Solar cell and method for manufacturing the same

A technology for solar cells and electrodes, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as poor passivation properties, complex doping processes, and deterioration of semiconductor substrate interface properties, to enhance productivity, improve Efficiency and reliability, effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

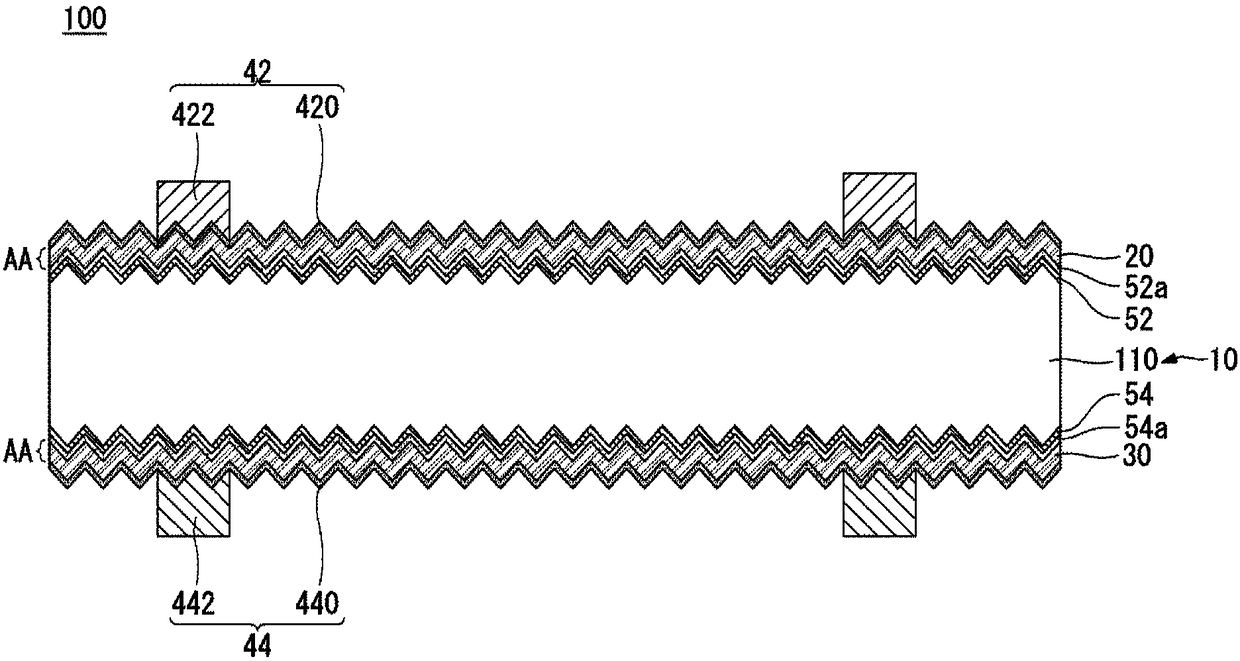

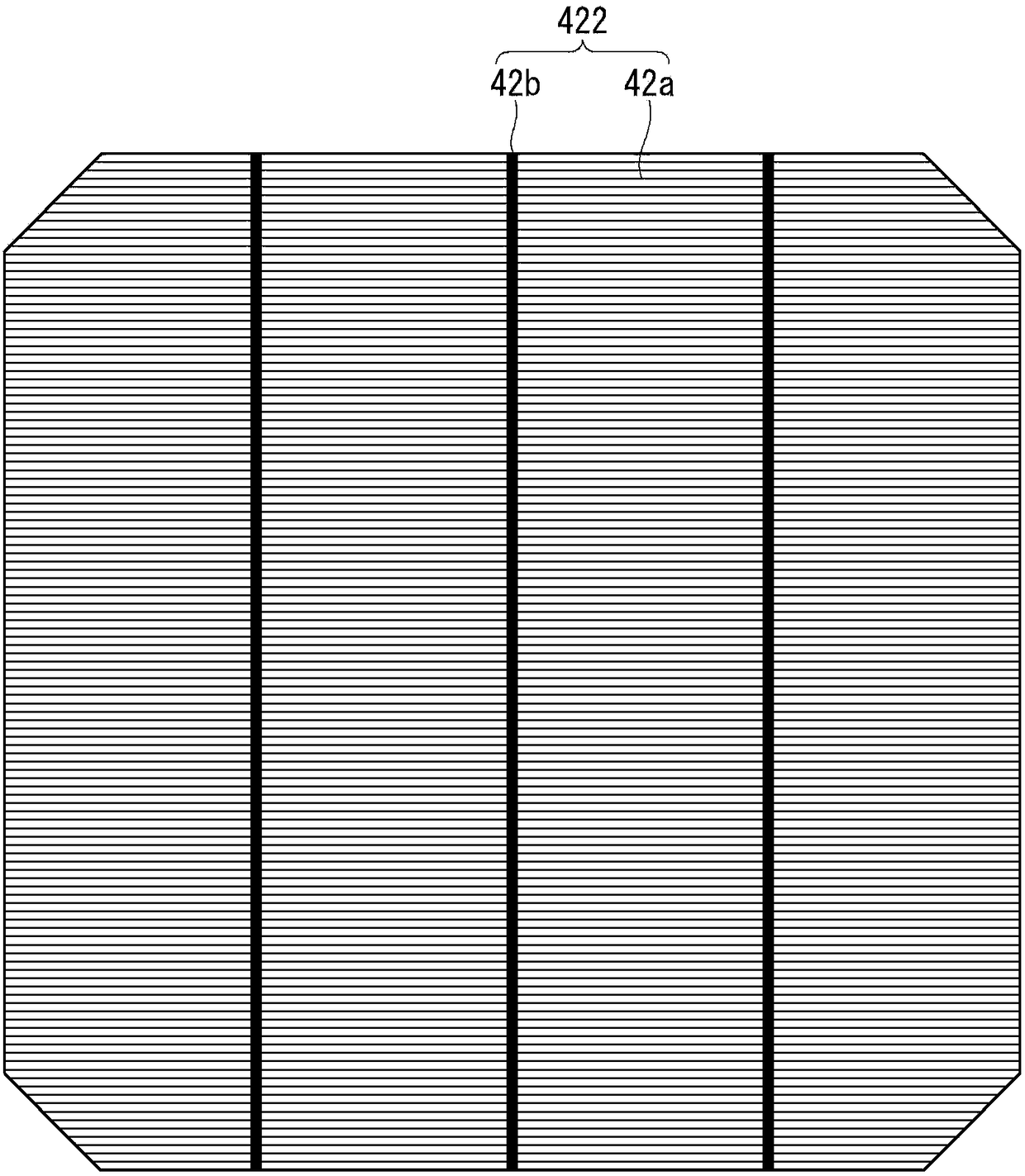

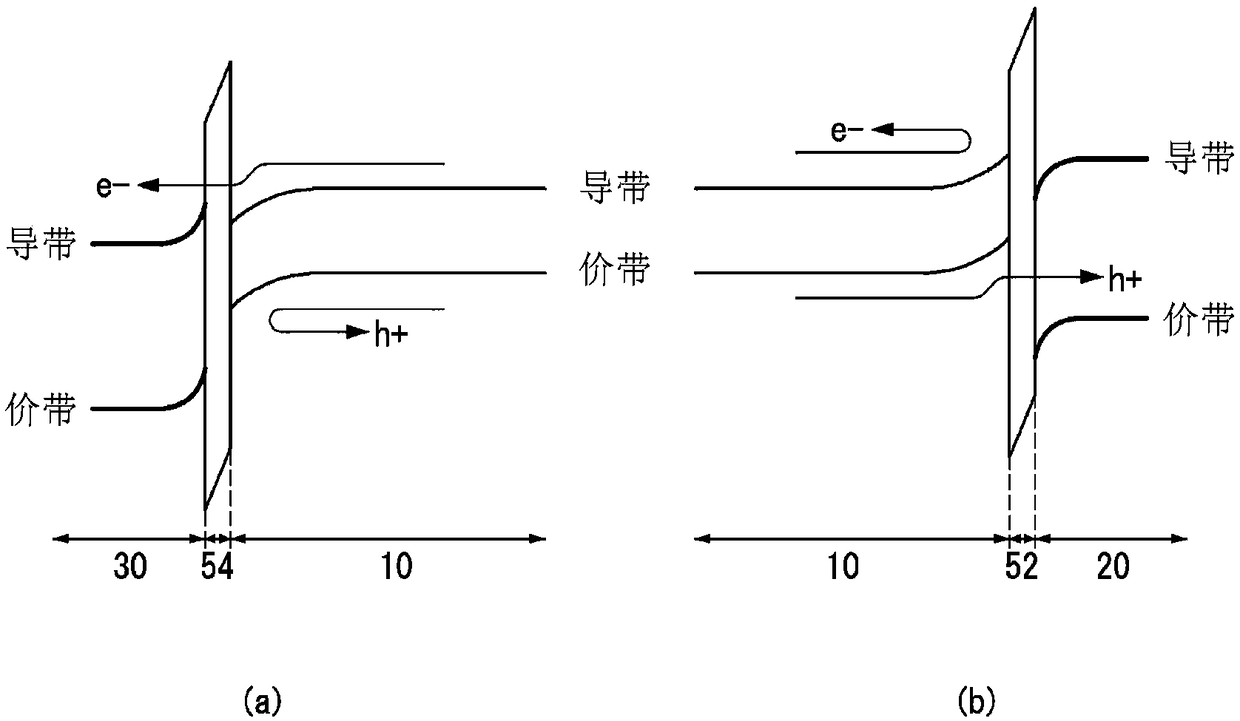

[0140] A first tunneling layer and a second tunneling layer formed of amorphous silicon are formed on a front surface and a rear surface of an n-type single crystal silicon substrate. A first intermediate layer formed of a silicon oxide layer having hydroxyl groups is formed on the first tunneling layer, and a second intermediate layer formed of a silicon oxide layer having hydroxyl groups is formed on the second tunneling layer. A first conductive region formed of a molybdenum oxide layer and a second conductive region formed of a titanium oxide layer are formed. The first intermediate layer and the second intermediate layer were formed through an atomic layer deposition process and had a thickness of 0.5 mm. The first conductive region is formed by an atomic layer deposition process at a process temperature of 200° C. and has a thickness of 10 nm, and the second conductive region is formed by an atomic layer deposition process at a process temperature of 200° C. and has a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com