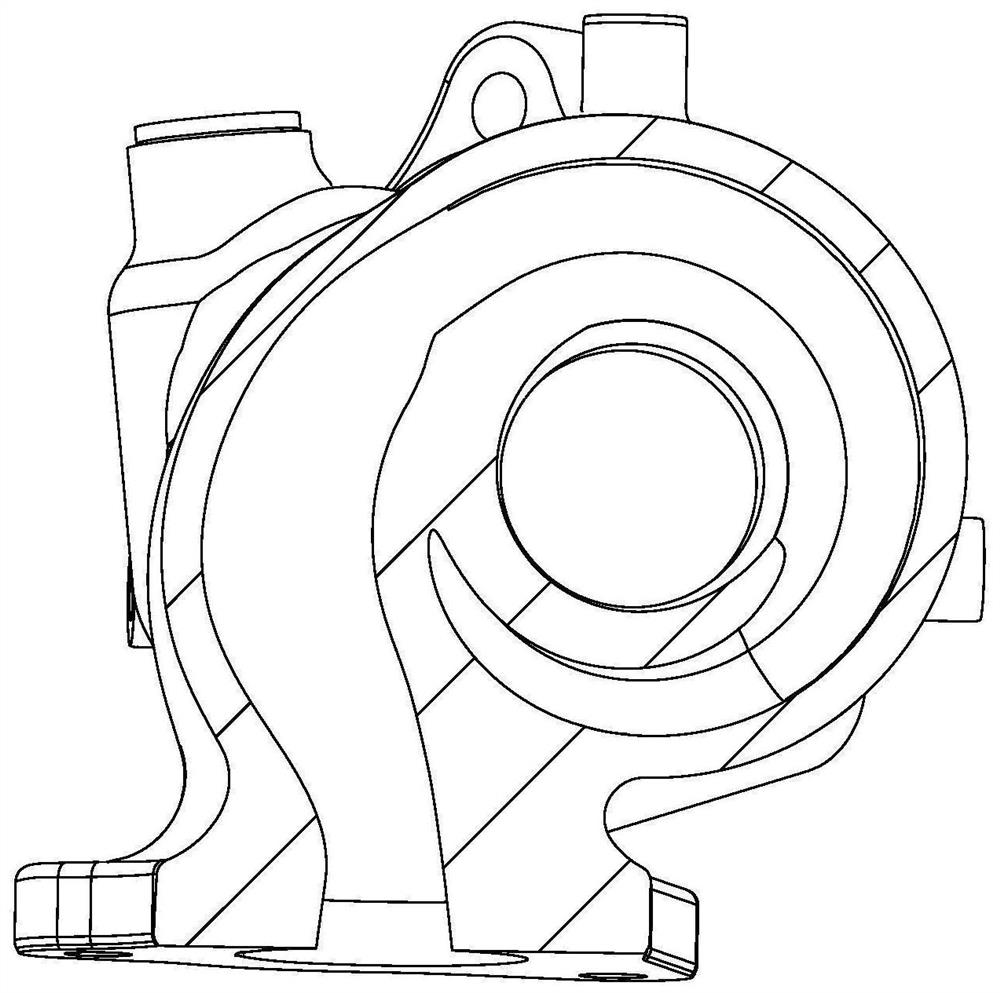

Turbine casing runner detection system and method

A technology for detection systems and turbine shells, applied to measuring devices, instruments, etc., can solve the problems of blind spots, high cost, and large labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

