add 0.08 parts of lubricant zinc stearate and 0.12 parts of lubricant ethylene bis stearic acid amide and mix for 20 minutes, then take out the mixed modified 2 / 5 of the total weight of calcined kaolin is reserved; then take 10 parts of 3000 mesh glass fiber powder in high-speed mixer A and mix with 3 / 5 of the total weight of modified calcined kaolin for 20 minutes; the speed of high mixer A is 200 rpm, temperature 50°C.

[0038] Step 2: Weigh 60 parts of polypropylene BX3900, 40 parts of polypropylene EP5077, 15 parts of polypropylene grafted maleic anhydride, 15 parts of toughening agent POE 8150, 7 parts of toughening agent EM-500A, 3 parts of toughening agent Put SEBS G1652 in high-speed mixer B, then add 0.25 parts of nucleating agent HPN-20E, 0.2 parts of coupling agent KH550 and mix for 20 minutes. The speed of the high mixer B is 200 rpm, and the temperature is 50°C.

[0039] Step 3: Add the...

Embodiment 2

[0042] Step 1: Weigh 45 parts of calcined kaolin in high-speed mixer A, then add 0.21 parts of lubricant zinc stearate and 0.19 parts of lubricant ethylene bis stearic acid amide and mix for 30 minutes, then take out the mixed modified 2 / 5 of the total weight of the calcined kaolin was used for later use; then 35 parts of 5000 mesh glass fiber powder were weighed and mixed with 3 / 5 of the total weight of the modified calcined kaolin in the high-speed mixer A for 30 minutes. The rotating speed of high mixer A is 300 rpm, and the temperature is 70°C.

[0043] Step 2: Weigh 58 parts of polypropylene BX3920, 42 parts of polypropylene EP5077, 30 parts of polypropylene grafted maleic anhydride, 30 parts of toughening agent POE 8150, 10 parts of toughening agent EM-500A, 5 parts of toughening agent Put SEBS G1652 in high-speed mixer B, then add 0.5 parts of nucleating agent HPN-20E, 0.3 parts of coupling agent KH550 and mix for 30 minutes. The speed of the high mixer B is 300 rpm, a...

Embodiment 3

[0047] Step 1: Weigh 21 parts of calcined kaolin in high-speed mixer A, then add 0.09 parts of lubricant zinc stearate and 0.17 parts of lubricant ethylene bis stearic acid amide and mix for 23 minutes, then take out the mixed modified 2 / 5 of the total weight of the calcined kaolin is used for later use; then, 12 parts of 5000-mesh glass fiber powder are weighed and mixed with 3 / 5 of the total weight of the modified calcined kaolin in the high-speed mixer A for 27 minutes. The rotating speed of high mixer A is 234 rpm, and the temperature is 57°C.

[0048] Step 2: Weigh 43 parts of polypropylene K7760H, 57 parts of polypropylene EP5077, 19 parts of polypropylene grafted maleic anhydride, 19 parts of toughening agent POE 8150, 7 parts of toughening agent EM-500A, 5 parts of toughening agent Put SEBS G1652 in high-speed mixer B, then add 0.29 parts of nucleating agent HPN-20E, 0.24 parts of coupling agent KH550 and mix for 24 minutes. The speed of high mixer B is 209 rpm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com