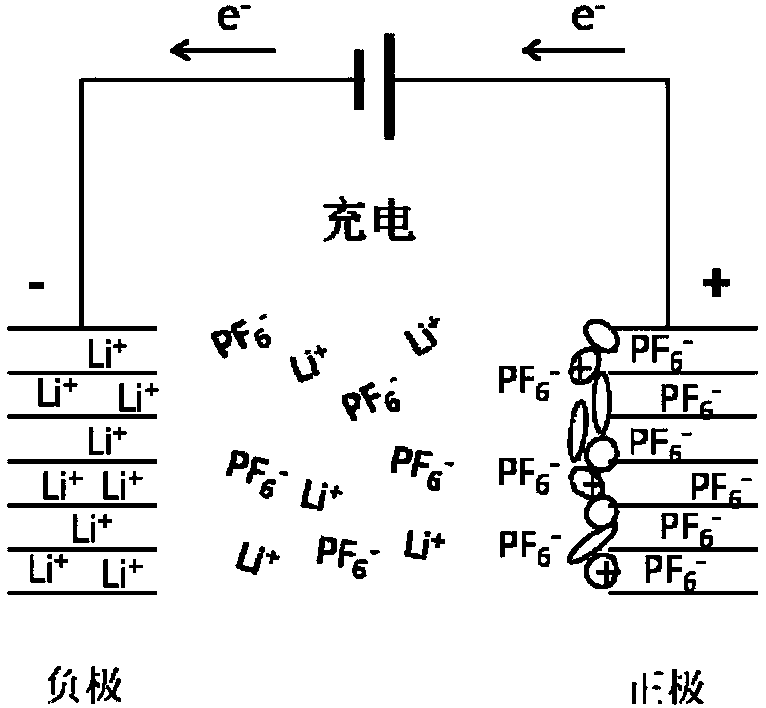

Dual-ion capacitor battery

A capacitor battery and dual-ion technology, applied in double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of poor cycle stability, limited charge-discharge specific capacity, low coulomb efficiency, etc., and achieve high energy density, stable Embedding, resolving coulomb inefficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step: mix natural graphite, graphene, and PVDF binder (PVDF is dissolved in NMP, the concentration is 1%wt) according to the ratio of 7:2:1, and then coat it on the aluminum grid and dry it as the positive electrode piece.

[0038] Step 2: Mix mesocarbon microspheres, conductive carbon black, PVDF binder (PVDF dissolved in NMP, concentration 1%wt) according to the ratio of 8:1:1, and then coat it on the aluminum foil Dry as a negative electrode sheet.

[0039] Step 3: The diaphragm adopts glass microfiber diaphragm, and the electrolyte adopts 4mol / L LiPF 6 EMC (ethyl methyl carbonate) solution.

[0040] Step 4: In an environment with controlled water and oxygen content, superimpose the above-mentioned electrode sheets and separators in the order of positive electrode sheet, separator, and negative electrode sheet in the CR2032 battery case, inject an appropriate amount of electrolyte, and seal the battery case to make a button battery.

[0041] Step 5: Carr...

Embodiment 2

[0043] Step 1: Mix mesophase carbon microspheres, activated carbon, and PVDF binder (PVDF is dissolved in NMP at a concentration of 1%wt) in a ratio of 6:3:1, and then coat and dry on carbon cloth dry as the positive electrode.

[0044] The second step: mix natural graphite, conductive carbon black, and PVDF binder (PVDF is dissolved in NMP, the concentration is 1%wt) according to the ratio of 8:1:1, and then coat it on aluminum foil and dry it as Negative plate.

[0045] The third step: the diaphragm adopts PP polymer diaphragm, and the electrolyte adopts 2mol / L LiTFSI ethyl methyl carbonate (EMC) solution.

[0046] Step 4: In an environment with controlled water and oxygen content, superimpose the above-mentioned electrode sheets and separators in the order of positive electrode sheet, separator, and negative electrode sheet in the aluminum-plastic film, inject an appropriate amount of electrolyte, and seal the aluminum-plastic film to make a small soft pack battery .

[...

Embodiment 3

[0049] The first step: mix natural graphite, activated carbon, PTFE binder (PTFE dissolved in deionized water, the concentration is 40%wt) according to the ratio of 4:4:2, and then coat it on the nickel foam and dry it as Positive sheet.

[0050] The second step: directly use metal aluminum foil as the negative electrode.

[0051] Step 3: The diaphragm is made of glass microfiber, and the electrolyte is made of 6mol / L LiPF 6 solution of ethyl methyl carbonate (EMC).

[0052] The fourth step: same as embodiment 1

[0053] Step 5: Carry out the electrochemical performance test of the above-mentioned button battery, wherein the charging and discharging test voltage range is 3V-5V, and the specific test results are shown in Table 1.

