Simulated nuclear magnetic resonance analysis system and applications thereof

A nuclear magnetic resonance and analysis system technology, applied in the direction of using nuclear magnetic resonance for analysis, etc., to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 A kind of simulation nuclear magnetic resonance analysis system

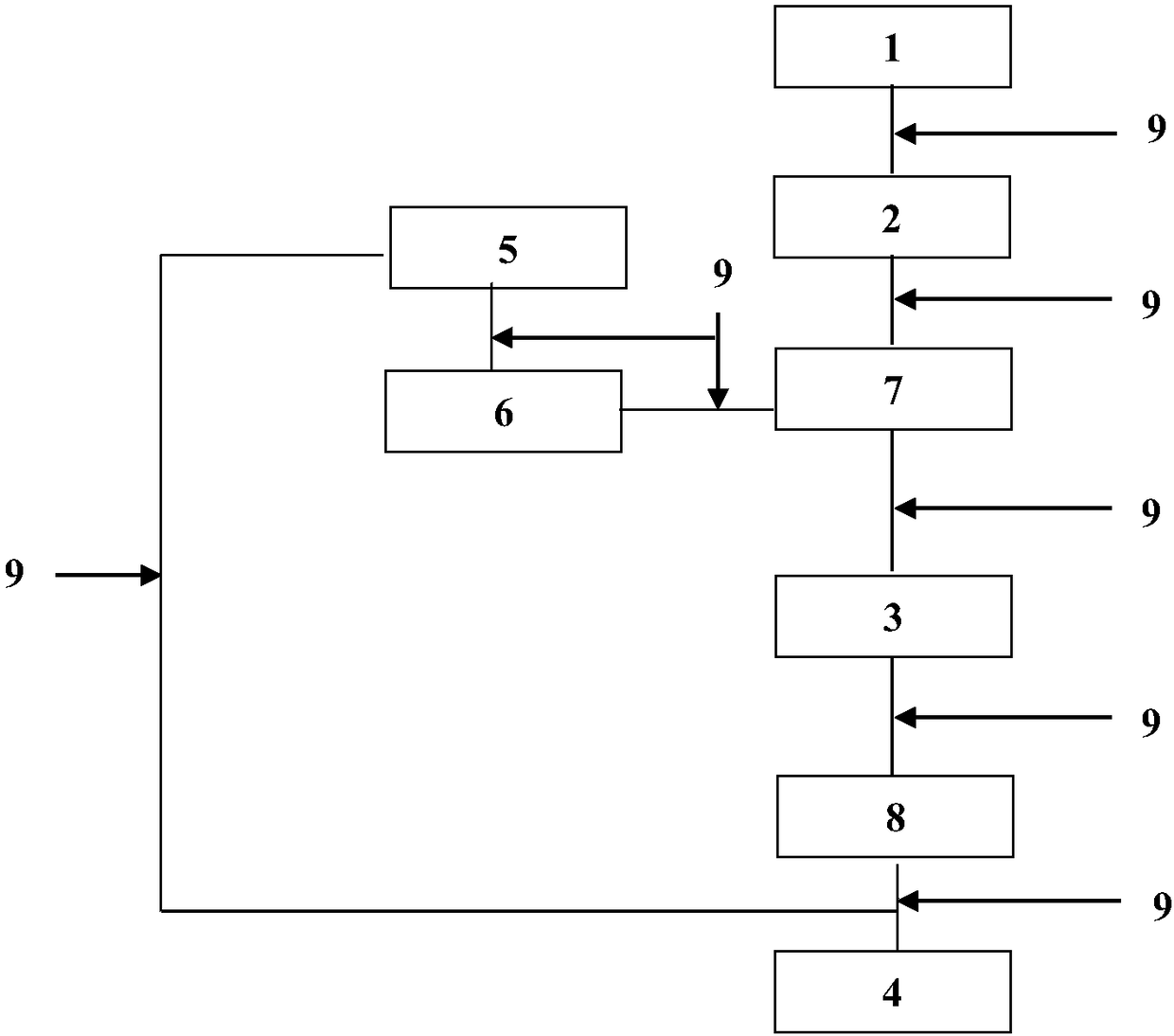

[0052] The structural representation of the simulation nuclear magnetic resonance analysis system, see figure 1 , including nitrogen storage device with valve 1, sample tank with heating device 2, Aspect AI-60 online nuclear magnetic resonance analyzer 3, waste oil tank 4, cleaning oil tank with heating device 5, circulation pump 6, three Through valve 7 and 8, and pipeline 9; Wherein, nitrogen storage device 1, sample tank 2, three-way valve 7, on-line nuclear magnetic resonance analyzer 3, three-way valve 8 and waste oil tank 4 are sequentially connected through pipeline 9, cleaning oil Tank 5, circulation pump 6, three-way valve 7, on-line nuclear magnetic resonance analyzer 3 and three-way valve 8 form a closed circuit through pipeline 9; It is connected with the circulation pump 6, and the sample outlet of the online nuclear magnetic analyzer 3 is respectively connected with the waste o...

