Preparation method and application of complete feed for feeding goats at growth period

A full-price feed, goat technology, applied in the application, animal feed, animal feed and other directions, can solve the problem of not ideal, and achieve the effect of reducing input, increasing feed intake, and increasing body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

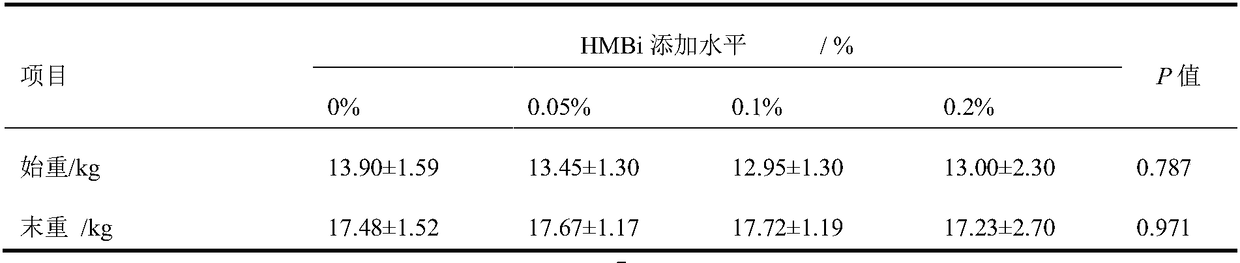

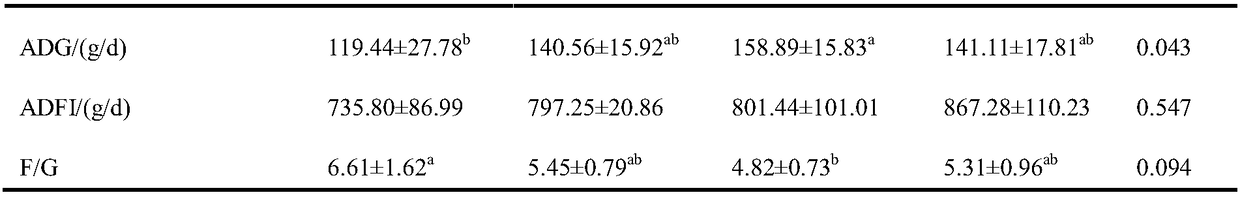

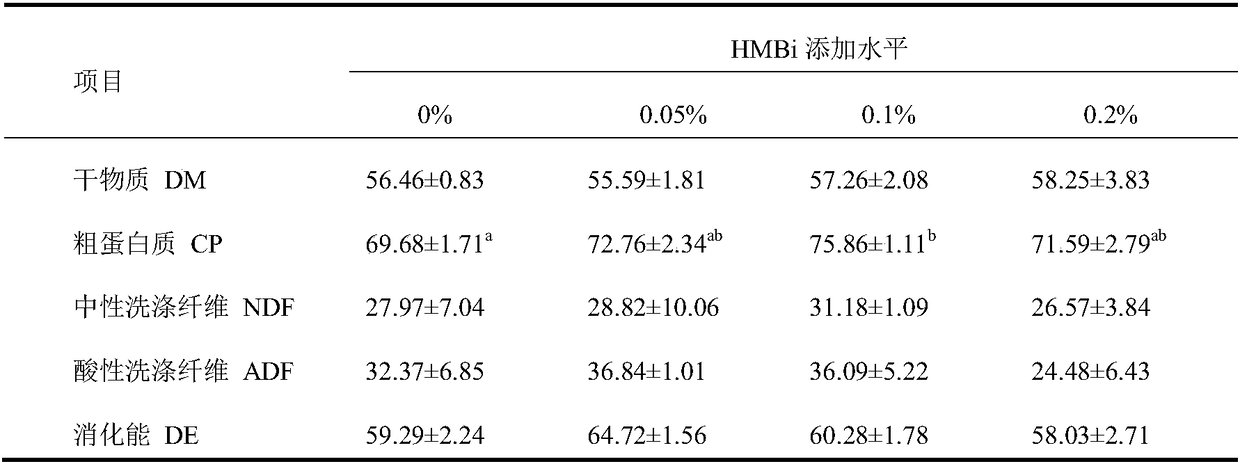

Examples

Embodiment 1

[0015] Raw material formula: its various components and their weight parts are: 31 parts of rice straw, 19 parts of alfalfa hay, 36 parts of corn, 3 parts of oil bran, 9.5 parts of soybean meal, 0.4 part of calcium carbonate, 0.4 part of table salt, calcium hydrogen phosphate 0.2 part, 0.1 part of methionine hydroxy analog isopropyl ester HMBi, 0.4 part of premix.

[0016] Feed preparation method:

[0017] Step S1: Prepare the HMBi-containing premix, and mix the components in a balanced manner;

[0018] Step S2: After accurate weighing, add each component into the feed mixer one by one, mix evenly, granulate, and control the water content at about 15%.

Embodiment 2

[0020] Ingredients: 30 parts of rice straw, 15 parts of alfalfa hay, 35 parts of corn, 3 parts of oil bran, 9 parts of soybean meal, 0.4 part of calcium carbonate, 0.4 part of table salt, and 0.4 part of calcium hydrogen phosphate 0.2 part, 0.1 part of methionine hydroxy analog isopropyl ester HMBi, 0.4 part of premix.

[0021] Feed preparation method:

[0022] Step S1: Prepare the HMBi-containing premix, and mix the components in a balanced manner;

[0023] Step S2: After accurate weighing, add each component into the feed mixer one by one, mix evenly, granulate, and control the water content at about 15%.

Embodiment 3

[0025] Raw material formula: its various components and their weight parts are: 35 parts of rice straw, 20 parts of alfalfa hay, 40 parts of corn, 4 parts of oil bran, 10 parts of soybean meal, 0.5 part of calcium carbonate, 0.5 part of table salt, calcium hydrogen phosphate 0.5 part, 0.1 part of methionine hydroxy analog isopropyl ester HMBi, 0.4 part of premix.

[0026] Feed preparation method:

[0027] Step S1: Prepare the HMBi-containing premix, and mix the components in a balanced manner;

[0028] Step S2: After accurate weighing, add each component into the feed mixer one by one, mix evenly, granulate, and control the water content at about 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com