Production method for solar cell panel

A technology for solar panels and production methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the quality of solar panels cannot be optimal, and achieve the effects of ensuring photoelectric conversion efficiency, reasonable design, and optimized wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The present embodiment provides a kind of production method of solar panel, comprises the following steps:

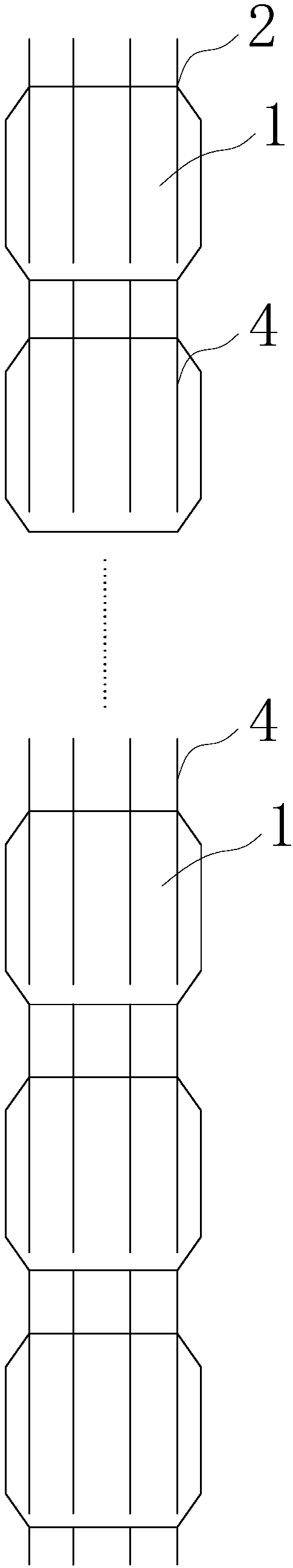

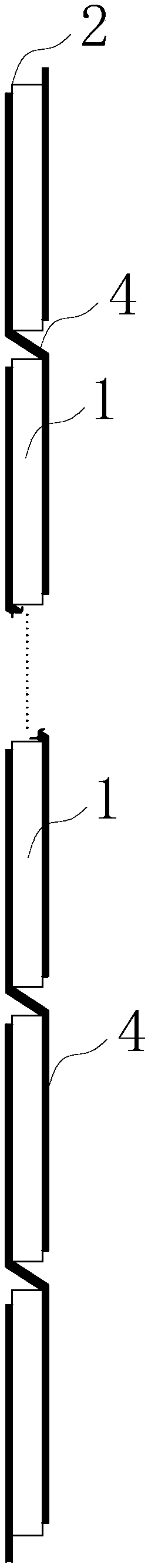

[0072] (1) if Figure 2 ~ Figure 3 As shown, a single battery piece 1 is connected in series into a battery string 2 by a stringer, and the positive and negative electrodes of adjacent battery pieces 1 are welded by interconnecting bars 4 .

[0073] Using a stringer to weld a single battery piece 1 into a battery string 2 is more efficient than manual welding, and the yield is higher; and it is more accurate, ensuring that the battery piece 1 does not shift back and forth; after the string welding is completed, the battery string 2. Check to see if there is any false welding or whether the cell 1 is damaged, so as to eliminate unqualified products.

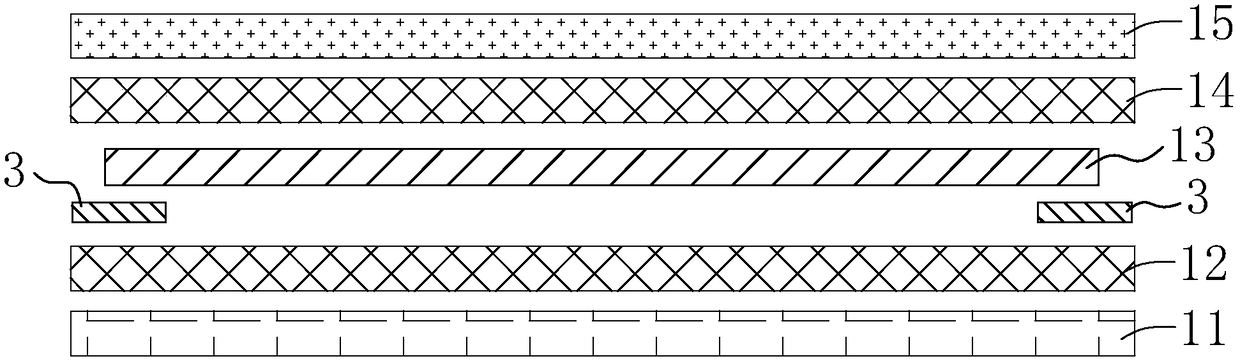

[0074] (2) if figure 1 As shown, the tempered glass plate 11, the first packaging adhesive layer 12, the battery pack 13, the second packaging adhesive layer 14 and the back plate 15 are sequentially stacked to for...

Embodiment 2

[0093] see Figure 7 , the difference between this embodiment and embodiment 1 is:

[0094] The heat shield 3 is transparent, the horizontal calibration line 31, the bus bar placement line 32, and the interconnection bar reference line 33 are all dark lines; the workbench 6 is placed on the ground, and the table top of the workbench 6 61 is transparent glass, the side wall 62 of workbench 6 is a solid baffle, and workbench 6 is provided with illuminating lamp 63 inside.

[0095] Because the calibration and welding of the interconnection bar 4 and the bus bar 5 need sufficient brightness, but generally the workshop for producing solar panels is very empty, the light distance is relatively long, and the light intensity is not enough; if a separate light source is set around the workbench 6, it will It takes up extra space and affects the operation of the staff.

[0096] Therefore, the light source is arranged in the inside of the workbench 6, which will not affect the operatio...

Embodiment 3

[0098] The difference between this embodiment and embodiment 2 is:

[0099] see Figure 8 , the manipulator 10 is provided with a row of Bernoulli suction cups 7 for absorbing the battery slice 1 and carrying the battery string 2 .

[0100] see Figure 9 ~ Figure 10 , the Bernoulli suction cup 7 includes a suction cup body 71, a first suction cup core 72 fixed in the suction cup body 71, a second suction cup core 73 fixed in the first suction cup core 72, the underside of the first suction cup core 72 is in contact with An air outlet passage 74 is formed between the lower sides of the second suction cup core 73, and an air inlet passage 75 communicating with the top of the second suction cup core 73 is provided in the second suction cup core 73, and the inner wall of the second suction cup core 73 is provided with The air outlet hole 76 that communicates with the air inlet passage 75 and the air outlet passage 74; There is a connecting frame 78 for installing the suction cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com