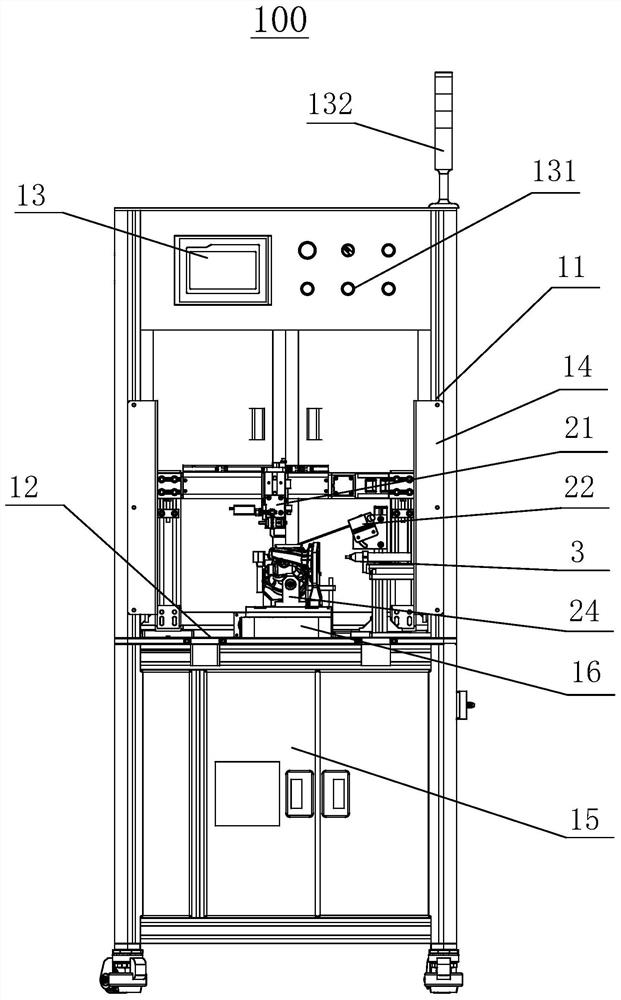

[0038] Please refer to figure 1 , the present embodiment provides a turbine shell runner detection system 100, including a workbench, a functional mechanism, a marking mechanism 3 and a control system.

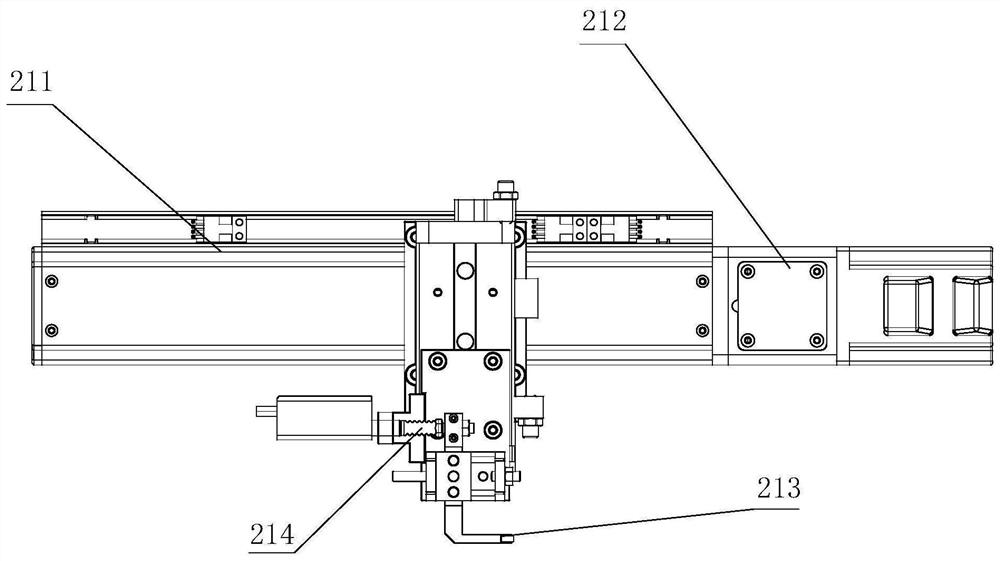

[0039] In this embodiment, the workbench provides a platform for supporting the workpiece, and the functional mechanism is installed on the workbench. The functional mechanism includes a mechanical roller detection device 21, a laser displacement detection device 22, an elastic detection device 23 and a rotary positioning device 24. The positioning device 24 can realize the positioning and rotating operation of the workpiece. The mechanical roller detection device 21, the laser displacement detection device 22 and the elastic detection device 23 detect the workpiece step by step, improve the mechanization of workpiece detection, improve the detection accuracy and detection efficiency; through the marking mechanism 3. Realize the distinction between qualified and unqualified wo...

no. 2 example

[0062] This embodiment provides a method for detecting a flow path of a turbine casing, using the detection system 100 for a flow path of a turbine casing provided in the first embodiment, including the following steps:

[0063] Step S1: Place the workpiece on the workbench, clamp and position the workpiece through the rotary positioning device 24, rotate the workpiece for one circle, and at the same time as the workpiece rotates, the laser displacement detection device 22 uses the laser beam to feed back the distance parameter H1 from the inner surface of the workpiece to the receiver to the external controller, and compared with the first preset value Y1, if H1 does not fall within the range of Y1, the workpiece is unqualified;

[0064] Step S2: Rotate the workpiece to the initial position, the mechanical roller detection device 21 moves to the designated position and contacts the surface of the workpiece, rotates the workpiece to the 270° position, the roller probe of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com