Embodiment 2

[0055] Example 2 Application of Simulation NMR Analysis System in Offline Analysis of Crude Oil Samples

[0056] Utilize the simulated nuclear magnetic resonance analysis system of embodiment 1, analyze the crude oil sample offline, the specific operation steps are:

[0057] I. Shimming

[0058] Use aviation kerosene as the cleaning oil, add 5L of cleaning oil to the cleaning oil tank 5, heat to 70±5°C, switch the three-way valves 7 and 8, and make the cleaning oil tank 5, circulation pump 6 and Aspect AI-60 online NMR The resonator 3 constitutes a closed circuit through the pipeline 9, and the circulation pump is turned on, and the cleaning oil circulates between the cleaning oil tank 5 and the nuclear magnetic resonance instrument 3, and the reference test is carried out to find the nuclear magnetic signal. Because the conditions are not met, shimming is carried out Operation, until the magnetic field of the nuclear magnetic resonance analyzer is stable;

[0059] II. Deter...

Embodiment 3

[0071] Example 3 Application of Simulated NMR Analysis System in Offline Analysis of Hydrogenated Diesel Raw Material Samples

[0072] Using the simulated nuclear magnetic resonance analysis system of Example 1, the hydrogenated diesel raw material sample was analyzed offline according to the same steps as in Example 2, except that the test sample was a hydrogenated diesel raw material.

[0073] In addition, the laboratory uses a varioEL-cube hydrocarbon analyzer to measure the carbon and hydrogen contents of the same batch of samples, and the analysis standard is SH / T0656-1998.

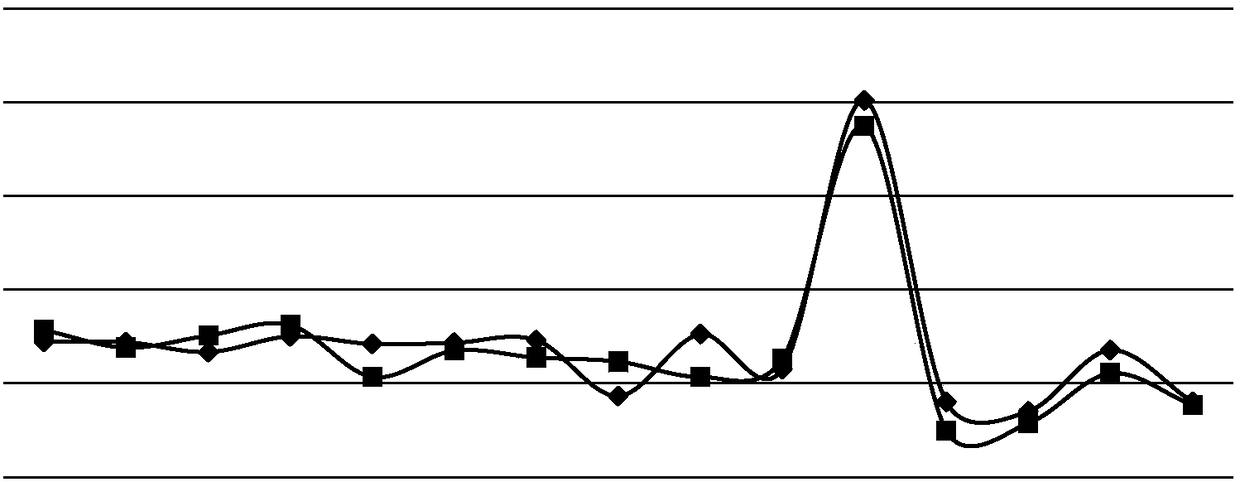

[0074] The results of the two methods are shown in Table 4.

[0075] Table 4 The carbon content and hydrogen content of hydrogenated diesel feedstock determined by two analytical methods

[0076]

[0077]

[0078] a : Carbon content standard deviation value=2.4; b : hydrogen content standard deviation value = 0.78.

[0079] The results in Table 4 show that the carbon content and hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com