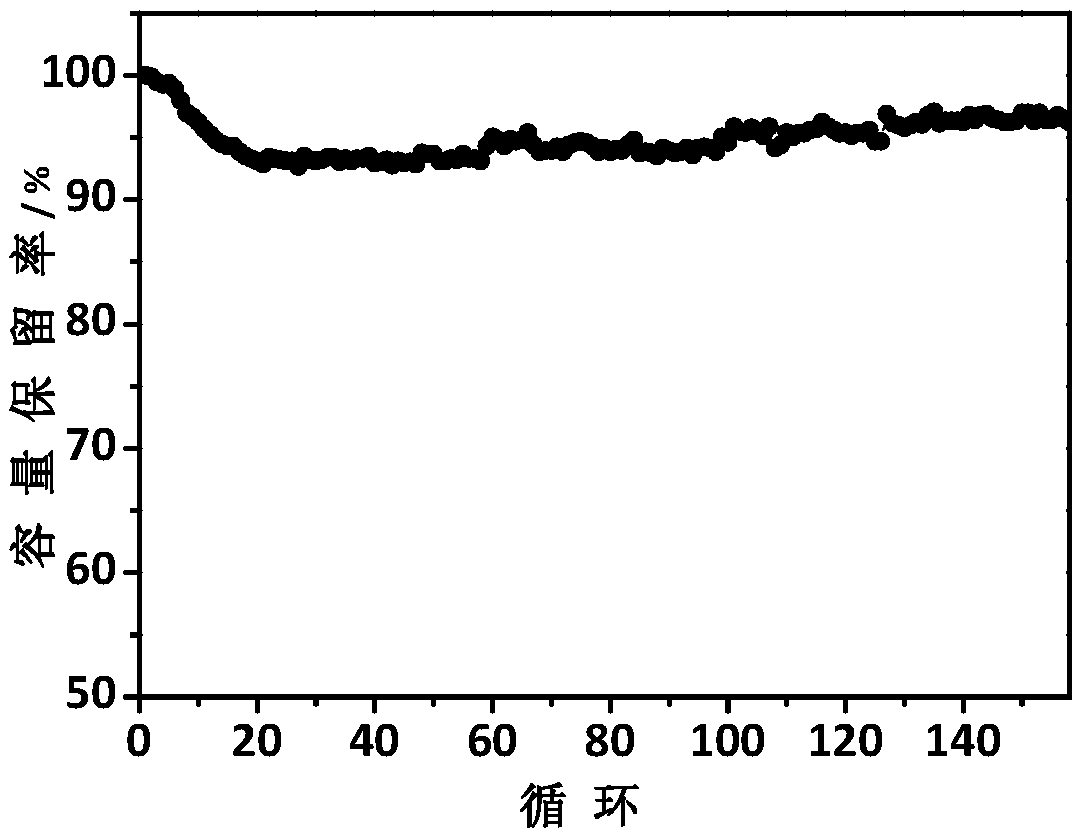

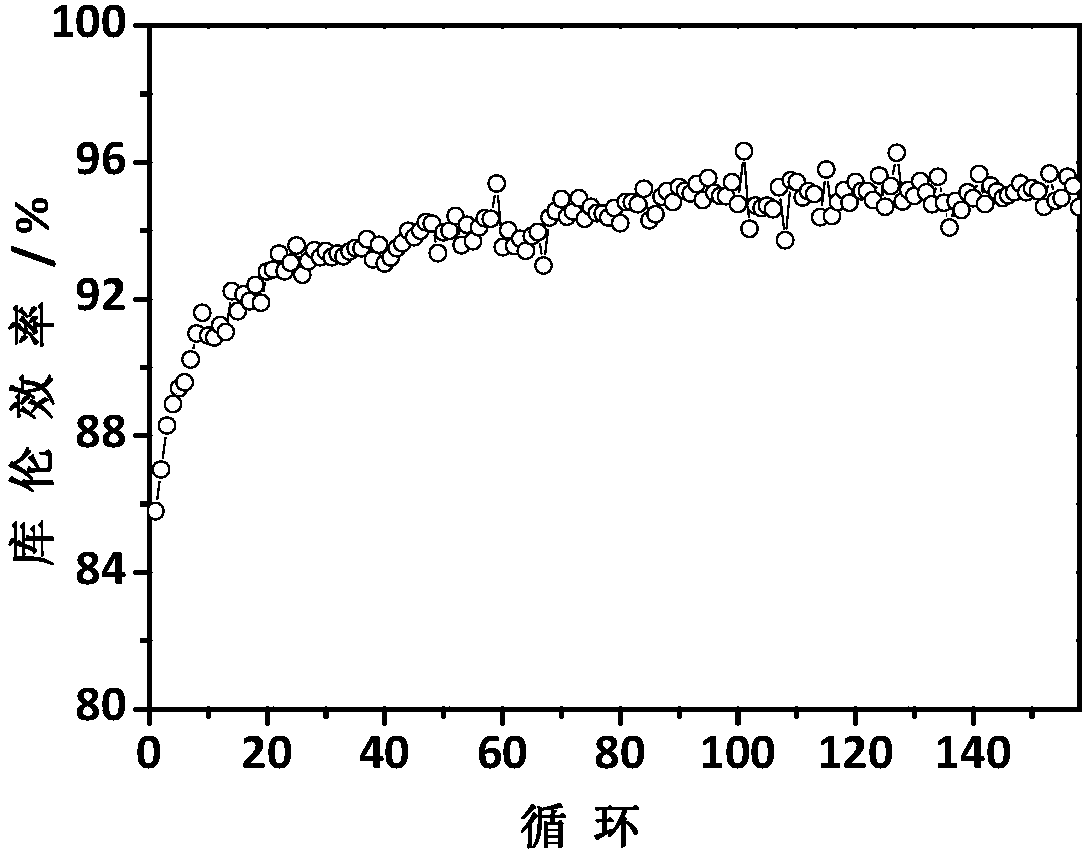

[0054] Embodiment 3 test result such as figure 2 and image 3 As shown, among them, constant current charging and discharging is adopted, the charging and discharging voltage range is 3-5V, and the charging and discharging rate is 0.5C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com